44

SERVICE MANUAL FOR SGR19 & SGR17

Fig. 3-81

Measure the gaps of each piston ring with thick-

ness gauges.

Fig. 3-82

Replace the rings whose gaps are in excess of

the usable limit.

Standard value Usable limit

No.1

compression 0.25 – 0.40 mm 1.5 mm

ring

No.2

compression 0.25 – 0.40 mm 1.5 mm

ring

Oil ring 0.25 – 0.40 mm 1.0 mm

• Inspection of piston ring clearance in ring

grooves

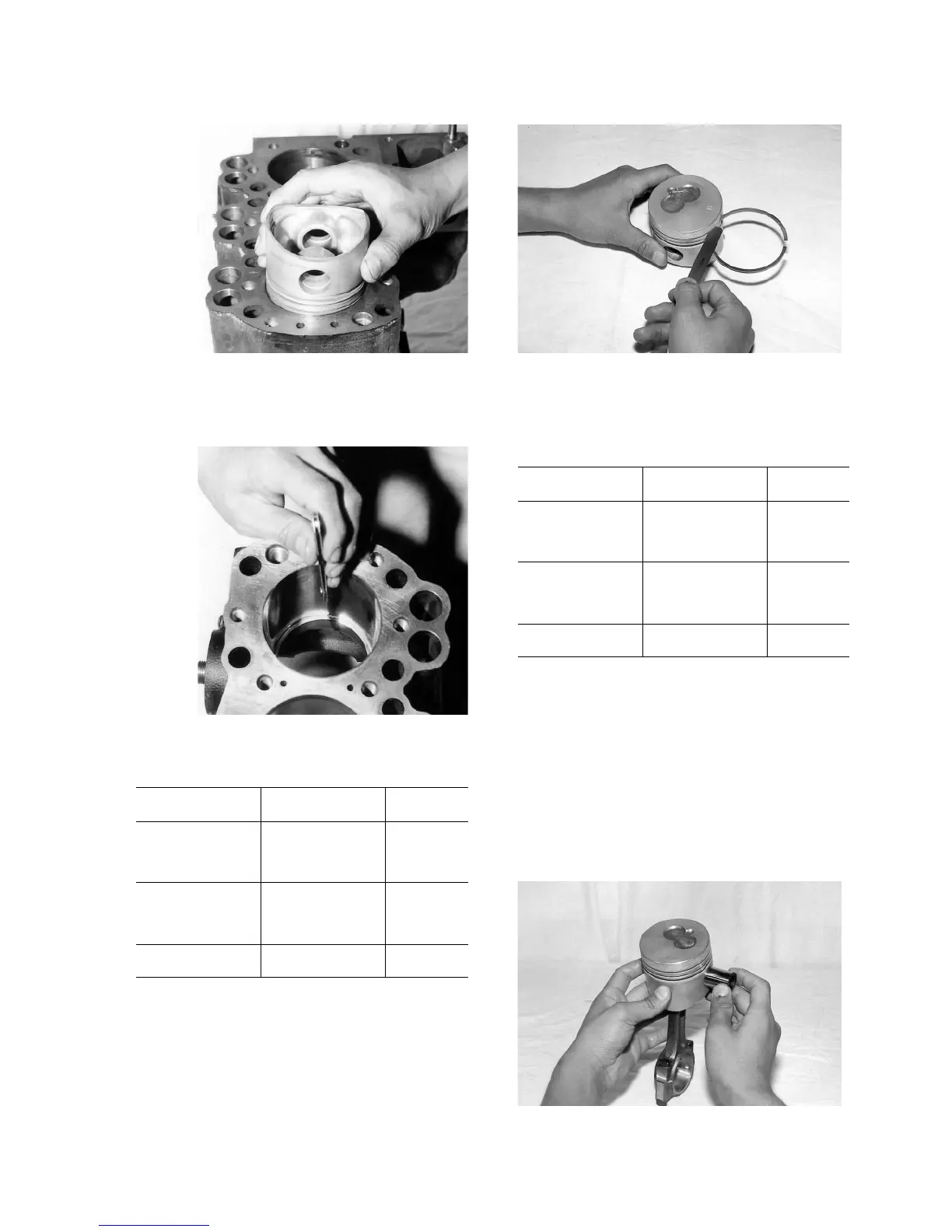

Fig. 3-83

Clean ring grooves using a used piston ring.

