JOHNSON CONTROLS

185

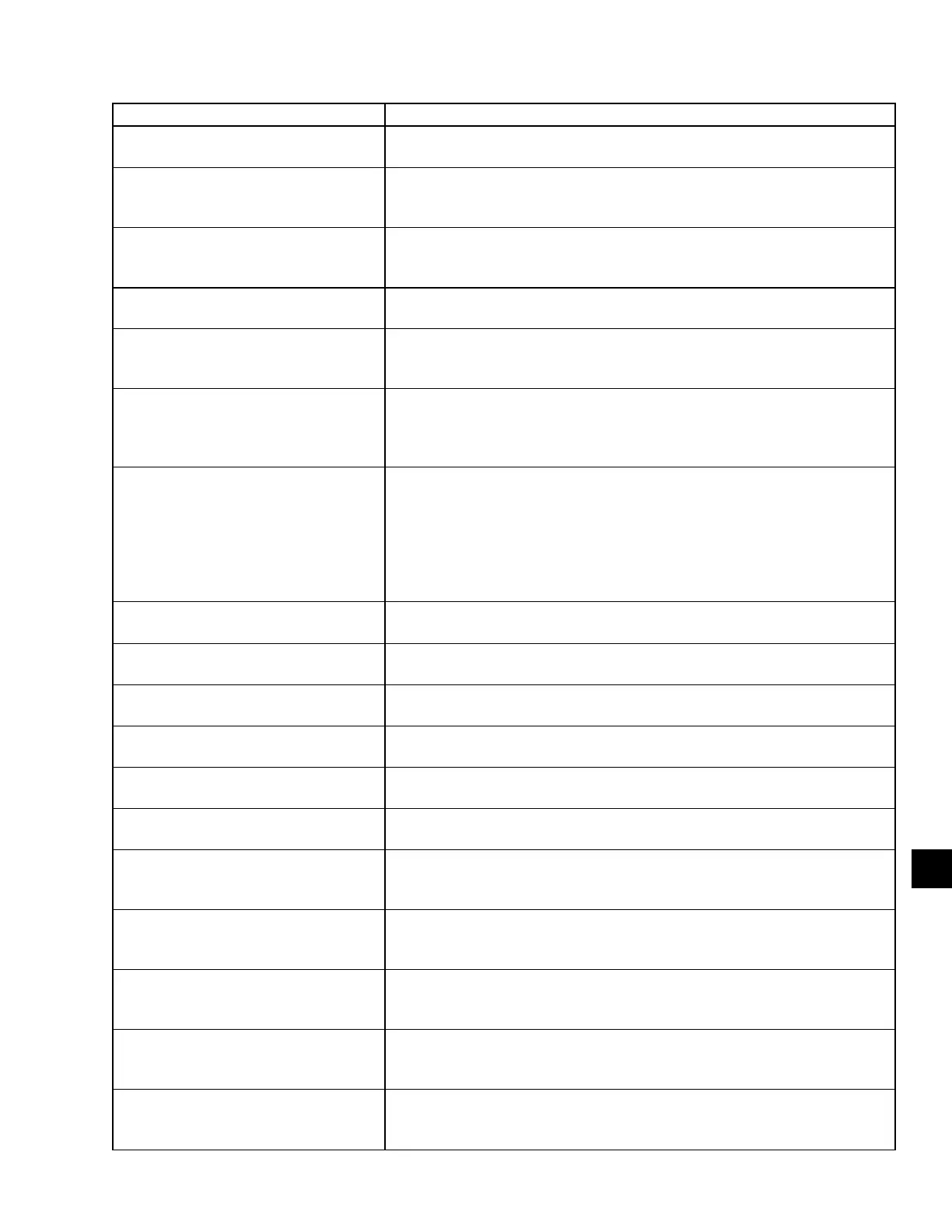

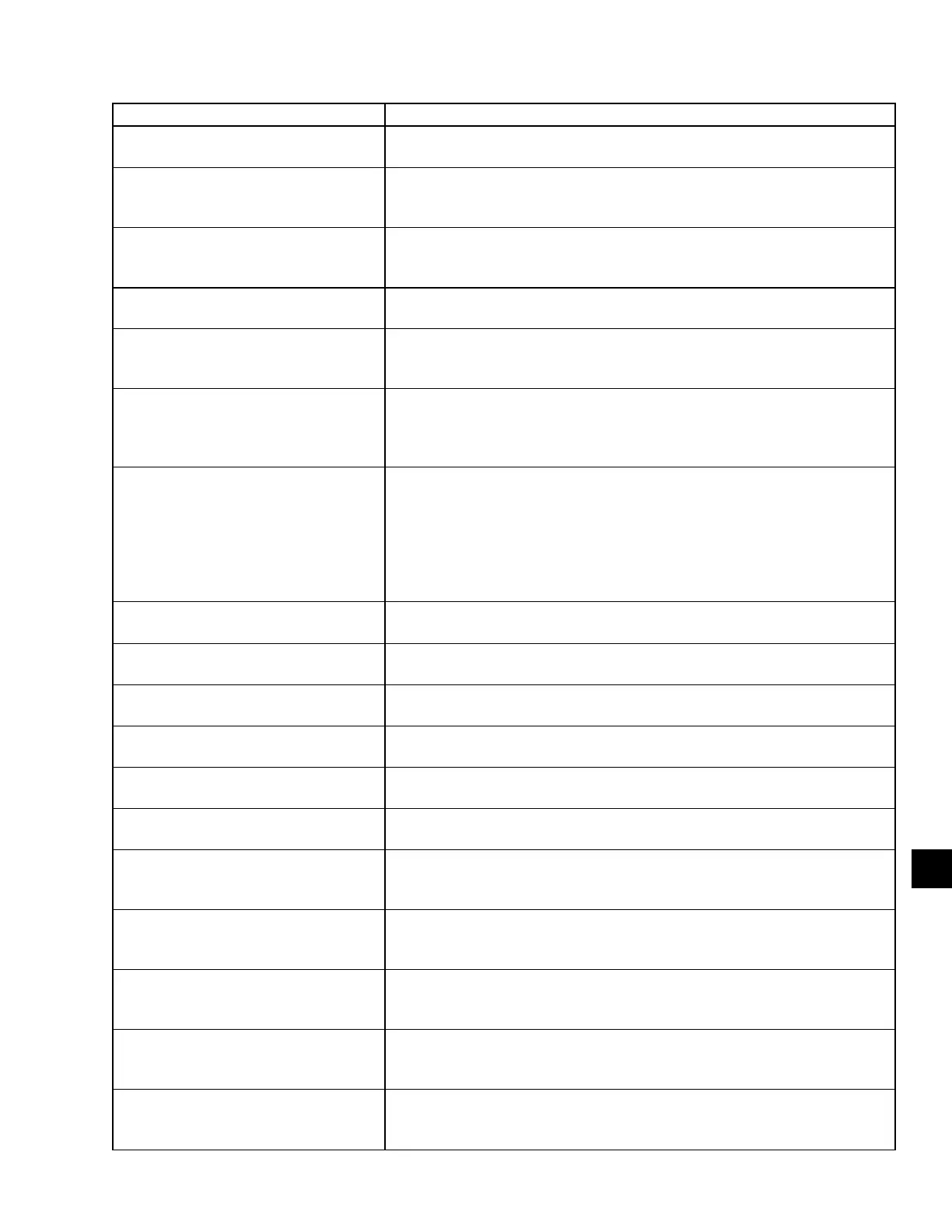

SECTION 7 – PARAMETER DESCRIPTIONS AND OPTIONS

FORM 145.05-NOM7

ISSUE DATE: 10/31/2019

7

MENU ITEM DEFINITION

COND WATER VALVE

This is the analog output from the Unit Controller to the condenser water control

valve.

CONDENSER PRESSURE PI OUTPUT

This parameter is the demand generated by the Unit Controller from the com-

parison of the lowest compressor discharge pressure to the Discharge Pressure

Setpoint.

CONDENSER TYPE

This parameter is programmed through the OPTIONS key and is used to identify

the type of condenser being used by the unit. The options are Water Cooled or

Air Cooled.

CONDENSER WATER FLOW

This parameter identies if the binary input from the condenser water ow switch

is on open or closed. The options are ON - ow and OFF - no ow.

CONTROL METHOD

This parameter is programmed through the PROGRAM key and identies the

control method being used on a Constant Volume unit. The choices are Wired

Zoned Temp or Comm Zone Temp.

COOLING CONTROL OFFSET

This is a derived value and is the control band the unit is trying to maintain. The

control band is the Active Setpoint plus or minus the Cooling Control Offset. If

the temperature is above this band additional cooling is required, if the tempera-

ture is below this band cooling is decreased.

CURRENT OPER MODE

This is the current operating mode of the unit. The display shows OCC Standby,

OCC Cooling Low, OCC Cooling High, OCC Heating Low, OCC Heating High,

UNOCC Standby, Unocc Cooling Low, UNOCC Cooling High, UNOCC Heating

Low, UNOCC Heating High, Morning Warm-up, Comfort Vent Cooling, Com-

fort Vent Heating, Occupied Cooling, Occupied Heating, Unoccupied Cooling,

Unoccupied Heating, OCC Cooling W/O Bypass, OCC Cooling W/Bypass, or

Underoor Temp Override.

CURRENT RUN TIME COMP A

This is a derived value and is the amount of time the compressor A has been in

