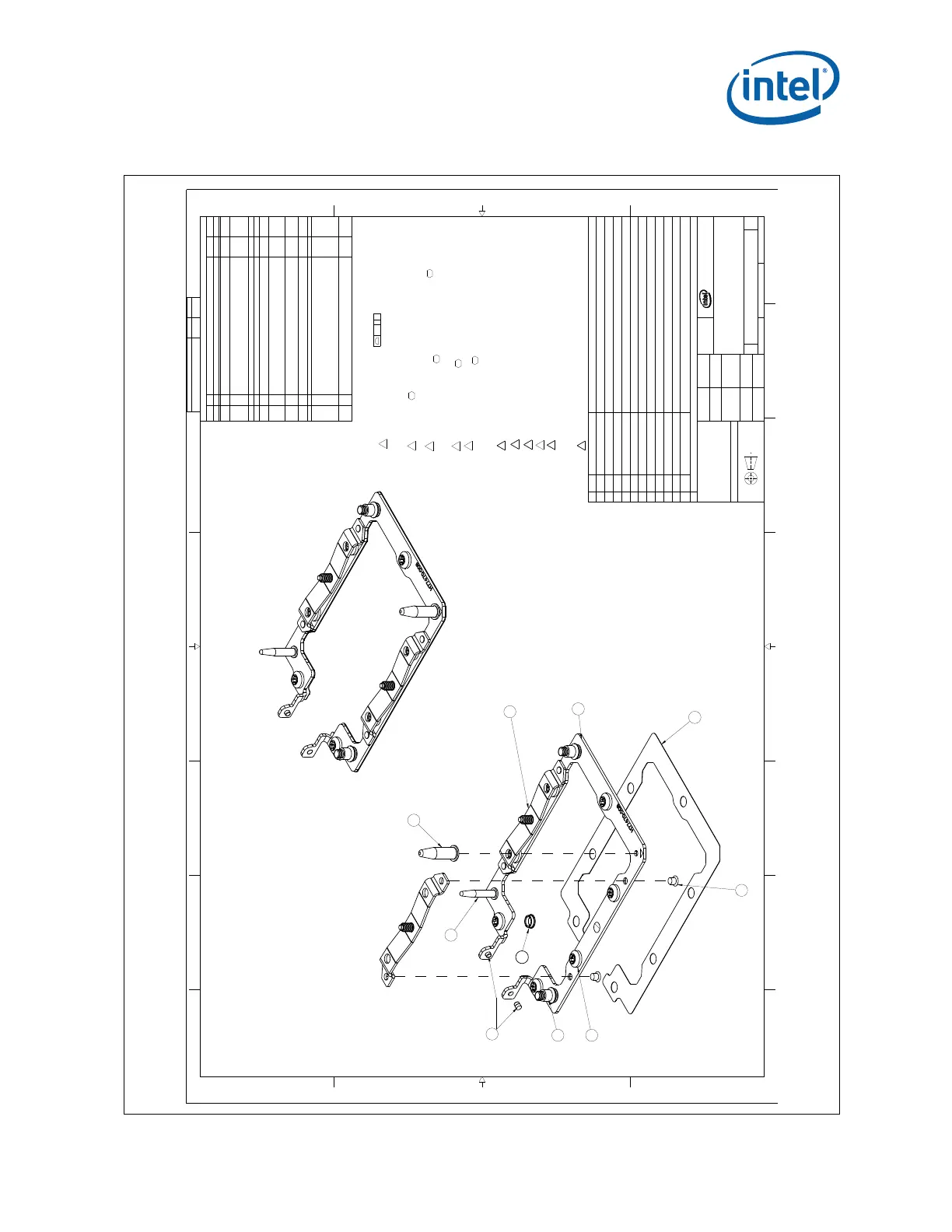

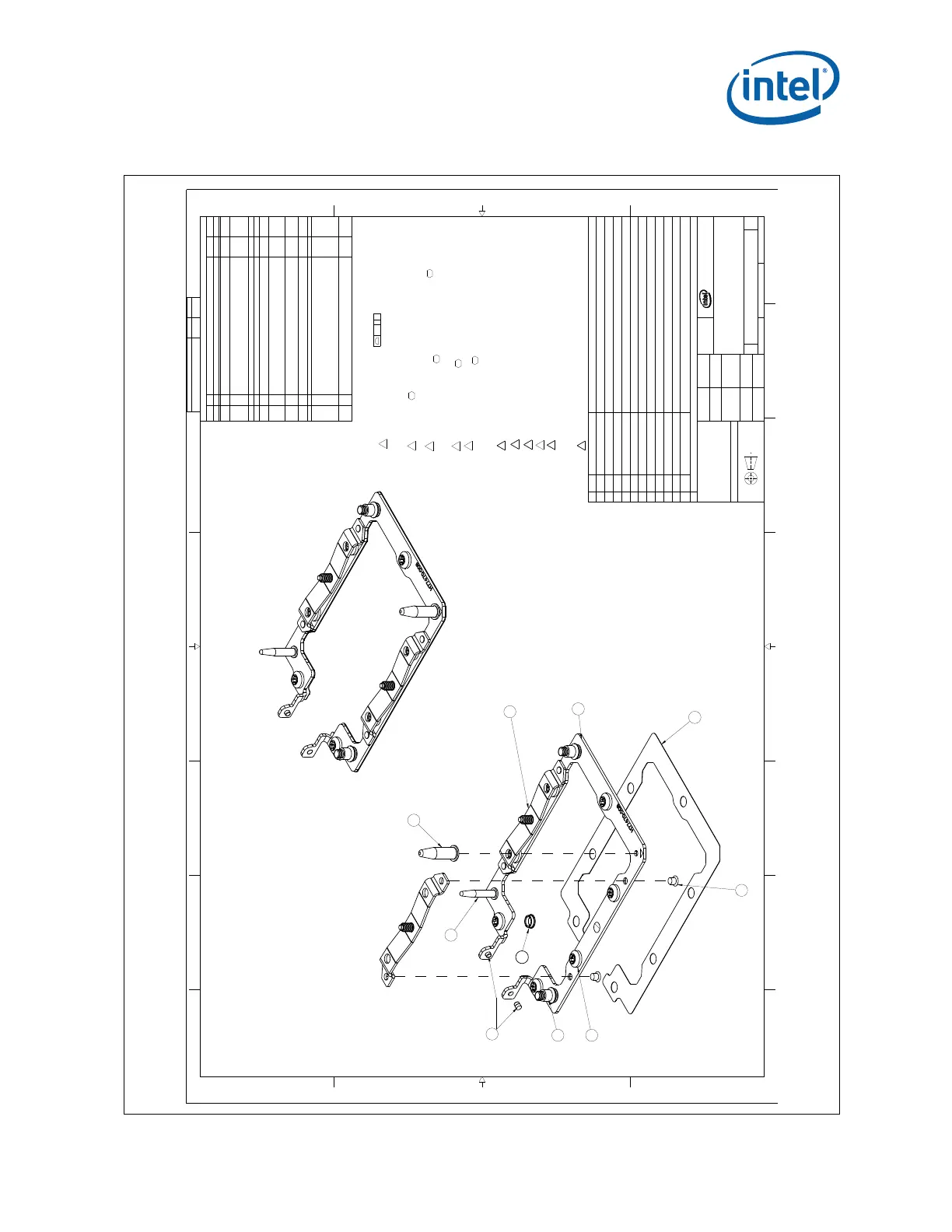

Figure E-5. Bolster Plate Assembly, 1/2

13

4

5678

B

C

D

A

123

4

5678

B

C

D

A

2200 MISSION COLLEGE BLVD.

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

R

0.2 A B

REVISION HISTORY

ZONE REV DESCRIPTION DATE APPR

-01

TOOLING RELEASE

4/8/15

02

1.UPDATED NOTE #8 TO LOWER PULLOUT FORCE FROM 225 LBF TO 60 LBF

2. ROLLED ASSEMBLY PART NUMBER FROM -001 TO -002

.

4/15/15

PG2 B6

03

1. MODIFIED NOTE 4 CALL-OUT SYMBOL FOR CRITICAL TO

FUNCTION DIMENSIONS.

2. ROLLED ASSEMBLY PART NUMBER FROM -002 TO -003,

BASED ON UPDATED SPRING, COLLAR AND M4 STUD CHANGES.

