JOHNSON CONTROLS

186

FORM 145.05-NOM7

ISSUE DATE: 10/31/2019

SECTION 7 – PARAMETER DESCRIPTIONS AND OPTIONS

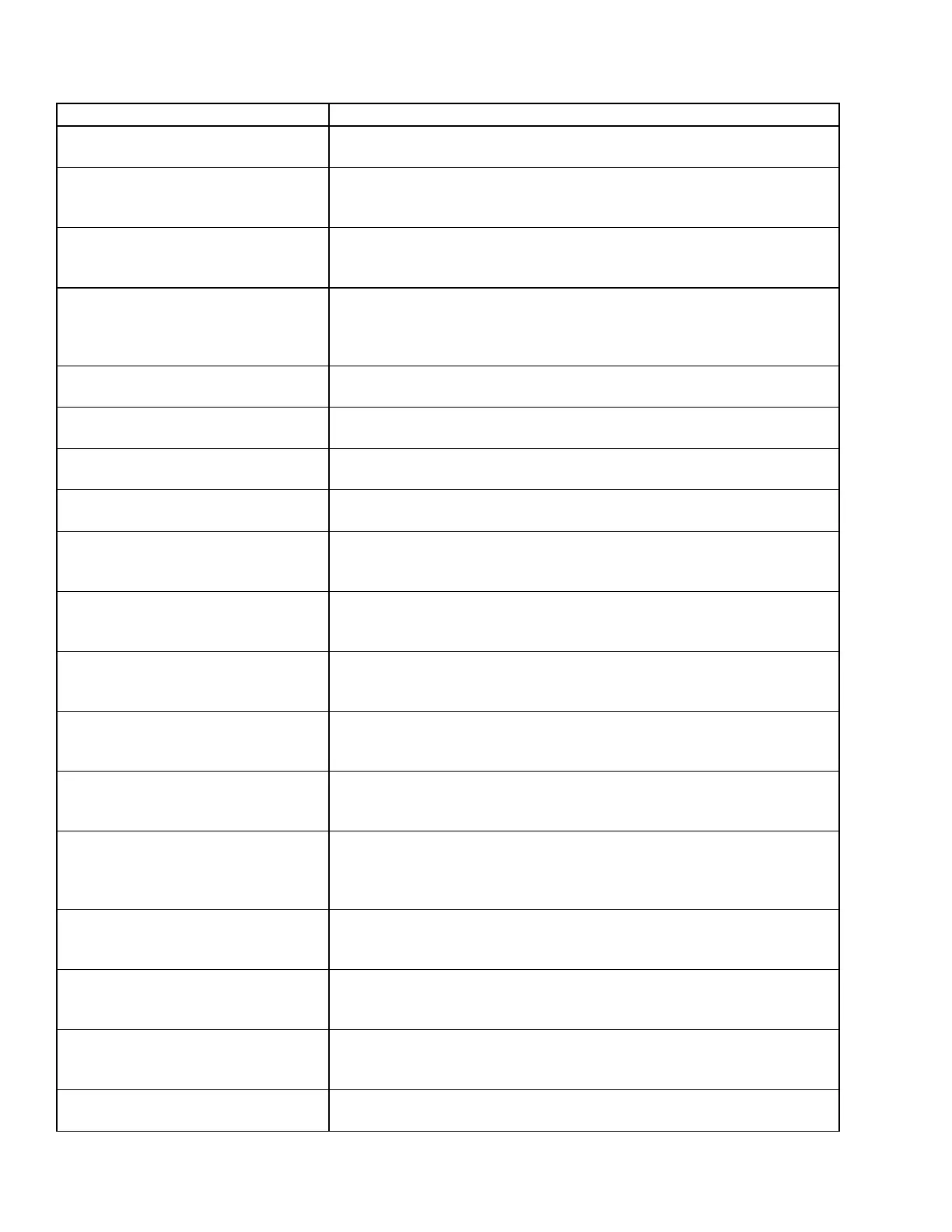

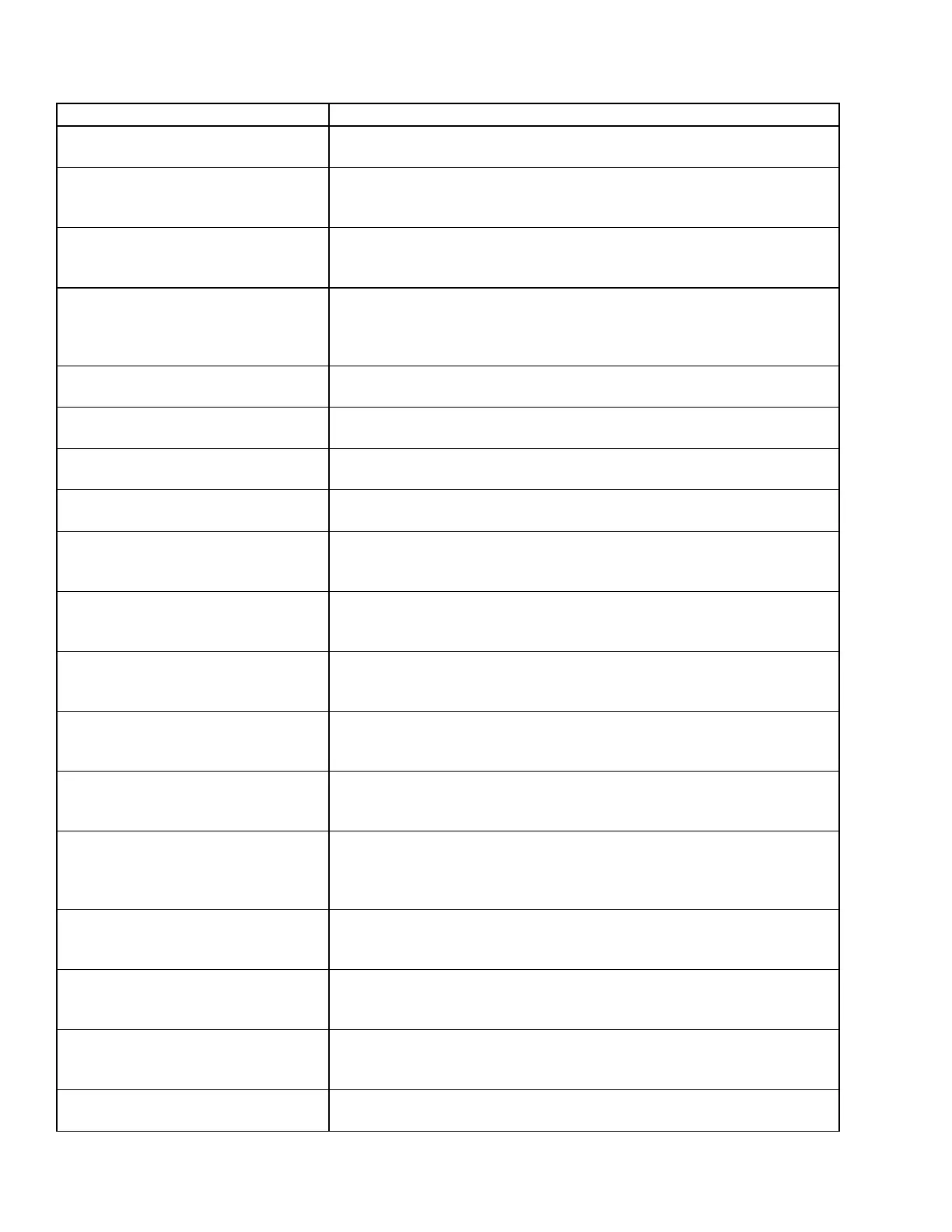

MENU ITEM DEFINITION

DATA LOG FORMAT

This parameter is set through the Service key and is used to initiate the data

logging feature. The options are Off, Uncompressed, Skip Unchanged.

DE MODIFIER ADDRESS

This parameter is programmed through the Service key. The default value is 230

which results in a DE Instance number of 23000 plus the MAC address. This is

the YORK default value. If it is set to -1 all communication is disabled.

DE MODIFIER OFFSET

This parameter is programmed through the Service key. The default value is -1.

The DE Instance number can be set manually using the DE Modier Address

and this parameter.

DEW POINT RESET

This parameter is programmed through the PROGRAM key. This function

changes the Active Supply Air Temperature to a lower value when the air be-

neath the oor of a FlexSys unit approaches the dew point temperature of the

air. The choices are Enabled or Disabled.

DIG COMP LOAD PT 1

This is the lowest capacity the digital compressor (A) can operate at. The default

value is 33%

DIG COMP LOAD PT2

This is the middle capacity the digital compressor (A) can operate at. The de-

fault value is 67%

DIG COMP LOAD PT 3

This is the maximum capacity the digital compressor (A) can operate at. The

default value is 100%

DISCHARGE PRESSURE MINIMUM

This parameter identies the lowest discharge pressure of all the active com-

pressors.

DISCHARGE PRESSURE SETPOINT

This parameter is programmed through the SETPOINTS key and is the dis-

charge pressure the Unit Controller tries to maintain by adjusting the condenser

water ow.

DISCHARGE PRESSURE SP Min

This parameter is programmed through the SETPOINTS key and is the mini-

