3.7 Displaying Measurement Results

39

3

Chapter 3 Measurement

If a measurement does not execute properly, a measurement fault

“- - - - -” is indicated on the display.

In addition, a measurement fault signal (ERR) is output at the EXT I/O connec-

tor.

See " ERR Output" (p.83).

A measurement fault is displayed in the following cases.

• When a test lead is not connected to the test object

• When the resistance of the measured object is over-range

Example: Attempting to measure 30 with the 300 m range selected.

• When there is a break in a probe wire

• When the contact resistance is high due to probe wear, dirt, or other factors,

or when the wiring resistance is high (see chart below)

• If the circuit protection fuse is blown

See "10.1 Troubleshooting" (p.189).

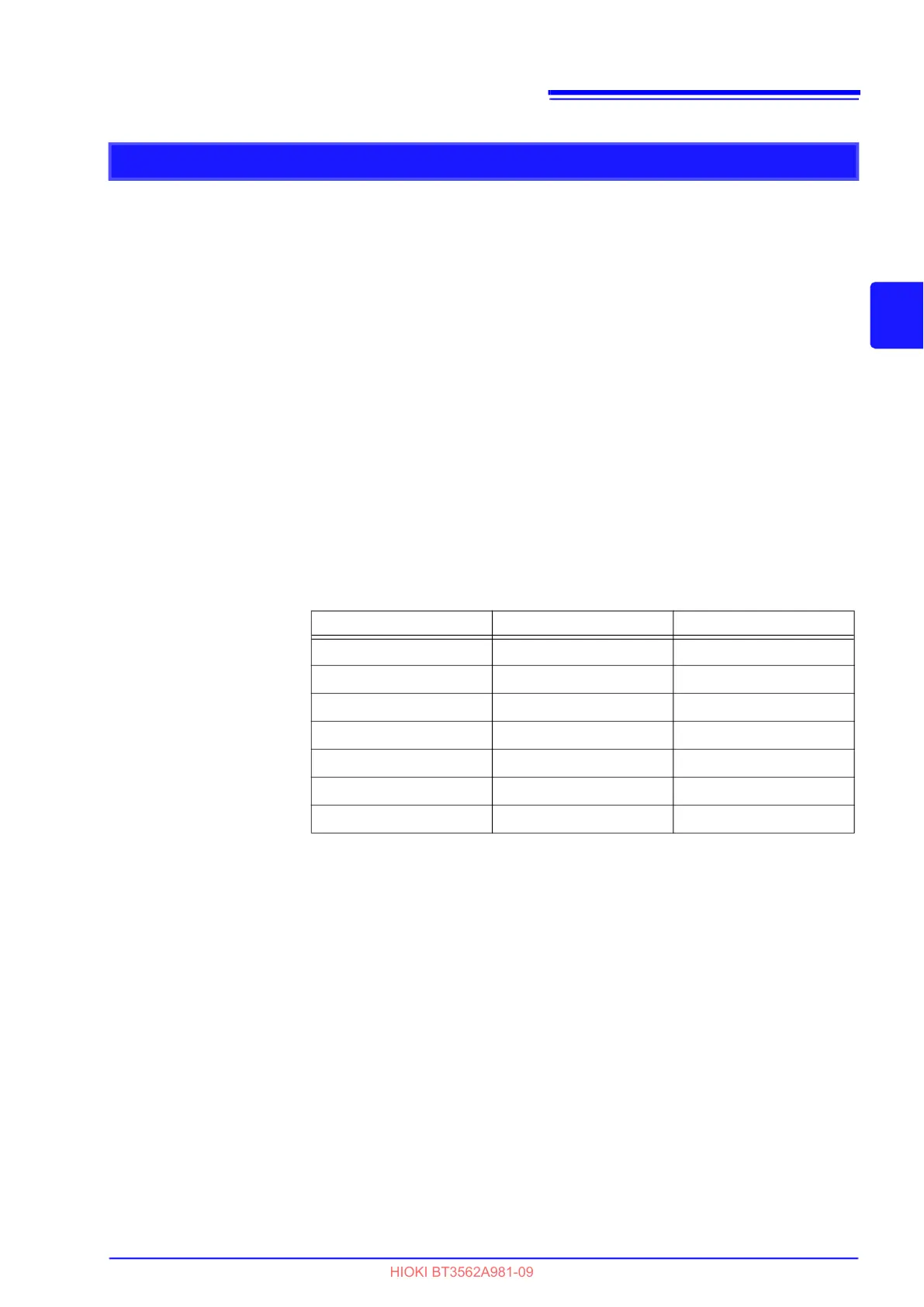

Levels at which a measurement fault is detected

A measurement fault will result when the resistance values (contact resistance +

wiring resistance + test object resistance) between the source H and L or the

sense H and L leads is greater than or equal to the values in the following table:

* Large contact resistance and/or wiring resistance values may increase the error

component in measured values. (Accuracy is not guaranteed when the sum of

contact resistance and wiring resistance is greater than or equal to 20 [for the

3 m and 30 m ranges, 2 ].)

* The instrument may be unable to detect measurement faults when the mea-

surement lead capacitance is greater than or equal to 1 nF.

Measurement Fault Detection

BT3562, BT3562-01, BT3563, BT3563-01

Range SOURCE H-L SENSE H-L

3 m 2 2

30 m

2 2

300 m 15 15

3 150 15

30

1.5 k 150

300

6 k 1.5 k

3000

6 k 15 k

Loading...

Loading...