Measure the clearance at the outer circumference

with thickness gauges as shown in the figure.

Standard value Usable limit

No.1

compression 0.25 – 0.40 1.5

ring

No.2

compression 0.25 – 0.40 1.5

ring

Oil ring 0.25 – 0.40 1.0

When the clearance exceeds the usable limit,

replace both piston and rings as an assembly.

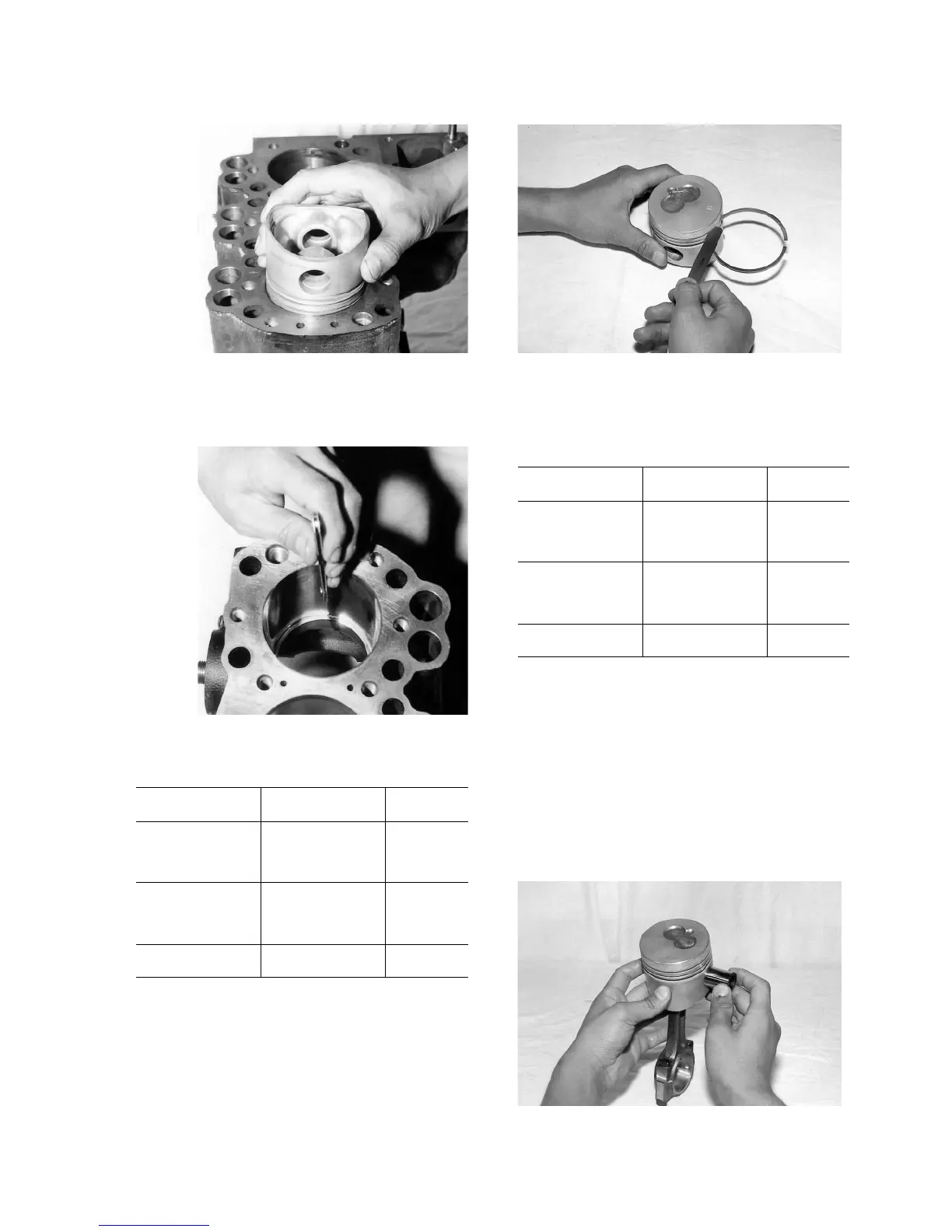

• Inspection of the piston pin

The interference between the piston pin and pis-

ton pin hole should be such that the pin can be

pushed in smoothly at room temperature.

Fig. 3-84

Loading...

Loading...