6700SR Refrigerated Sampler

45

Sampling cycles vary somewhat according to program settings for

distribution. The sampler can move the distributor arm clockwise

and counterclockwise, making a number of distribution methods

possible. (In this manual, the words “sample event” refer to a full

sampling cycle for any distribution.)

Other variations include extended-program settings for suction

line rinses and sampling retries. A sampler running a program

with line rinses completes the presample purge and then rinses the

line. The suction line is purged after each rinse. When programmed

for sampling retries, the sampler will attempt to pump a sample

again if it fails on previous attempts.

Measuring Sample Volume

“Sample volume” refers to the amount of liquid delivered into a bot-

tle. The volume is determined by the programmed value. The vol-

ume is dependent on the volume per revolution of the pump, which

is dependent on the suction head. The 6700SR delivers the sample

by counting the pump revolutions and automatically compensating

for the suction head.

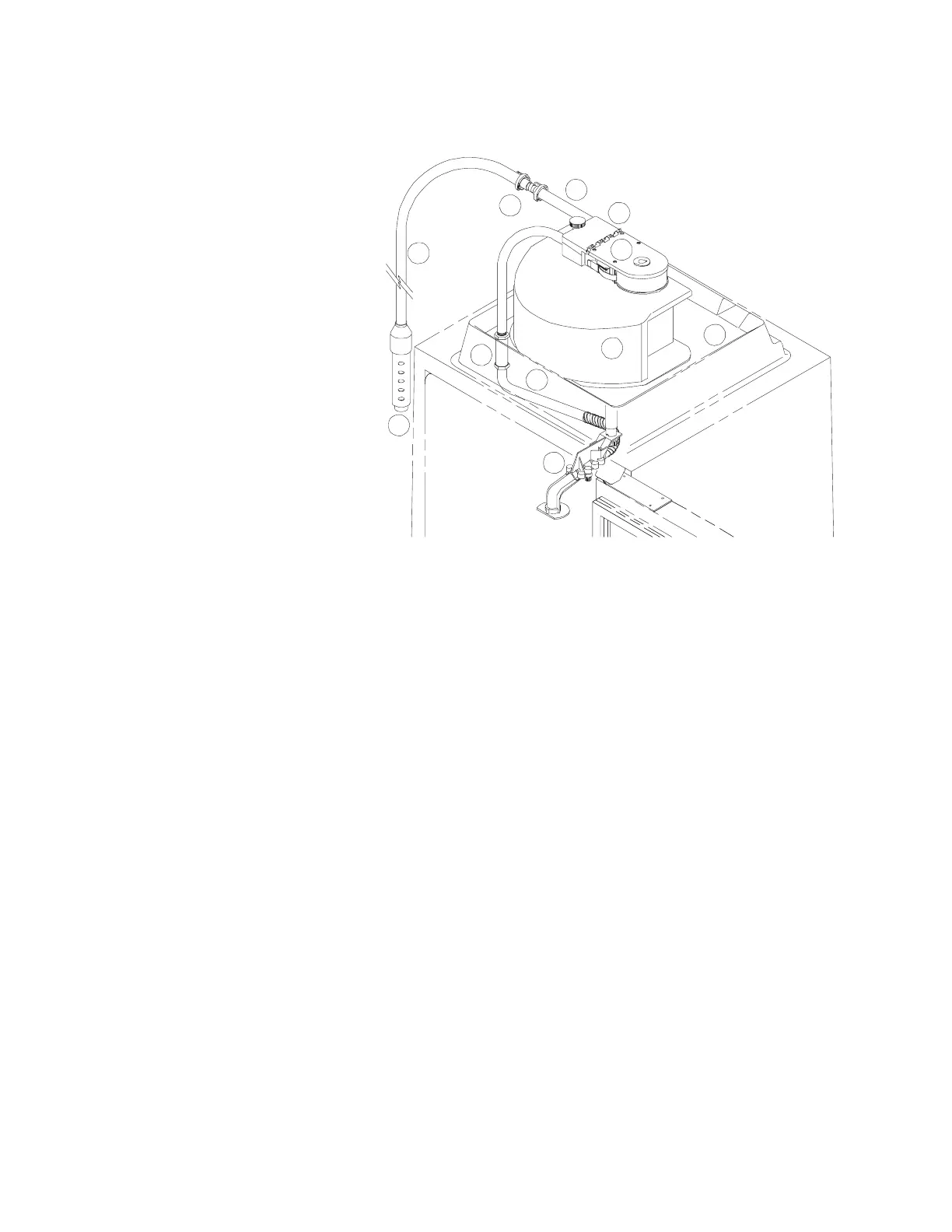

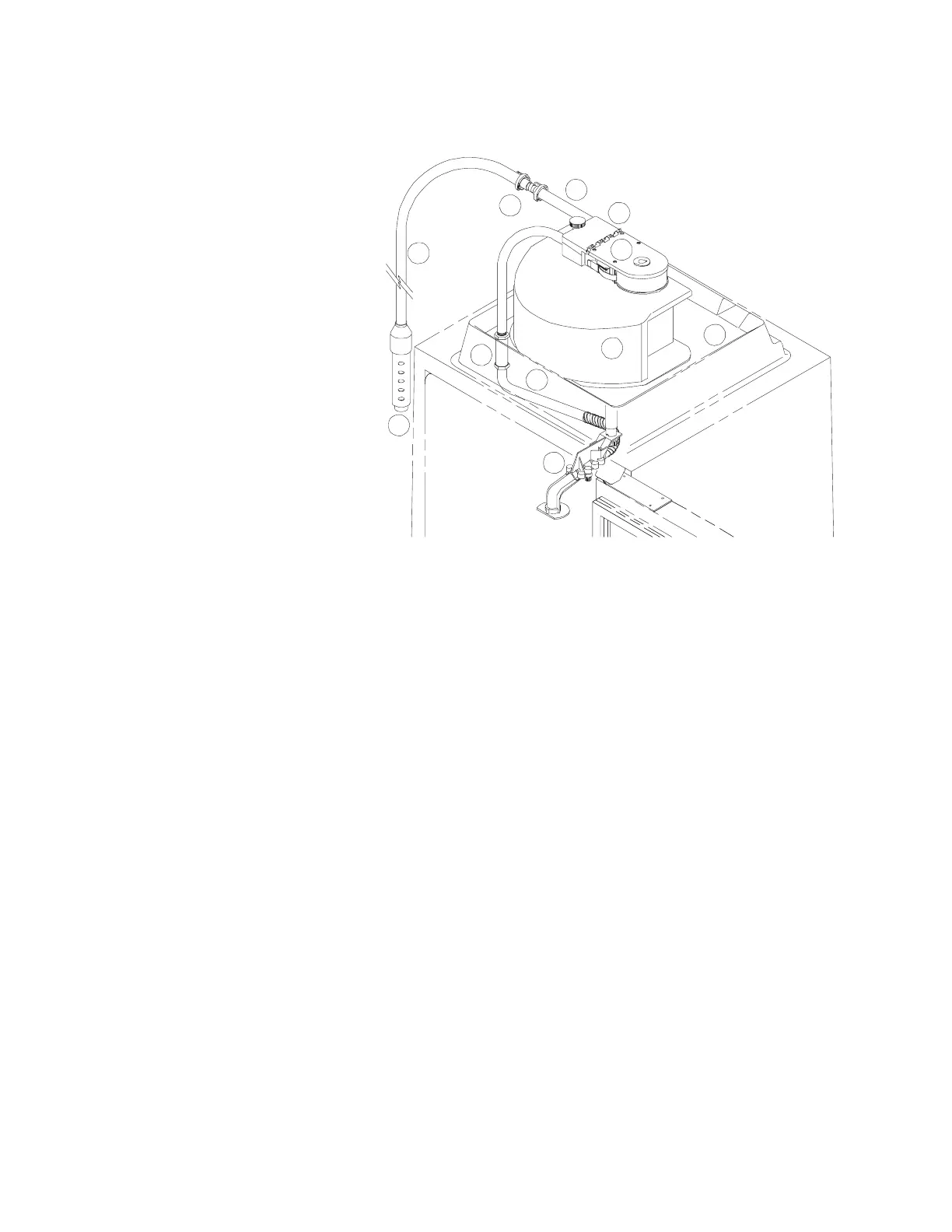

Figure 6 Identifying the Sampler Components

a. Controller

b. Refrigerator

c. Peristaltic pump

d. Liquid Detector

e. Strainer

f. Suction line

g. Coupling

h. A pump tube routed from the liquid

detector’s intake port through the

pump, out the detector’s discharge

port and over the side of the control-

ler to a bulkhead fitting at the top of

the refrigerator.

i. Bulkhead fitting

j. Discharge tube running from the

bulkhead fitting on the inside of the

refrigerator through the spring and

distributor arm

k. Distributor arm and spring

k

e

j

i

a

c

d

h

g

f

b

Loading...

Loading...