Testing Valve Operation

General

When taking readings, account for liquid line

drop, gauge error, and thermometer accuracy.

Three measurements are required to determine

if the Valve is working properly.

Reading 1. Liquid Return Line Te m p e r a t u r e , at

the pilot valve bulb.

Reading 2. High Side Pressure, up stream of

the Flooding Valve.

Reading 3. Autosurge Valve Chamber

Pressure, through its Schrader

Valve.

Pilot Valve

When the Liquid Temperature (Reading 1) is

1 0

O

F or more below its saturation temperature

for the High Side Pressure (Reading 2), the sys-

tem should be in Surge around the Receiver.

The pilot valve operates ± 5˚F accuracy.

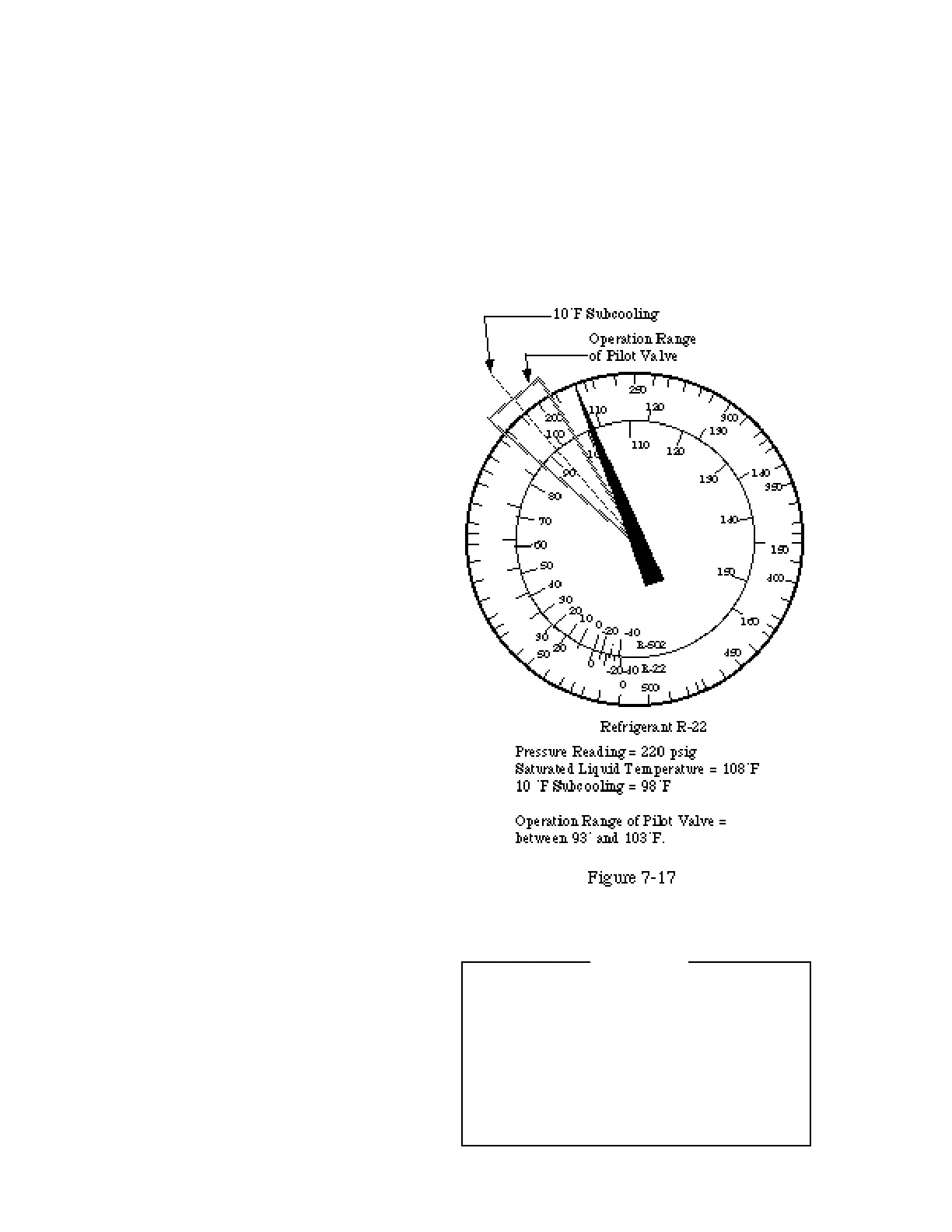

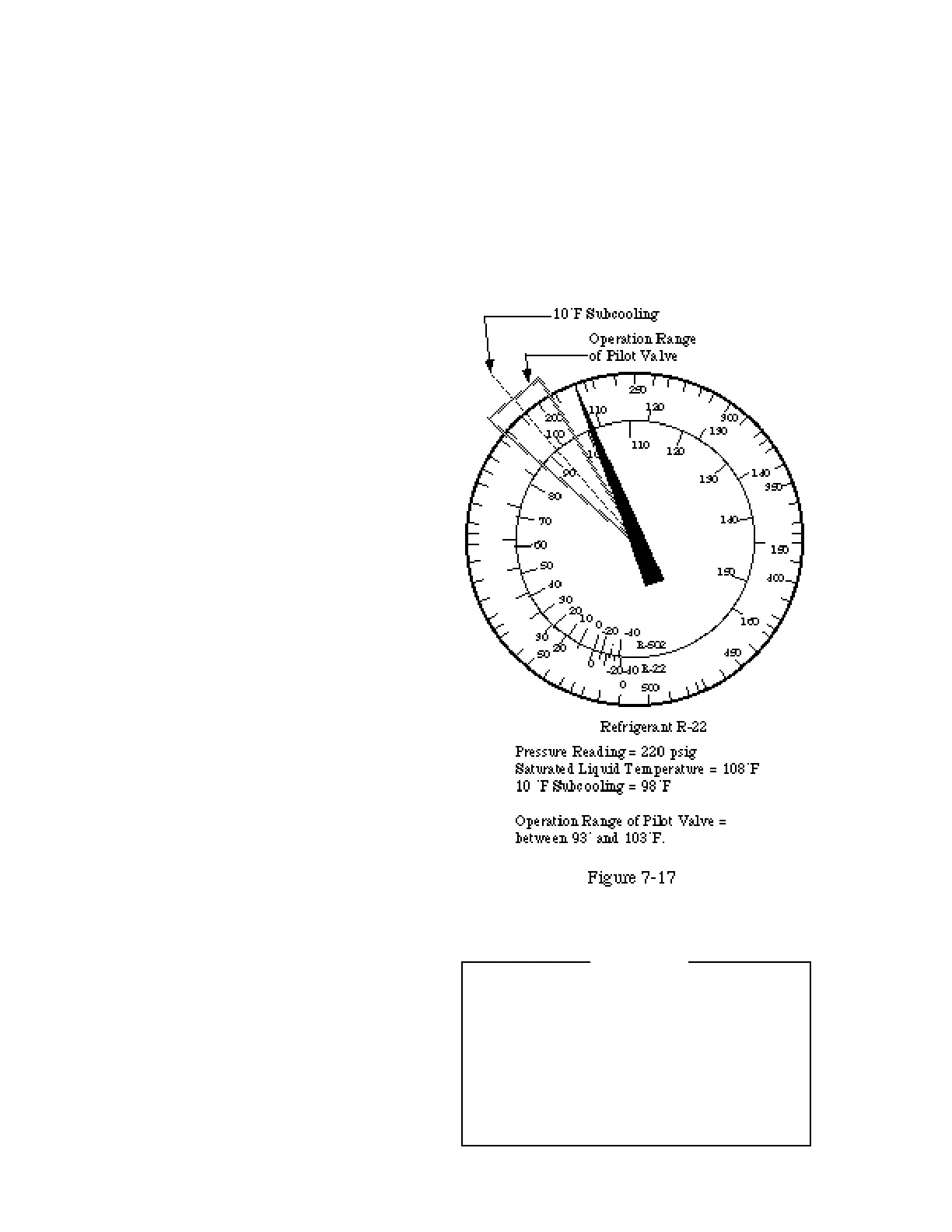

For example, a thermometer is attached to the

liquid return line at the pilot valve bulb, and a

pressure gauge is hooked up to the Liquid

Return Line up stream of the Flooding Va l v e .

The gauge face at the right shows a pressure of

220 psig (Reading 2). According to the gauge

face, R-22 would have a saturated liquid tem-

perature of 108

O

F. If the Liquid Return Line

Temperature (Reading 1) is 98

O

F, the refriger-

ant has 10

O

F of subcooling. Because of the

± 5

O

F accuracy of the pilot valve the system

may be in Surge as soon as 103

O

F is reached or

not until 93

O

F is reached.

Determining Flow Direction

When the Autosurge Valve Chamber Pressure

(Reading 3) is five pounds or more below the

High Side Pressure (Reading 2), the valve is

in Flow through the Receiver.

For example, a pressure reading at the Liquid

Return Line of 220 psig (Reading 2), and an

Mechanical Surge Valve Chamber Pressure of

215 psig should place the system in Flow

through the Receiver.

Main Valve

To test the Main Valve, isolate the Pilot Valve

and connect the Autosurge Schrader Valve to

the center hose of a manifold. Connect the

high and low side hoses to respective pressure

sources. Operate the main valve through the

gauge set.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 • Printed in USA

CONTROL VALVES Revised August 1, 1996

7 - 14

When entering a system's high side through

a Schrader Valve, use a High Side Schrader

Valve Adapter between the Schrader Valve

and the gauge speed coupling. This will

prevent excessive refrigerant loss into the

environment and decrease the hazard of

refrigerant burn.

WARNING

Loading...

Loading...