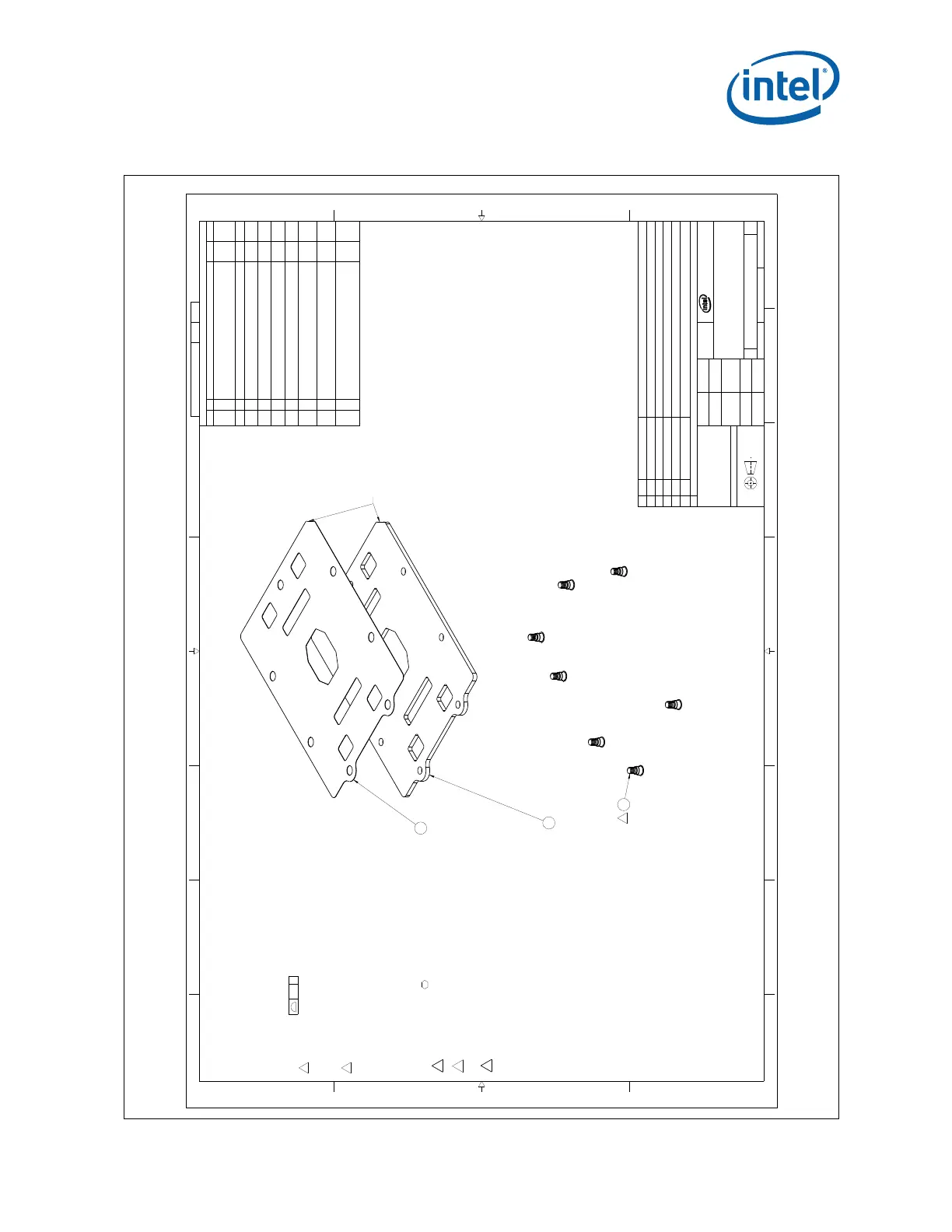

Figure E-1. Backplate Assembly, 1/3

13

4

5678

B

C

D

A

123

4

5678

B

C

D

A

2200 MISSION COLLEGE BLVD.

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

R

.24 A

H77469 1 09

DWG. NO SHT. REV

SHEET 1 OF 3

DO NOT SCALE DRAWING

SCALE: 2:1

09H77469D

REV

DRAWING NUMBER

SIZE

KNL BACKPLATE ASSY

TITLE

DEPARTMENT

SEE NOTESSEE NOTES

FINISHMATERIAL

-

DATEAPPROVED BY

08/14/13

DATECHECKED BY

08/14/13

DATEDRAWN BY

08/14/13

DATEDESIGNED BY

DIMENSIONS ARE IN MILLIMETERS

THIRD ANGLE PROJECTION

PARTS LIST

DESCRIPTIONPART NUMBER

ITEM NO

QTY

KNL BACK PLATE ASSEMBLYH77469-002TOP

KNL BACK PLATEG93719-00211

