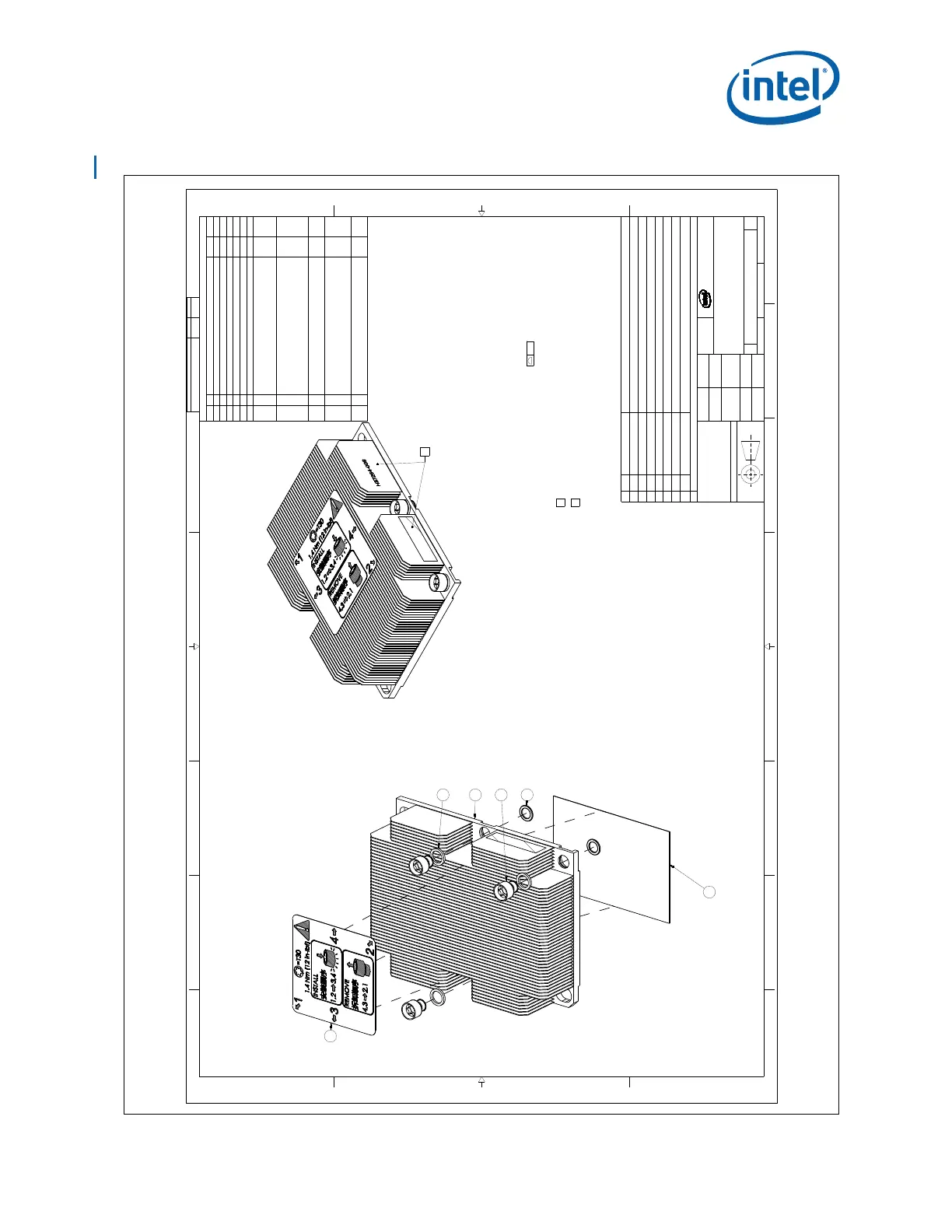

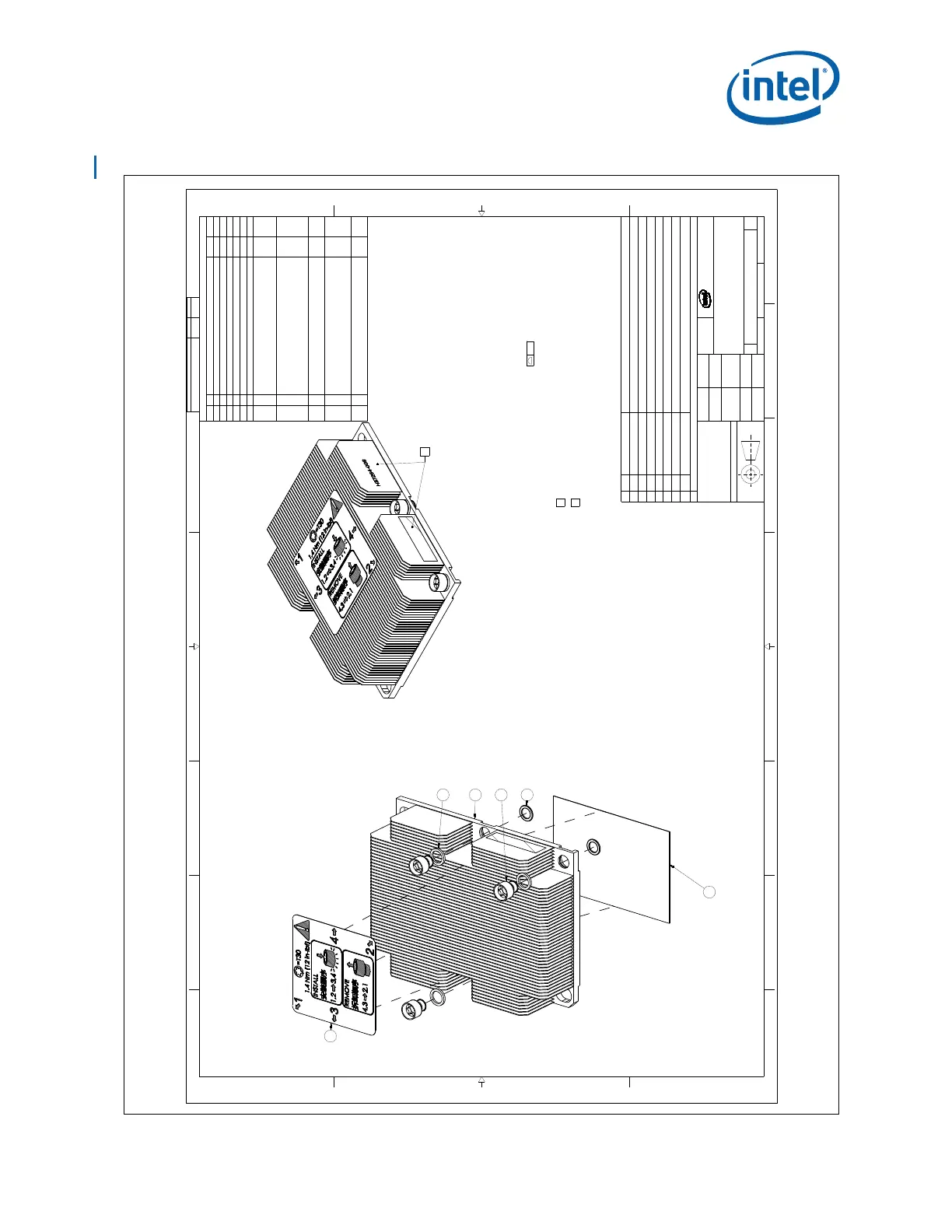

Figure E-29. 1U Heatsink Assembly, 1/2 (Reference Only)