mum discharge pressure the unit controller tries to maintain by modulating the

condenser water ow.

DISCHARGE PRESSURE SP Max

This parameter is programmed through the SETPOINTS key and is the maxi-

mum discharge pressure the unit controller tries to maintain by modulating the

condenser water ow.

DISPLAY LANGUAGE

This parameter is programmed through the PROGRAM key. This allows the

user to select the language the Primary Unit Controller uses to display the infor-

mation at the User Interface. The choices are English or Spanish.

DISPLAY UNITS

This parameter is programmed through the PROGRAM key. This allows the user

to select which unit of measure the Primary Unit Controller uses to display the

information at the User Interface. The choices are Imperial, SI, or SI Canada.

DUCT PRESS CNTRL

This parameter is set through the PROGRAM key and is used to specify the

type of pressure control to use when the unit is programmed for two duct static

pressure transducers. The options are duct press 1 only, highest, lowest and

average.

DUCT PRESS SENSOR 2

This parameter is set through the OPTIONS key and is used to identify when

two duct static transducer have been installed. The options are Not Installed or

Installed.

DUCT PRESS TRANSDUCER SPAN

This parameter is programmed through the SETPOINTS key. This allows the

use of three different duct pressure control ranges, 0 to 1.00 IN-WG, 0 to 2.50

IN-WG, or 0 to 5.00 IN-WG.

DUCT STATIC OVER PRES

This parameter is programmed through the Setpoints key. This sets the maxi-

mum allowable Duct Static value before the Primary Unit Controller lockouts the

unit on an over pressure fault.

DUCT STATIC PRES CURRENT 1

This is the actual duct static pressure sensed by static pressure transducer 1

when the Unit Controller is programmed for two duct static inputs.

TABLE 43 - DEFINITIONS (CONT'D)

Loading...

Loading...