KNL BACK PLATE STUDH12853-00427

KNL BACK PLATE INSULATORG93724-00231

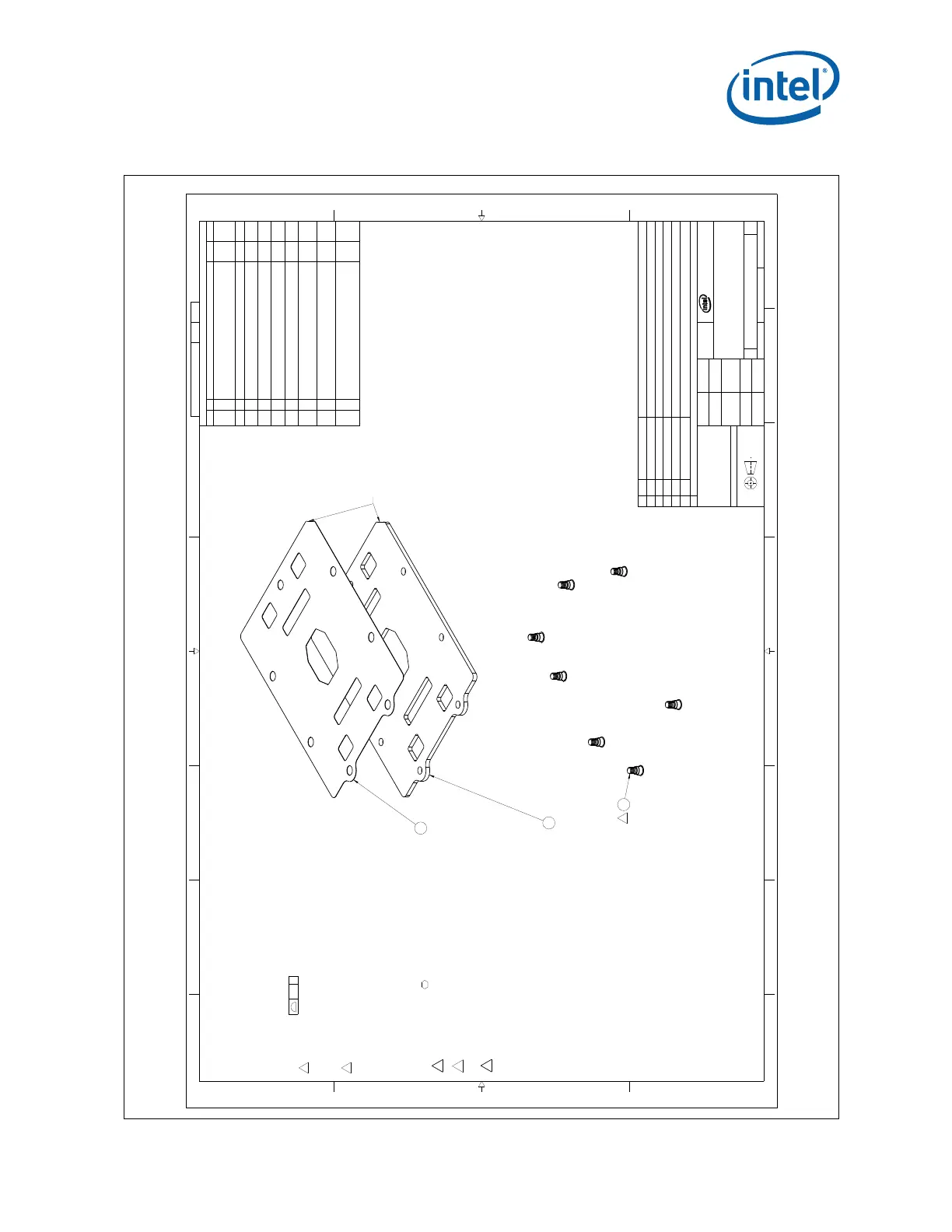

REVISION HISTORY

ZONE REV DESCRIPTION DATE APPR

- 01 TOOLING RELEASE 03/26/15

PG2 7-C

PG2 6-A

02

1. ADDED DATUM B

2. FIXED GD & T DIMENSION CALL OUT

4/1/15

03

1. UPDATED REV ON PART TO MATCH DRAWING.

2. ADDED SHEET 4 FOR BOLSTER PLATE AND MATERIAL CALLOUT.

3. ADDED NOTE 9.

4/15/15

PG2 7A

04

1. ADDED NOTE 9 TO CALL OUT CRITICAL TO FUNCTION DIMENSIONS.

2. REINSTATED DRAWING G93719 AND REMOVED SHEET 4.

3. CHANGED DIMENSION TOLERANCE RANGE.

5/7/15

PG2 6A 05

1. REMOVED PLATE THICKNESS CRITICAL TO FUNCTION CALLOUT,

SHOWN ON BOLSTER PLATE DRAWING.

