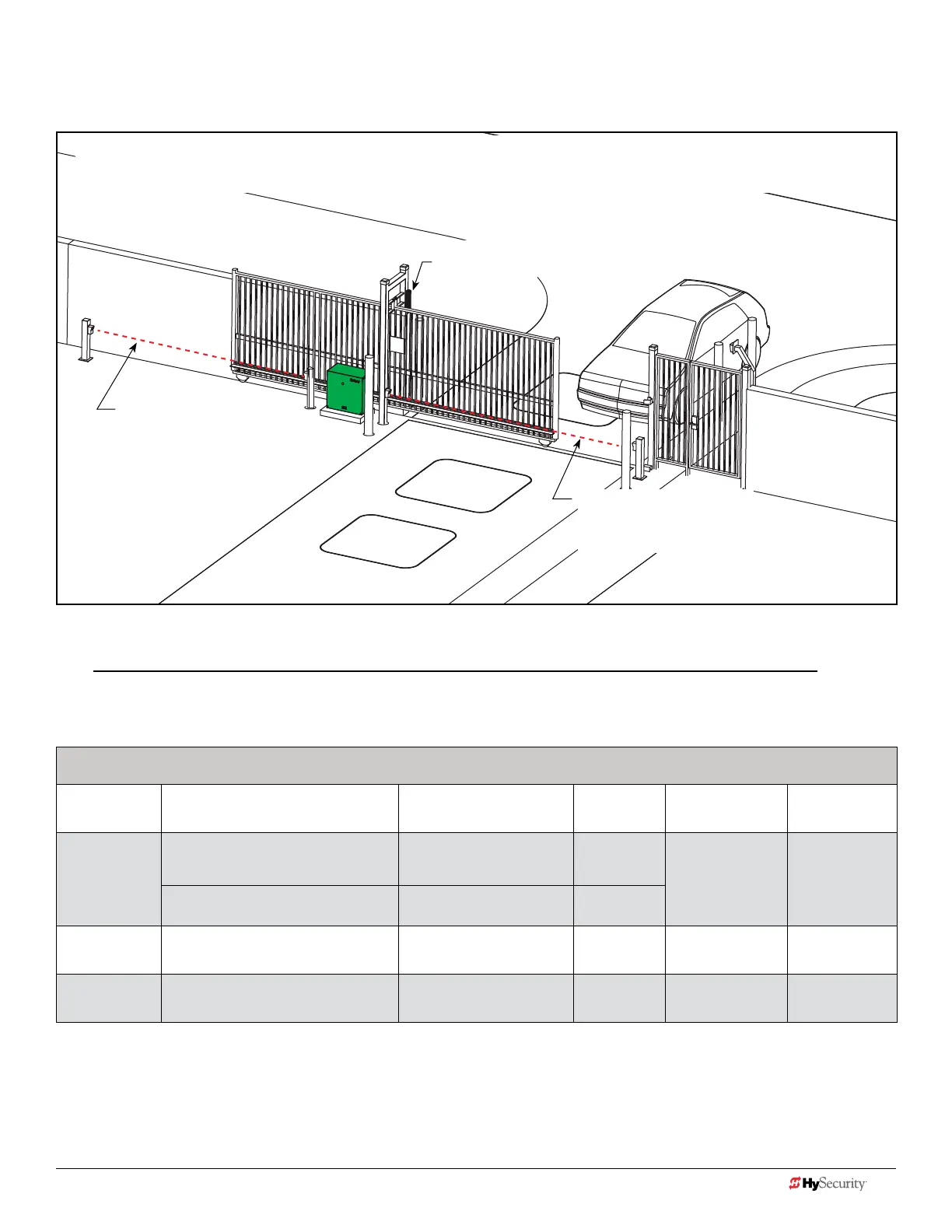

dIaGram 1: typIcaL SLIde Gate SIte aSSeSSment

NOTICE: HySecurity slide gates are equipped with a Type A inherent entrapment sensor (IES) that complies with

UL 325. Any impediment to gate travel causes the gate to stop and reverse.

Monitored external entrapment protection sensors, which can be used in this site scenario and are compatible with

HySecurity slide gates, appear in the following chart. For a full list, refer to page 6.

