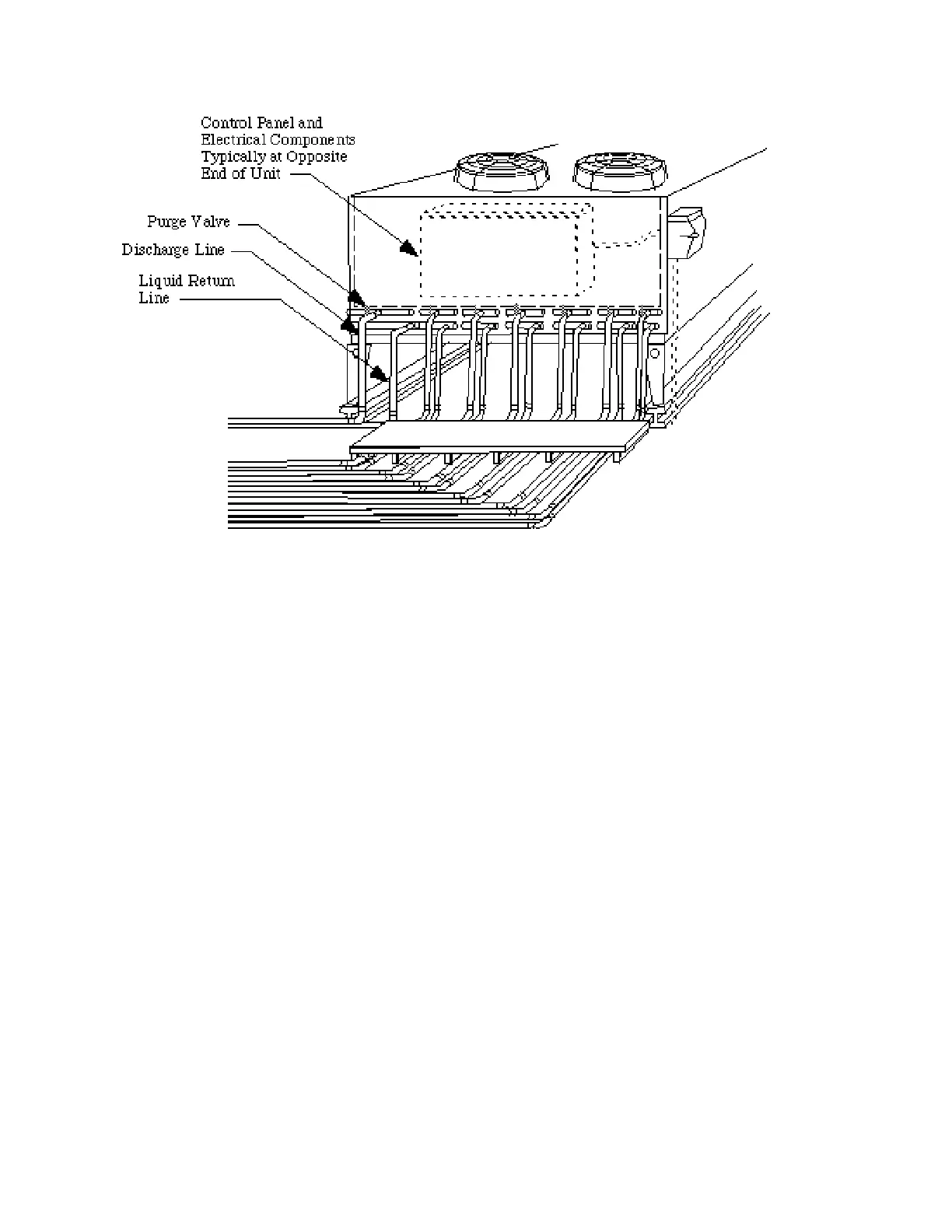

Connecting to One Manifold

Route the discharge line directly to its respec-

tive condenser inlet stub and install a purg e

valve at the highest point in the line Route the

liquid return line in a manner providing free

trapless drainage from the condenser to the

connection at the compressor unit. Horizontal

piping runs must be pitched in direction of

flow.