6/29/15

PG1 7C 06

1. UPDATED NOTE 4 TO LOWER THE PULLOUT FORCE FROM 1110N TO 267N.

2. ADDED NOTE 10 AND 11.

9/1/15

PG2 A3

PG2 B2

PG1 B8

PG1 C7

07

1. CHANGED TRUE POSITION TOLERANCE FROM 0.1 TO 0.15

2. REMOVED THE PROFILE TOLERANCE DIMENSION. USE NOTE 2.

3. ADDED NOTE 12

4. REMOVED NOTE 5 WORDING.

10/20/15

PG2 B6 08

1. OVERALL STUD DIMENSION CHANGED FROM 6.334 TO 6.80

2. ROLLED PART NUMBER FROM H77469-001 TO H77469-002.

2/11/16

PG1 A3

PG2 A3

PG3 D6

PG3 B3

PG1 A3

PG1 C7

09

1. REMOVED DATUM B AND UPDATED NOTE 2 TO REFLECT THE CHANGE.

2. REMOVED CTF DIMENSION

3. ADDED CTF DIMENSION

4. REMOVED THE WORD "PRODUCTION" FROM THE ASSEMBLY

5. UPDATED PART NUMBER TABLE FOR THE STUD FROM -003 TO -004.

6. MODIFIED NOTE 3C TO REMOVE THE PART NUMBER REVISION.

7/18/16

NOTES; UNLESS OTHERWISE SPECIFIED:

1. REFERENCE DOCUMENTS

ASME Y14.5M-2009 - STANDARD DIMENSION AND TOLERANCES

164997 - INTEL MARKING STANDARD

2. FEATURES NOT SPECIFIED ON DRAWING SHALL BE CONTROLLED BY

3D CAD DATABASE. FOR FEATURES NOT EXPLICITLY TOLERANCED:

(BASIC DIMENSION FROM 3D CAD MODEL):

3 MARK ASSEMBLY PART APPROXIMATELY WHERE SHOWN PER

INTEL MARKING STANDARD (G14577) WITH ADDITIONAL

INFORMATION:

A) ASSEMBLY VENDOR ID

B) DATE CODE

C) INTEL PART NUMBER

4 ATTACH STUDS:

- PULL OUT FORCE > 667N (150 LBF)

- TORQUE OUT > 2.25N-m (20 IN-LBF)

- FAILURE MODES: STUDS (7) MUST NOT SHEAR, DEFORM,

STRIP, CRACK, OR TORQUE-OUT BELOW TORQUE LIMIT.

5. NOT USED

6. CLEAN AND DEGREASE BACKPLATE ASSEMBLY BEFORE ATTACHING

INSULATION.

7. AFTER APPLICATION THE INSULATOR MUST BE FREE OF BUBBLES,

POCKETS, CREASES, AND ANY OTHER DEFORMATIONS.

8. FINAL ASSEMBLY SHALL BE FREE OF OIL AND DEBRIS.

9. DIMENSIONS MARKED ARE CRITICAL TO FUNCTION

DIMENSIONS (CTF).

10 INSTALL ALL STUDS FLUSH TO THIS SURFACE, NOT PROTRUDING

BEYOND BACKPLATE SURFACE.

11 BACKPLATE ASSEMBLY TO BOLSTER PLATE ASSEMBLY (H77470)

STUD/NUT MUST BE ABLE TO ENGAGE WITH MOTHERBOARD THICKNESS'

IN THE RANGE OF 1.42MM-2.69MM (0.056"-0.106").

12 FLATNESS MUST BE MEASURED IN THE UNCONSTRAINED STATE. ALL

OTHER CTF MEASUREMENTS CAN BE MEASURED IN THE CONSTRAINED

STATE.

4

7X

2

1

3

USE PIN 1 CHAMFER FOR ORIENTATION OF INSULATOR TO BACK PLATE

C

Loading...

Loading...