106

SERVICE MANUAL FOR SGR19 & SGR17

Fig. 9-17

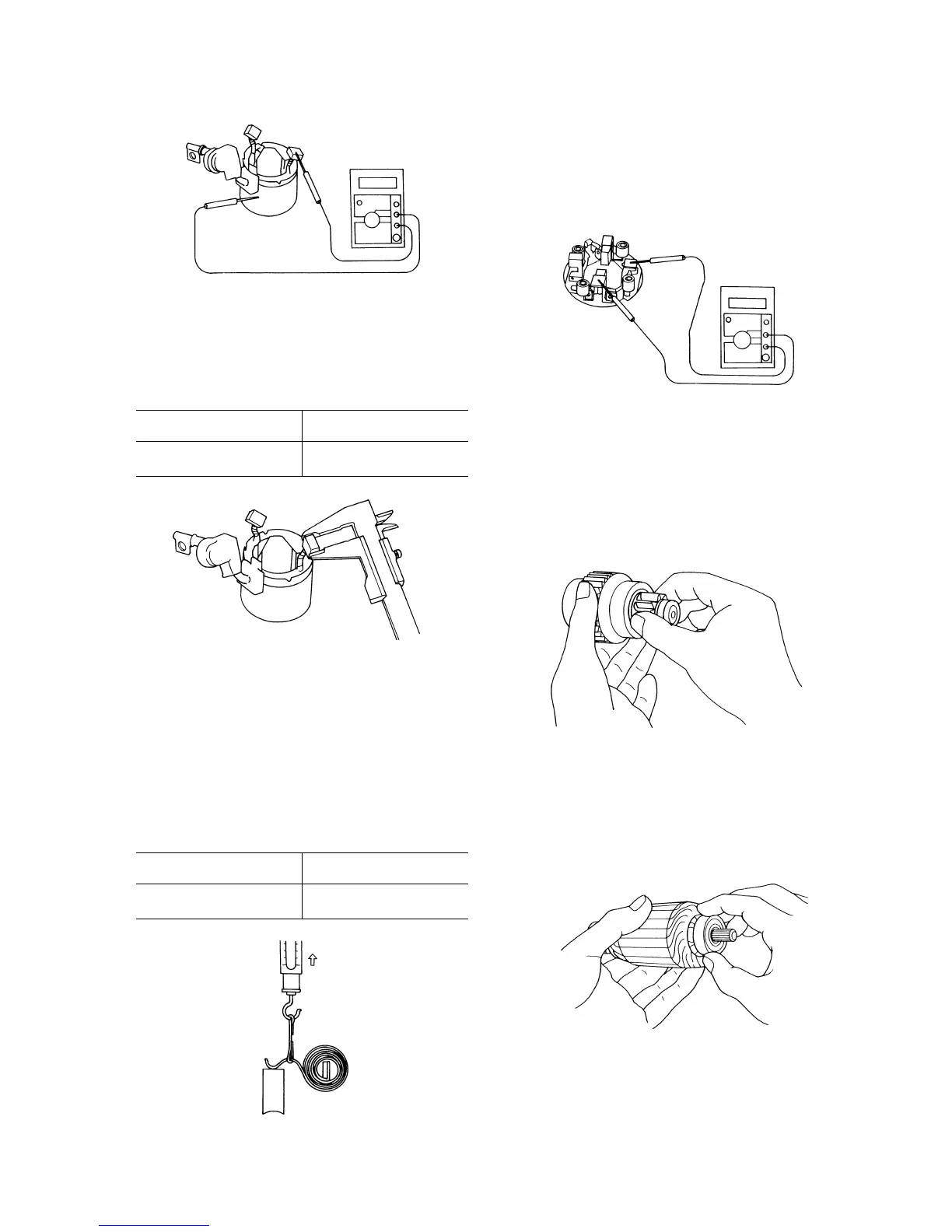

6) Inspection of the brushes

• Measure brush length in the middle.

