English - 56

subsequently become the conditions for the main

circuit board to take into account in evaluating the

sensor signals. The HMI circuit board also has the task

of presenting information from the main circuit board

to the display.

The main circuit board and the HMI circuit board and

the GARDENA Smart system board contain their own

separate software. If any of these boards are replaced,

they have to be programmed via Autocheck EXP.

A new HMI circuit board contains software but, after

being tted, it must always be programmed to be

updated to latest version.

The other circuit boards do not have any software,

and consequently do not need to be programmed after

a replacement.

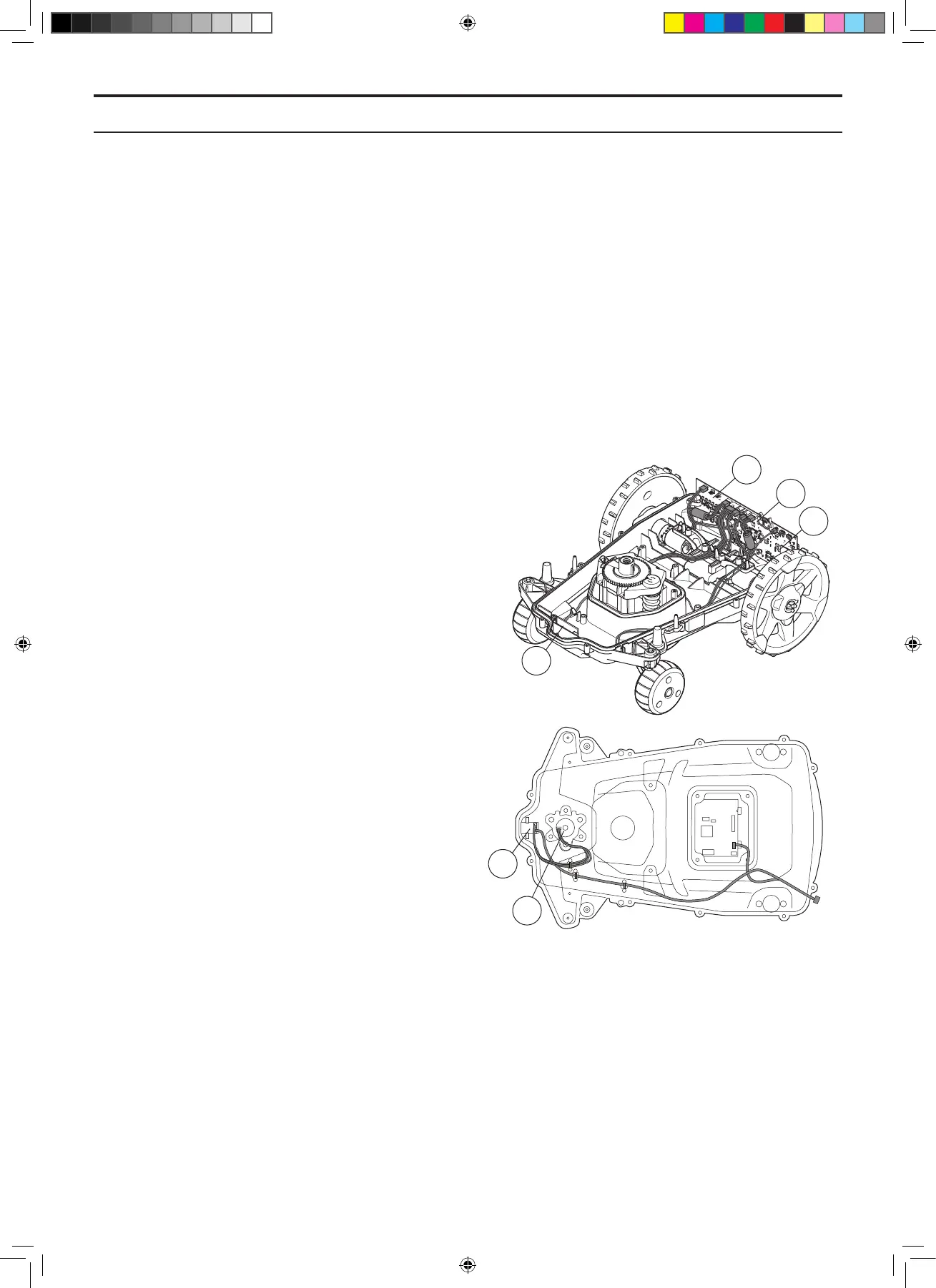

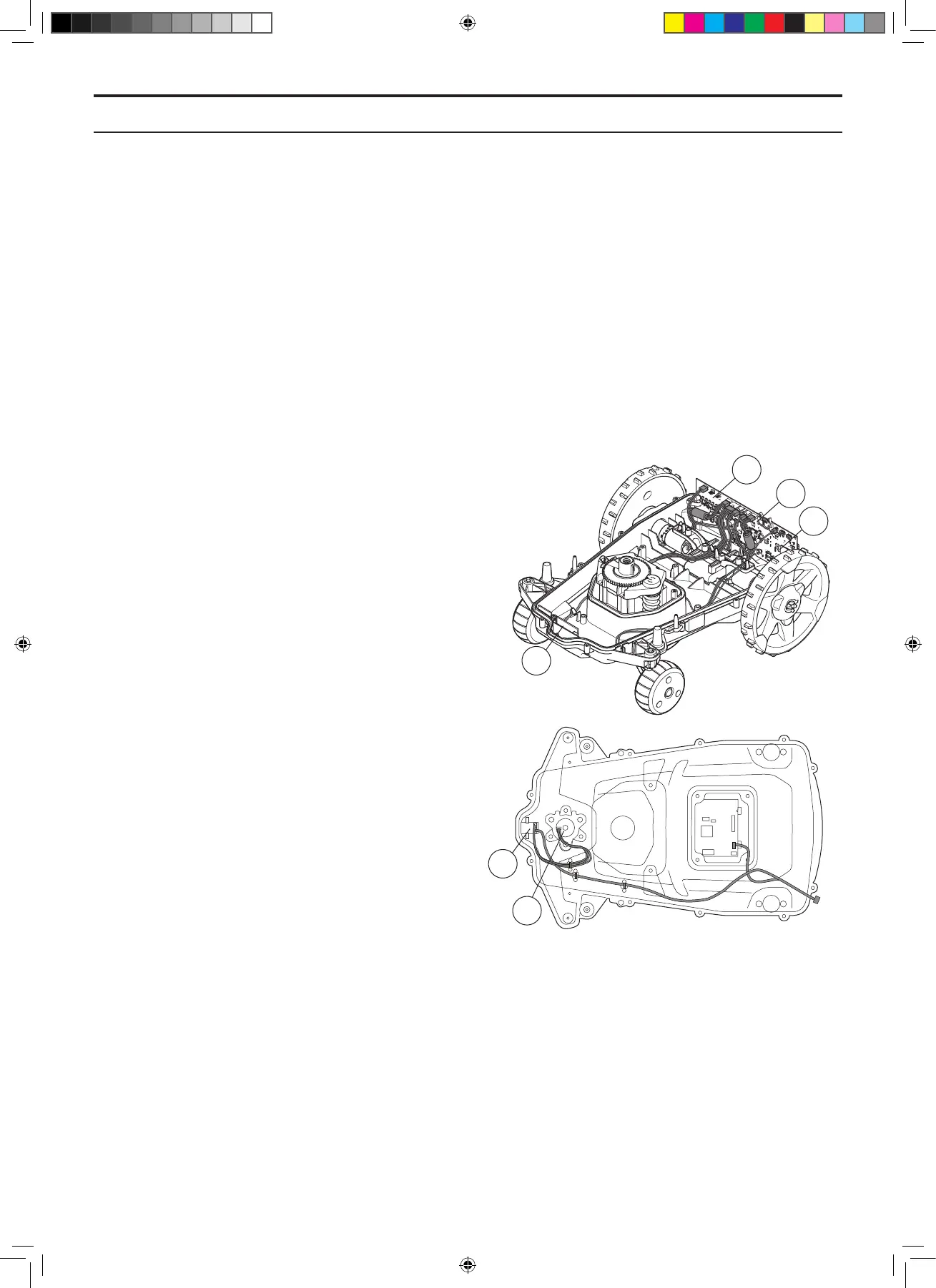

5.1.3 Sensors

The robotic lawnmower is equipped with the following

sensors:

• Front collision sensor (1)

• Rear collision sensor (2)

• Tilt sensor (3)

• Lift sensor (4)

• Rear loop sensors (5)

• Front loop sensors (6)

The tilt sensor, the rear loop sensors and the rear

collision sensor are tted on the main circuit board in

the lower section of the chassis. The other sensors are

tted to their own small circuit boards.

The sensors cannot be repaired. If troubleshooting shows

that one of the sensors is faulty, the entire circuit board

(depending on which sensor is faulty) must be replaced.

The task of the loop sensors is to measure the signals

the circuit board in the charging station sends along

the boundary loop (A signal), the guide loops (guide

signals) and the antenna plate (F and N signals).

The signals are used to control the mower and keep

the mower inside the working area.

The lift sensors and the collision sensors measure the

magnetic eld from the two permanent magnets that

are located in the body. If the magnetic eld decreases

(the distance to the magnet increases) the main

circuit board interprets that the mower has been lifted

or a collision has occurred.

The tilt sensor is an accelerometer positioned on the

main circuit board. It measures the gradient in both

X and Y axis. The value is used, among other things,

to correct the speed of the drive wheels when mowing

on steep slopes.

The current value from the sensors can be read in the

display on the mower, as well as in Autocheck EXP.

6

3

2

5

1

4

5. REPAIR INSTRUCTIONS

TH_1158203_310_315_GARDENA_US.indd 56 2016-05-11 10:16:16

Loading...

Loading...