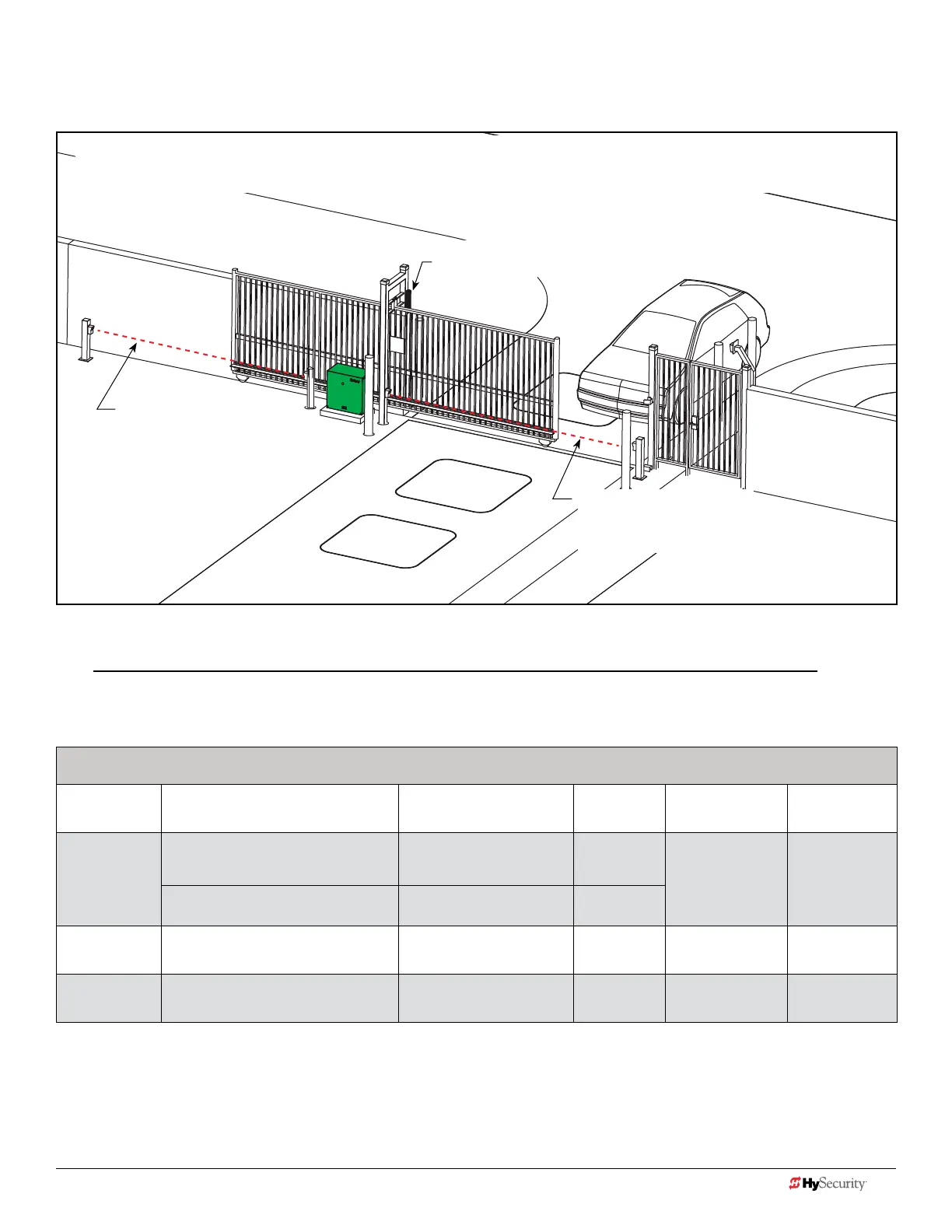

EXAMPLE: External Entrapment Protection Sensors: Normally Close Contact, Compatible with HySecurity Gate Operators

P/N 2016 Monitored Sensors Sensor Type Output Manufacturer

UL 325

Recognized

MX3981

MX3983

Wired Gate Edge Sensor

MGR20-2U-05-T2, Round

Wraparound edge

(5 ft for 2" round post)

10K

Resistor

Miller Edge Type B2

Gate Edge Module (GEM -104) Edge Interface Module

Normally

Closed

MX3990 IRB-MON (Dist.~ 65 ft)t Thru-beam photo eye

Normally

Closed

EMX Industries Type B1

MX3990 IRB-MON (Dist.~ 65 ft) Thru-beam photo eye

Normally

Closed

EMX Industries Type B1

A minimum of one monitored external entrapment protection sensor, in addition to the slide gate operator’s inherent

sensor, is required before enabling momentary control activation. However, if there is a risk of entrapment in both

directions of gate travel, then both directions of travel must be protected by an external sensor.

NOTE: At minimum, external entrapment protection sensors must be installed wherever potential for entrapment exists during gate

movement. Note that every site is different. All potential entrapment zones should be protected with contact or non-contact

sensors. HySecurity gate operators detect NC output sensors and monitor them to comply with UL 325 Standard of Safety.

NOTE: This scenario shows a possible conguration with the minimum recommended external entrapment protection sensors.

Other sensor congurations are valid. Each gate site is different. It is the installer's responsibility to assess and protect all

entrapment zones.

Drawing is not to scale

Photo eye thru-beam

protecting Trailing End of

gate (Open direction of

travel)

Photo eye thru beam

protecting Leading End of

gate (Close direction of travel)

Edge sensor

(protecting open

direction) Draw-in

zones

18 D0726 Rev. J UL 325 - 2016 HySecurity Monitored Sensors © 2016 www.hysecurity.com

www.hysecurity.com © 2016 Quick Start D0726 Rev. J 19

Loading...

Loading...