operation during the current cycle.

CURRENT RUN TIME COMP B

This is a derived value and is the amount of time the compressor B has been in

operation during the current cycle.

CURRENT RUN TIME COMP C

This is a derived value and is the amount of time the compressor C has been in

operation during the current cycle.

CURRENT RUN TIME COMP D

This is a derived value and is the amount of time the compressor D has been in

operation during the current cycle.

CURRENT RUN TIME COMP E

This is a derived value and is the amount of time the compressor E has been in

operation during the current cycle.

CURRENT RUN TIME COMP F

This is a derived value and is the amount of time the compressor F has been in

operation during the current cycle.

DAILY WARM UP TIME DAY 1

This is a derived value and is the Morning Warm Up time the Primary Unit Con-

troller recorded during the previous day 1. This value is used to calculate the

current Morning Warm initiate time for Adaptive Morning Warm Up.

DAILY WARM UP TIME DAY 2

This is a derived value and is the Morning Warm Up time the Primary Unit Con-

troller recorded during the previous day 2. This value is used to calculate the

current Morning Warm initiate time for Adaptive Morning Warm Up.

DAILY WARM UP TIME DAY 3

This is a derived value and is the Morning Warm Up time the Primary Unit Con-

troller recorded during the previous day 3. This value is used to calculate the

current Morning Warm initiate time for Adaptive Morning Warm Up.

DAILY WARM UP TIMER

This is a derived value and is the time it takes to bring the return air temperature

up to setpoint during Adaptive Morning Warm Up. The Primary Unit Controller

uses this value in the calculation of Daily Warm Up Time Day 1.

DAMPER HARDWARE

This parameter is programmed through the Options key and identies the type

of ventilation system installed in the unit. The choices are None, 2 Position

Damper, Standard Dampers.

TABLE 43 - DEFINITIONS (CONT'D)

Loading...

Loading...