Section 3 Installation

33

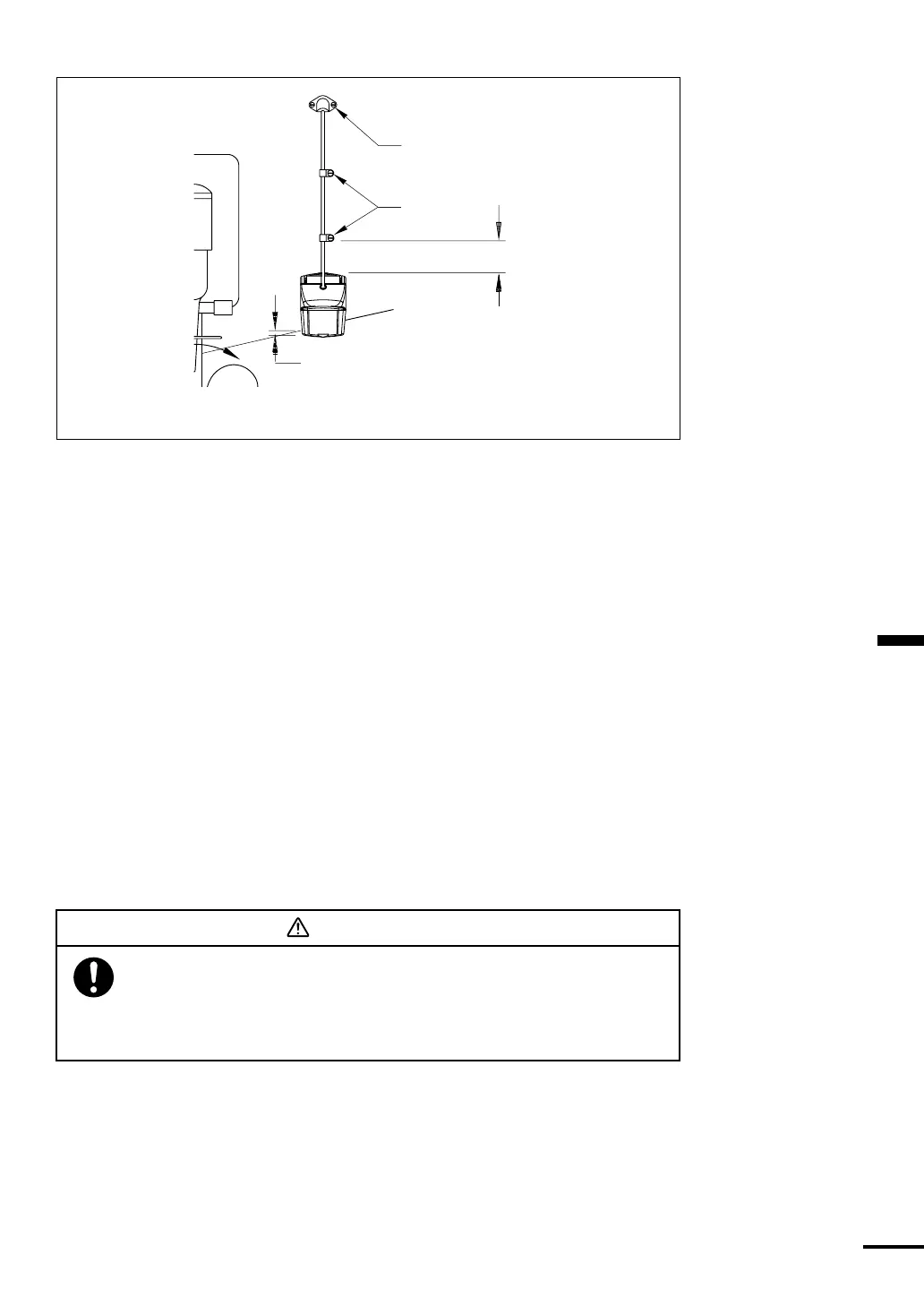

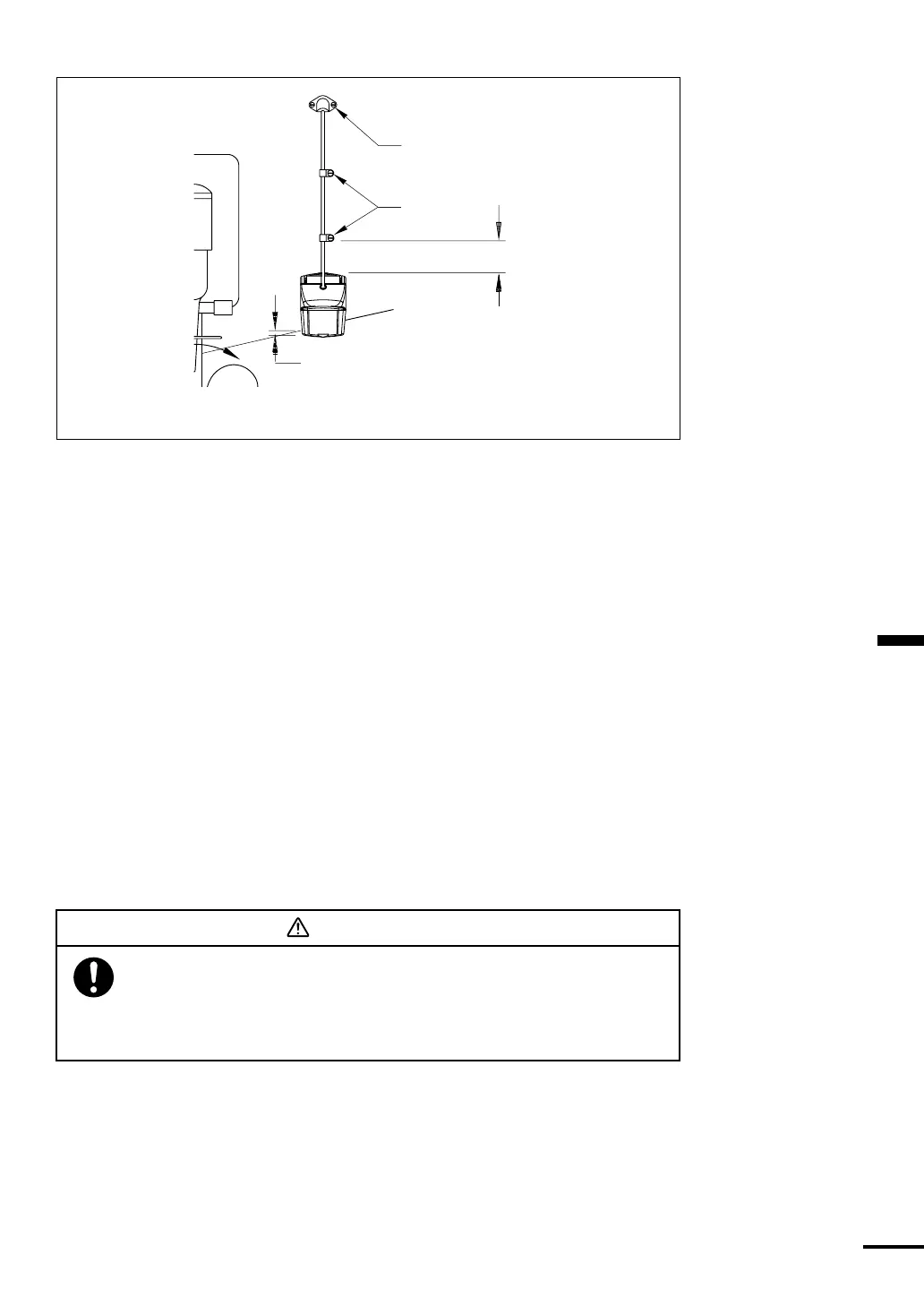

Ver tical adjustment and cable routing

2"(50mm )

cable cover

cable clamp

Hull projection

1/8" (3mm)

Figure 3-9

Testing on the Water

➀

Become familiar with your echosounder’s performance at a speed of 4kn

(5MPH).

➁

Gradually increase the boat speed and observe the gradual decline in

performance due to turbulent water flowing over the transducer’s active

surface.

➂ If the degradation is sudden (not gradual), identify the boat speed at which

the onset occurred. Return the boat to this speed, then gradually increase

speed while making moderate turns in both directions.

➃

If the performance improves while turuing, the sensor’s position probably

needs adjustment, because it is in aerated water. Move the sensor farther

down into the water in increments of 1/8" (3mm). If the performance does

not improve satisfactorily, move the sensor closer to the centerline of the

boat. Fill unused screw holes with marine sealant.

High speed operation - May require less projection in the water.

Checking for Leaks

When the boat is placed in the water, immediately

check for leaks around the screws and any holes

drilled in the hull. Never install a sensor and leave

the boat in the water unchecked for several days.

WARNING

Antifouling Paint

Marine growth can accumulate rapidly on the sensor’s surface reducing

performance in weeks. Surfaces exposed to salt water that do not interlock, must

be coated with antifouling paint. Use water-based antifouling paint only. Never

use ketone-based paint, since ketones can attack many types of plastic possibly

causing damage to the transducer. Apply paint every 6 months or at the

beginning of each boating season.

Loading...

Loading...