– 19 –

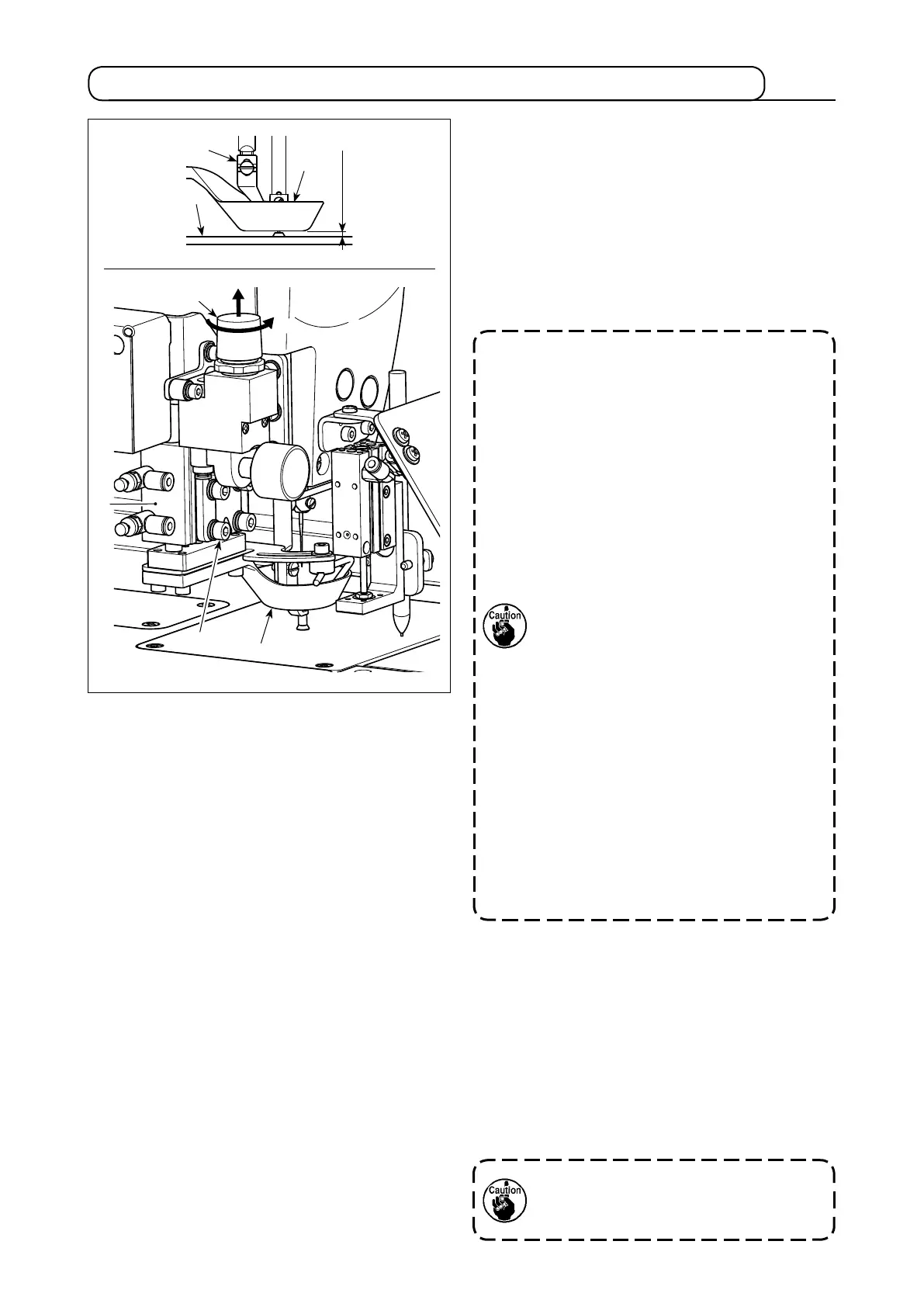

4-11. Adjusting the height of disc presser and the presser foot pressure

❷

❶

❸

3 ± 0.2 mm

❻

A

❺

❷

❹

(1) Adjusting the height of disc presser

1) Lower disc presser

❷

. In this state, loosen set-

screws

❹

(4 pieces).

2) Adjust the vertical position of air cylinder

❺

so

that the distance from the undersurface of disc

presser

❷

to the top surface of throat plate

❸

becomes 3 ± 0.2 mm. Then, tighten setscrews

❹

(4 pieces). (This distance should be adjusted ac-

cording to the thickness of template to be used.)

(2) Adjusting the disc presser pressure

Disc presser

❷

is lifted/lowered by air cylinder

❺

.

When two pieces of material are sewn with cotton or

feather stuffed between them, the pressure applied

to the material can be reduced by appropriately ad-

justing the height and pressure of disc presser

❷

.

1) Pull up pressure reducing valve

❻

. Turn the

valve in the direction of arrow

A

to reduce the

pressure applied to the material.

1. During adjustment, take care to

prevent interference between disc

presser

❷

and intermediate presser

❶

. At the same time, take care so that

the undersurface of disc presser

❷

is

in parallel to the top surface of throat

plate

❸

.

2. Aforementioned adjustment value

of the height of disc presser

❷

(3 ±

0.2 mm) is given on the assumption

that the recommended template (total

thickness of upper and lower (i.e.,

two) templates is 3 mm) is used. In the

case templates of different thickness

are used, the height of disc presser

❷

should be adjusted so that no space is

provided between disc presser

❷

and

the templates and so that the former is

not pressed against the latter.

* The height of disc presser

❷

should

be adjusted to such a height that the

thread remaining at the tip of needle

is securely clamped by disc presser

❷

at the beginning of sewing and

that the templates do not warp due to

the feed operation during sewing.

The adjustment value of air pressure

should be adjusted to 0.25 MPa or

higher.

Loading...

Loading...