SD1 Series Inverters Fault Tracking

-102-

Chapter 6 Fault Tracking

6.1 Fault Prevention

This chapter describes how to carry out preventive maintenance on inverters.

6.1.1 Periodical maintenance

If the inverter is installed in an environment that meets requirements, little maintenance is

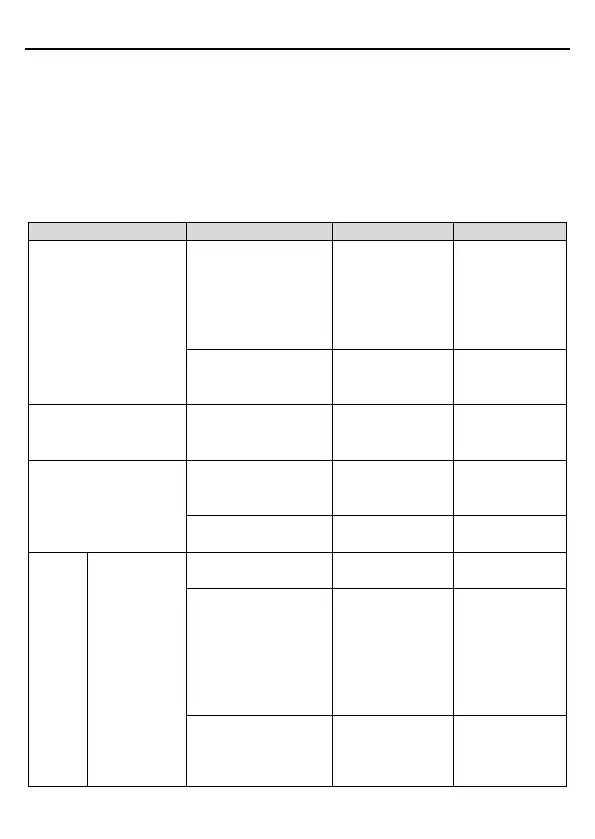

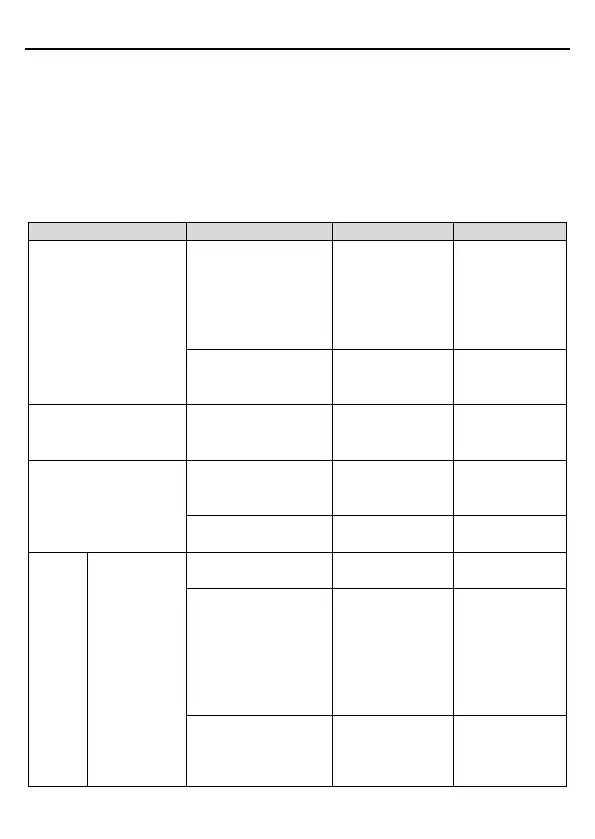

needed. The following table describes the routine maintenance periods recommended by IMO.

For more detailed information on maintenance, please contact us.

Ambient environment

temperature, humidity

and vibration and

ensure there is no dust,

gas, oil fog and water

Visual examination

and instrument

test

Conforming to the

manual.

Ensure there are no

tools or other foreign or

Visual examination

There are no tools

or dangerous

Voltage

and control circuit are

Measurement by

multimeter

Conforming to the

manual.

Keypad

Ensure the display is

clear enough

Visual examination

The characters

are displayed

Ensure the characters

are displayed totally

Visual examination

Conforming to the

manual.

Main

circuit

For public use

Ensure the screws are

Tighten up NA

distortion, cracks,

damage or

color-changing caused

by overheating and

aging to the machine

Visual examination NA

Ensure there is no dust

and dirtiness

Visual examination

NA

Note:

if the color

of copper blocks

change, it does

Loading...

Loading...