6700SR Refrigerated Sampler

44

How Does the Sampler Work?

When the sampler takes a sample, it draws liquid through the

strainer and suction line to the pump tube. The liquid flows

through the pump tube, past the liquid detector, which senses the

liquid. From the detector, the liquid follows the pump tube through

the pump to the bulkhead fitting and then through the discharge

tube to the sample bottle.

A typical sampling cycle consists of:

1. The sampler moves the distributor arm over the bottle that

is to receive the sample.

2. The pump reverses for the presample purge.

3. The pump direction changes, filling the suction line.

4. When the detector senses liquid, the sampler begins measur-

ing the sample. (See Measuring Sample Volume on page 45.)

5. After depositing the sample, the pump again reverses for the

postsample purge.

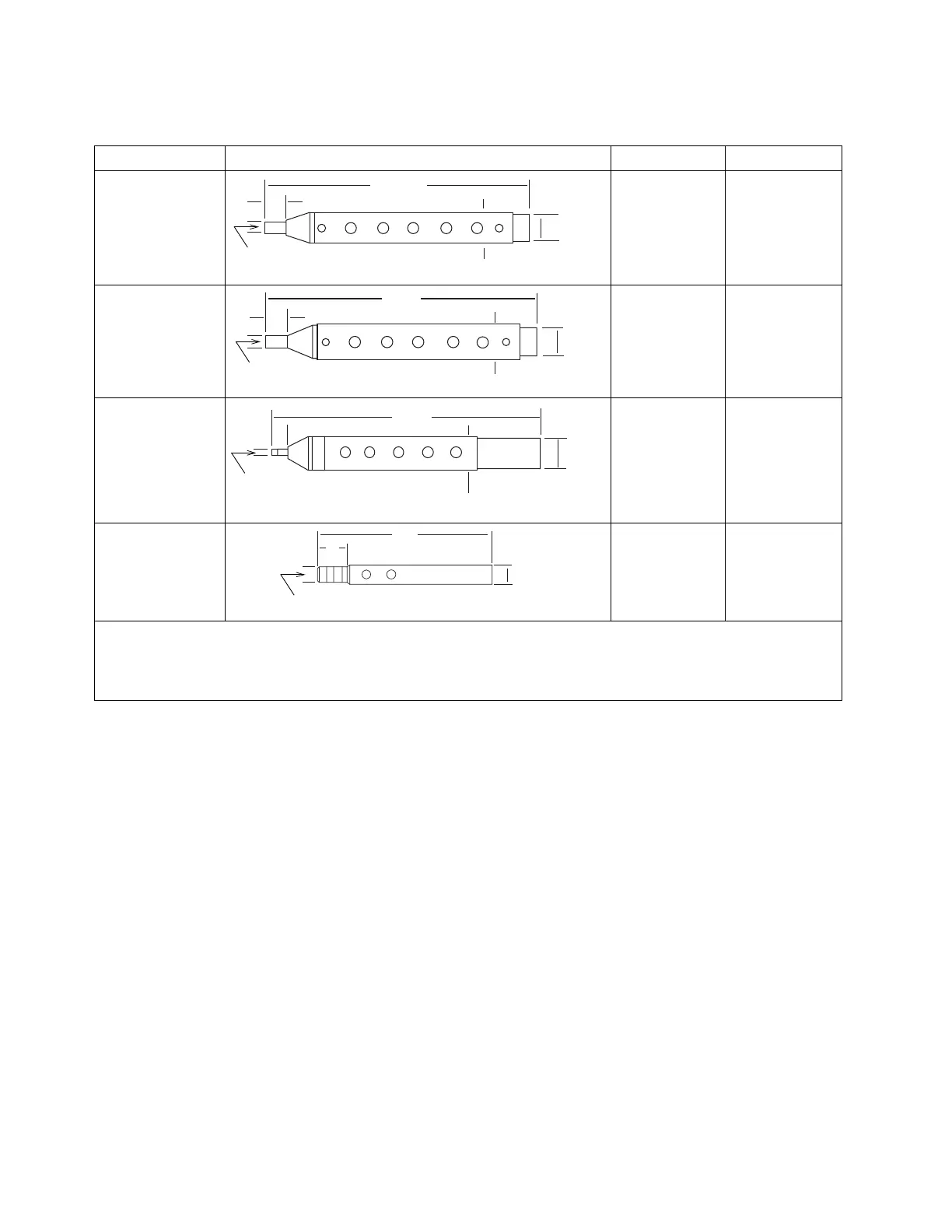

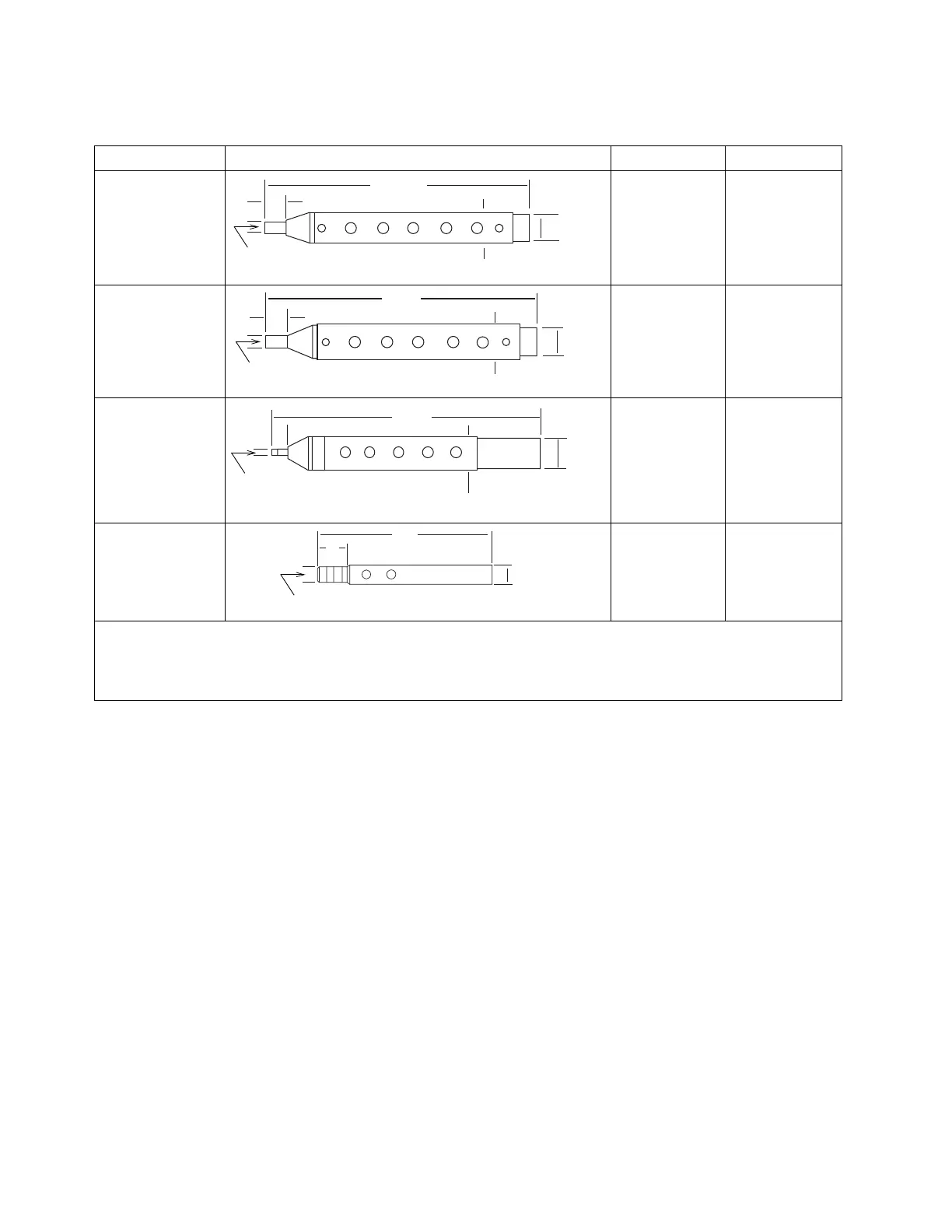

S

TRAINER

D

IMENSIONS

A

PPLICATION

M

AXIMUM

D

EPTH

Stainless Steel

Priority-

pollutant

sampling.

Vinyl Line:

22 feet.

Teflon Line:

15 feet.

Polypropylene

Routine

applications.

Vinyl Line:

11 feet.

CPVC

Highly acidic

liquids.

Vinyl Line:

4 feet.

Stainless Steel

Low-Flow

Very low flow

stream depths.

Vinyl Line:

7 feet.

Notes: • The suction lines will float when filled with air during the purge cycles and when depths exceed the listed

ratings. Secure the suction lines when sampling at depths exceeding the maximum ratings.

• All strainer dimensions are in inches.

• Teflon suction line is compatible only with the 1 inch diameter, stainless steel strainer.

Table 7 Selecting the Right Strainer

9-9/32

23/32

1.0

diameter

1-1/8

diameter

.430

diameter

9-5/8

23/32

1.0

diameter

1-1/4

diameter

.430

diameter

11-1/4

1-5/8

diameter

1-1/4

diameter

23/32

.430

diameter

9/16

diameter

7

1

.430

diameter

Loading...

Loading...