3. DIMENSION CHANGED FROM 72.7MM TO 72MM

5/6/15

PG2 A7 04

1. REMOVED DIMENSION.

5/12/15

PG2 5C 05

1. MOVED CTF CALLOUT TO FEATURE CONTROL FRAME.

5/22/15

06

1. CHANGED STUD PART NUMBER IN SPRING.

2. CHANGED BOLSTER HOLE DIAMETER UNDER SPRINGS.

6/9/15

PG2 D5

07

1. CHANGED DATUM B REFERENCE FROM NUT TO SMALL GUIDE POST

2. ROLLED THE PART DASH NUMBER FROM H77470-004 TO H77470-005

3. UPDATED NOTE 8 TO REMOVE PUSHOUT FORCE REQUIREMENT

4. ADDED NOTE 14

8/28/15

PG1 B3

PG2 C6

08

1. ROLLED DASH NUMBER FROM H77470-005 TO H77470-006 BASED ON

INSULATOR HOLE DIAMETER CHANGE

2. ADDED NOTE 15 AND 16

3. CHANGED POSITION TOLERANCE FROM 0.1 TO 0.25.

10/20/15

PG1 B3

PG2 B3

09

1. ROLLED DASH NUMBER FROM H77470-006 TO H77470-007 BASED ON

NEW SPRING ASSEMBLY (DECREASED SPRING STUD LENGTH) AND

PRECONDITIONING NOTE 17.

12/7/15

PG2 A1 10

1. REMOVED CTF DIMENSION AND CHANGED TO A REFERENCE DIMENSION.

2/11/16

PG2 D7

PG2 B3

PG1 C2

11

1. CHANGED DATUM B TO THE CORNER STANDOFFS. MEASUREMENTS TAKEN

FROM THE CENTER OF THE PART.

2. CHANGED PRE-CONDITIONING PUSH DISTANCE FROM 2.8 TO 3.1.

3. CHANGED NOTE #8 FROM PULLOUT FORCE FROM 60 LBF TO 100 LBF.

4. REMOVED COSMETIC REVISION OFF THE PART.

5. INCREASED TRUE POSITION TOLERANCES FOR GUIDE POSTS, CORNER

STANDOFFS AND SPRING STUDS.

6. ROLLED ASSY DASH NUMBER FROM H77470-007 TO H77470-008 BASED ON NEW

SPRING ASSEMBLY NUMBER (ADDED HARDNESS REQUIREMENT ON SPRING STUD).

6/3/16

PG2 D7

PG2 C5

PG2 A4

PG2 B3

12

1. CHANGED LOCATION OF CTF SYMBOL FROM GUIDE POSTS TO CORNER STANDOFFS.

2. ADDED BACK CTF SYMBOL ON THE CENTER STUD DIMENSION.

3. REMOVED CTF SYMBOL ON THE SPRING STUD TO BOLSTER FRAME GAP DIMENSION.

4. REMOVED COSMETIC TEXT "PRE-PRODUCTION" FROM ASSEMBLY.

7/18/16

H77470 1 12

DWG. NO SHT. REV

SHEET 1 OF 2

DO NOT SCALE DRAWING

SCALE: 2:1

12H77470D

REV

DRAWING NUMBER

SIZE

KNL BOLSTER PLATE ASSEMBLY

TITLE

DEPARTMENT

SEE NOTESSEE NOTES

FINISHMATERIAL

DATEAPPROVED BY

-

9/18/15

DATECHECKED BY

8/16/13

DATEDRAWN BY

8/16/13

DATEDESIGNED BY

DIMENSIONS ARE IN MILLIMETERS

THIRD ANGLE PROJECTION

REVISION HISTORY

ZONE REV DESCRIPTION DATE APPR

--- -

NOTES; UNLESS OTHERWISE SPECIFIED:

1. REFERENCE DOCUMENTS

ASME Y14.5M-2009 - STANDARD DIMENSION AND TOLERANCES

164997 - INTEL MARKING STANDARD

2. FEATURES NOT SPECIFIED ON DRAWING SHALL BE CONTROLLED BY 3D CAD DATABASE.

FOR FEATURES NOT EXPLICITLY TOLERANCED:

(BASIC DIMENSIONS FROM THE 3D CAD DATABASE)

3 MARK ASSEMBLY PART APPROXIMATELY WHERE SHOWN PER INTEL MARKING STANDARD

(164997) WITH ADDITIONAL INFORMATION:

A) ASSEMBLY VENDOR ID

B) DATE CODE

C) DISPLAYED TEXT

D) DISPLAYED PIN-1 MARKING

4 DIMENSIONS MARKED ARE CRITICAL TO FUNCTION DIMENSION (CTF). FOR PRODUCTION QUALIFICATION

INDICATED DIMENSION REQUIRES CP/CPK STUDY BASED ON A RANDOM 30 PART SAMPLE OF A 300 PART MINIMUM

LOT PER CQC.