13

4

5678

B

C

D

A

123

4

5678

B

C

D

A

2200 MISSION COLLEGE BLVD.

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

R

0.24

H37264 1 L

DWG. NO SHT. REV

SHEET 1 OF 2

DO NOT SCALE DRAWING

SCALE: 2

LH37264D

REV

DRAWING NUMBER

SIZE

KNL 1U HEATSINK ASSEMBLY

TITLE

DEPARTMENT

SEE NOTESSEE NOTES

FINISHMATERIAL

DATEAPPROVED BY

3/10/17

DATECHECKED BY

3/10/17

DATEDRAWN BY

3/10/17

DATEDESIGNED BY

DIMENSIONS ARE IN MILLIMETERS

THIRD ANGLE PROJECTION

PARTS LIST

DESCRIPTIONPART NUMBER

ITEM NO

QTY

KNL 1U HEATSINK ASSEMBLYH37264-009TOP

KNL 1U HEAT SINKG97766-00711

SKT-P DELRIN HEATSINK WASHERH37265-00424

TIM PCM45F, 47X70MMH38442-00131

KNL HS LABELH79111-00241

SKT -P HEATSINK COLLARH94875-00454

SKT-P-KNL, HEATSINK NUT, M4H94876-00364

REVISION HISTORY

ZONE REV DESCRIPTION DATE APPR

- A PRELIMINARY ASSEMBLY RELEASE 2/14/14

- B UPDATED; NUT, WASHER, AND HEATSINK. ASM REV TO -002 3/5/14

C UPDATED HEATSINK G97766 TO -004, ASM H37264 TO -003 3/20/14

D UPDATED HEATSINK G97766 TO -005, ASM H37264 TO -004 05/09/14

E

UPDATED M4 NUT -004 AND IS REFLECTED IN BOM TABLE 05/16/14

F UPDATED VIEW TO SHOW NOTCH DEPTH 05/23/14

G

1. ADDED TWO ADDITIONAL NUTS, COLLARS, AND WASHERS

2. ADDED LABEL PART NUMBER TO BOM

3. UPDATED NOTES

4. ROLLED ASSEMBLY PART NUMBER FROM -004 TO -005.

5. NUT CHANGED FROM -004 TO -006.

3/31/15

H

1. REPLACED H19326-005 M4 NUT TO A NEW T-30 TORX NUT

H94876-002

2. CHANGED HEATSINK DELRIN WASHER INNER DIAMETER TO

H37265-004

3. REPLACED HS COLLAR H19327-001 WITH NEW DELRIN COLLAR

H94875-001

4. ROLLED H37264-005 TO H37264-006

10/5/15

J

1. REPLACED DELRIN HS COLLAR H94875-001 WITH NYLON HS

COLLAR H94875-002.

2. ROLLED H37264-006 TO H37264-007

12/21/15

K

1. NEW LABEL PART NUMBER FROM H79111-001 TO H79111-002.

2. NEW NUT PART NUMBER FROM H94876-002 TO H94876-003.

3. ROLLED ASSEMBLY PART NUMBER FROM H37264-007 TO

H37264-008.

4. UPDATED NOTE 5 TO REMOVE THE TORQUE SPEC MARKING, NOW

ON LABEL.

10/24/16

L

1.COLLAR DESIGN UPDATED TO H94875-004

2.ITEM IDENTIFICATION UPDATED TO H37264-009

3/10/17

NOTES:

1. REFERENCE DOCUMENTS

ASME Y14.5M-2009 - STANDARD DIMENSION AND TOLERANCES

UL1439 - UL SHARP EDGE TESTING

2. FEATURES NOT SPECIFIED ON THE DRAWING SHALL BE CONTROLLED BY THE 3D DATABASE.

FOR FEATURES NOT EXPLICITLY TOLERANCED:

(BASIC DIMENSION FROM 3D CAD MODEL).

3. REMOVE ALL BURRS, SHARP EDGES, GREASES, AND/OR SOLVENTS AFTER FINAL ASSEMBLY.

4 MINIMUM PUSH OUT FORCE = 10 LBF PER COLLAR/NUT.

5 PLACE INTEL PART NUMBER AND SUPPLIER DATE CODE. DISPLAY TEXT IN ALLOWABLE AREA

ON EITHER SIDE OF PART. THE MARK CAN BE AN INK MARK, LASER MARK, PUNCH MARK

OR ANY OTHER PERMANENT MARK THAT IS READABLE AT 1.0X MAGNIFICATION.

5

1

2

3

4

5

6

Loading...

Loading...