Standard value Usable limit

15.0 mm 10.0 mm

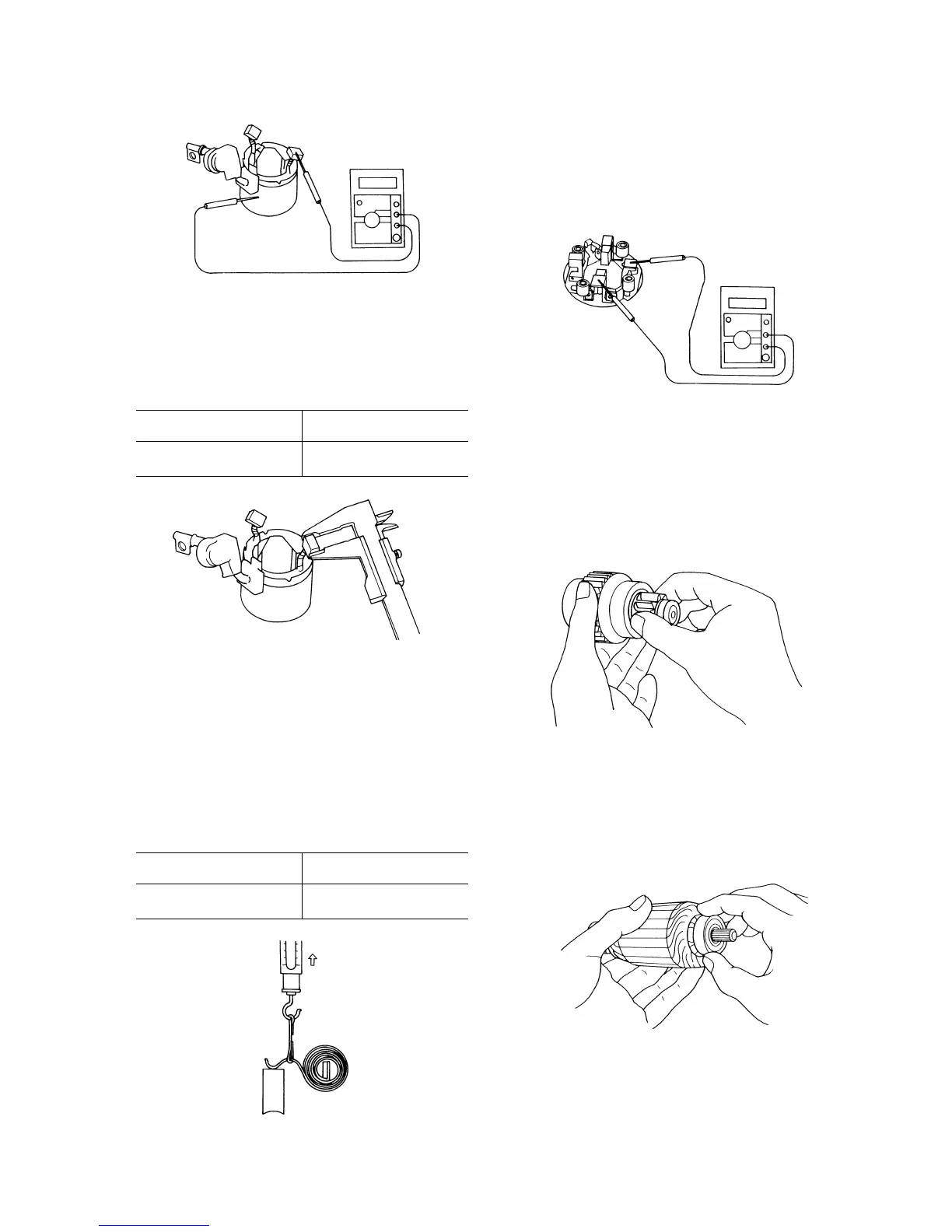

8) Inspection of the brush holder

• Inspect for insulation across positive (+) side and

negative (-) side of the brush holder. If there is

no continuity, the brush holder is normal.

Fig. 9-18

• Correct the contact surfaces of the brushes on

the sandpaper wrapped around the commutator.

7) Inspection of brush spring tension

• Measure spring tension with a spring balance and

read the balance at the moment when the spring

is about to leave the brush.

Standard value Usable limit

1785 - 2415 gr 1200 gr

Fig. 9-19

Fig. 9-20

9) Inspection of the clutch

• Inspect the gear for wear and damage.

• Make sure that the gear locks when turned in

diving direction and turns smoothly in the re-

verse direction.

Fig. 9-21

• There should be no hitching when the bearing is

turned manually by applying some force to it

with fingers.

• It should not make abnormal noises when turned

abruptly.

Fig. 9-22

11) Replacement of the bearing

• Remove the bearing or install it as illustrated.

Loading...

Loading...