5 ALL STUDS/RIVETS/POSTS/WELDS TO BE FLUSH TO THIS SURFACE, +0.00 / -0.25

6 SPRING RIVETS (INDIVIDUAL):

- PULLOUT FORCE > 500N (112LBF)

- FAILURE MODES: MUST NOT SHEAR, DEFORM, STRIP, OR CRACK BELOW FORCE LIMIT.

- LIMITS BASED ON 3 SIGMA DISTRIBUTION

- RIVET HEAD SOLID HEIGHT MUST BE GREATER THAN OR EQUAL TO SPRING TOP SURFACE.

7 NUT/COLLAR SEPARATION FORCE

- PUSHOUT FORCE > 222N (50LBF)

- LIMITS BASED ON 3 SIGMA DISTRIBUTION

8 CORNER STANDOFF SEPARATION FORCE

-PULLOUT FORCE > 445N (100LBF)

-TORQUE OUT > 2.25 N-m (20IN-LBF)

9. CLEAN AND DEGREASE BACKPLATE ASSEMBLY BEFORE ATTACHING INSULATION.

10. AFTER APPLICATION THE INSULATOR MUST BE FREE OF BUBBLES, POCKETS, CREASES, AND

ANY OTHER DEFORMATIONS.

11. FINAL ASSEMBLY SHALL BE FREE OF OIL AND DEBRIS.

12 PRESS FIT BOLSTER-LEC GUIDE PIN (H78231) INTO BOLSTER PLATE ASSEMBLY. MUST HAVE PIN FLUSH

WITH BOLSTER FLANGE.

13 POST SEPARATION FORCE (INDIVIDUAL):

- PUSHOUT FORCE > 89N (20LBF)

- FAILURE MODES: MUST NOT SHEAR, DEFORM, STRIP, OR CRACK BELOW FORCE LIMIT.

14 BACKPLATE ASSEMBLY (H77469) TO BOLSTER PLATE ASSEMBLY STUD/NUT MUST BE ABLE TO

ENGAGE WITH MOTHERBOARD THICKNESS' IN THE RANGE OF 1.42MM-2.59MM (0.056"-0.102").

15 FLATNESS MUST BE MEASURED IN THE UNCONSTRAINED STATE. ALL OTHER CTF MEASUREMENTS

CAN BE MEASURED IN A CONSTRAINED STATE.

16 WHEN INSTALLING BOLSTER PLATE TO BACKPLATE (H77469) THERE MUST BE NO THREAD SHAVINGS WHEN

ASSEMBLING 2 CYCLES IN ANY SEQUENCE, OR 6 CYCLES WHEN SEQUENCING IS IMPLEMENTED. SEQUENCING

SHOWN ON PAGE 2. NO DEBRIS (ANYTHING GREATER THAN 0.5MM DIAMETER OR LENGTH) IS MEASURED WITH

NAKED EYE AT 2 FEET AWAY, WITH DIRECT OVERHEAD LIGHTING UNDER COOL WHITE FLOURESCENT LIGHT

CONDITIONS (60-120 FT-CANDLES (645-1293 LUX) OR EQUIVALENT). VIEWING TIME SHALL BE ONE VISUAL

PASS OF 5-7 SECONDS FOR EACH SURFACE.

17 SEE PRE-CONDITIONING REQUIREMENT DETAILS ON PAGE 2 ZONE B-3.

7X

2X

2X

4X

10

3X

1

3

7

8

9

2

5

4

6

C

C

C

C

C

PARTS LIST

DESCRIPTIONPART NUMBER

ITEM NO

QTY

KNL BOLSTER PLATE ASSEMBLYH77470-008TOP

KNL BOLSTER CORNER STANDOFFH77926-00512

KNL BOLSTER LARGE GUIDE POSTG94443-00321

KNL BOLSTER LEC GUIDE PINH78231-00432

KNL BOLSTER PLATEG93727-00541

KNL BOLSTER PLATE INSULATORG93729-00251

KNL BOLSTER SMALL GUIDE POSTG93935-00361

KNL SPRING ASSEMBLYH37308-00972

SKT-P-KNL, SPRING RIVETH19325-00184

SOCKET P M3 BOLSTER CAPTIVE NUTH19328-00297

SOCKET P M3 BOLSTER CAPTIVE NUT COLLARH19329-003103

Loading...

Loading...