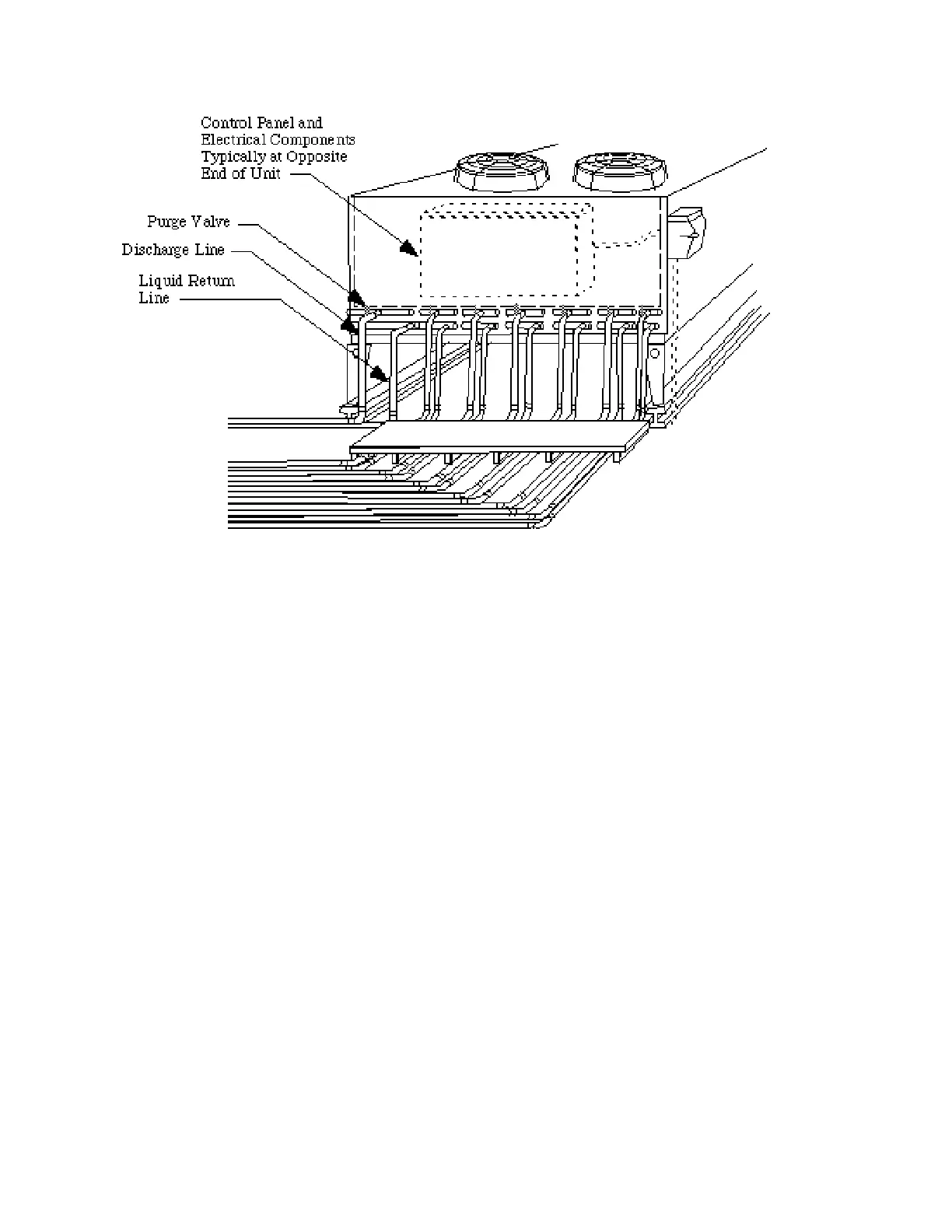

Connecting to Two Manifolds

When a compressor unit is served by two sets

of condenser circuits, an expansion loop must

be constructed between the manifolds.

Note: a connection is provided on the rack for

7

⁄8 inch equalizer line. The use of an equalizing

line is left to the discretion of the store engi-

n e e r. It is recommended that the condenser

m a n u f a c t u r e r’s installation instructions be

consulted. When used, the equalizing line

should have a field supplied check valve

installed to prevent flow from the condenser

to the receiver. A s h u t o f f valve should be

installed on the condenser side of the check

valve. Normally, equalizer lines are not

required unless the condensate lines are

trapped and/or undersized.

1. D i s c h a r ge line: Connect the two inlet

stubs to the discharge line by forming an

expansion loop extending at least

1 2 inches away from the manifolds. Do

not route the discharge line directly in

front of the control panel.

2. Liquid return line: Route each liquid

return line downward at least 6 f e e t

between outlet stubs before teeing into

the main liquid return line. (Note: If split

condenser valving is not used, drop may

be reduced to 2 feet.) After the tee, route

the main liquid return line in a manner

providing free trapless drainage from the

condenser to the connection at the com-

pressor unit.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 • Printed in USA

CONDENSER INSTALLATION Addendum – April 15, 1996

A - 4

Figure A-3. Connecting to One Manifold

Loading...

Loading...