– 31 –

6-3. Reverse feed stitching

6-4. Condensation stitching

6-5. Groove on the template

Reverse feed stitches may not be accurately sewn on the normal feed stitches due to lateral vibration of the

template during sewing.

* In the case a template which has the largest longitudinal dimension (825 mm) is made, misalignment of

the normal feed and reverse feed stitches may occur in the front (near the operator) zone when the direc-

tion of sewing is lateral.

In such a case, it is recommended to select condensation stitching instead of reverse feed stitching to sew

fastening stitches.

In the case of sewing with thick thread such as Span #30, the condensation stitching pitch should be 1 mm or

more in order to prevent sewing troubles such as stitching skipping when the needle enters the same needle

entry point twice or more times and thread trimming failure.

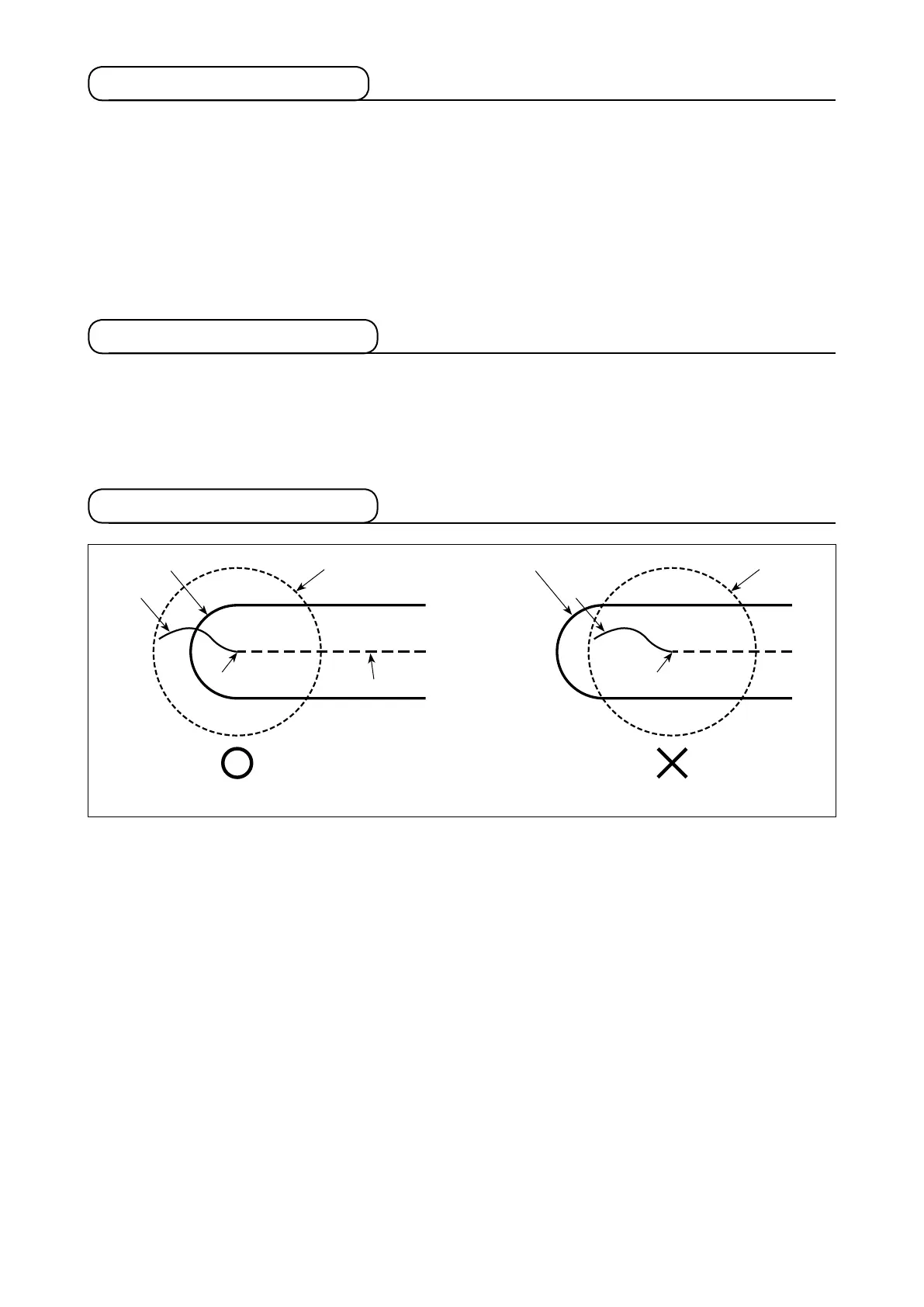

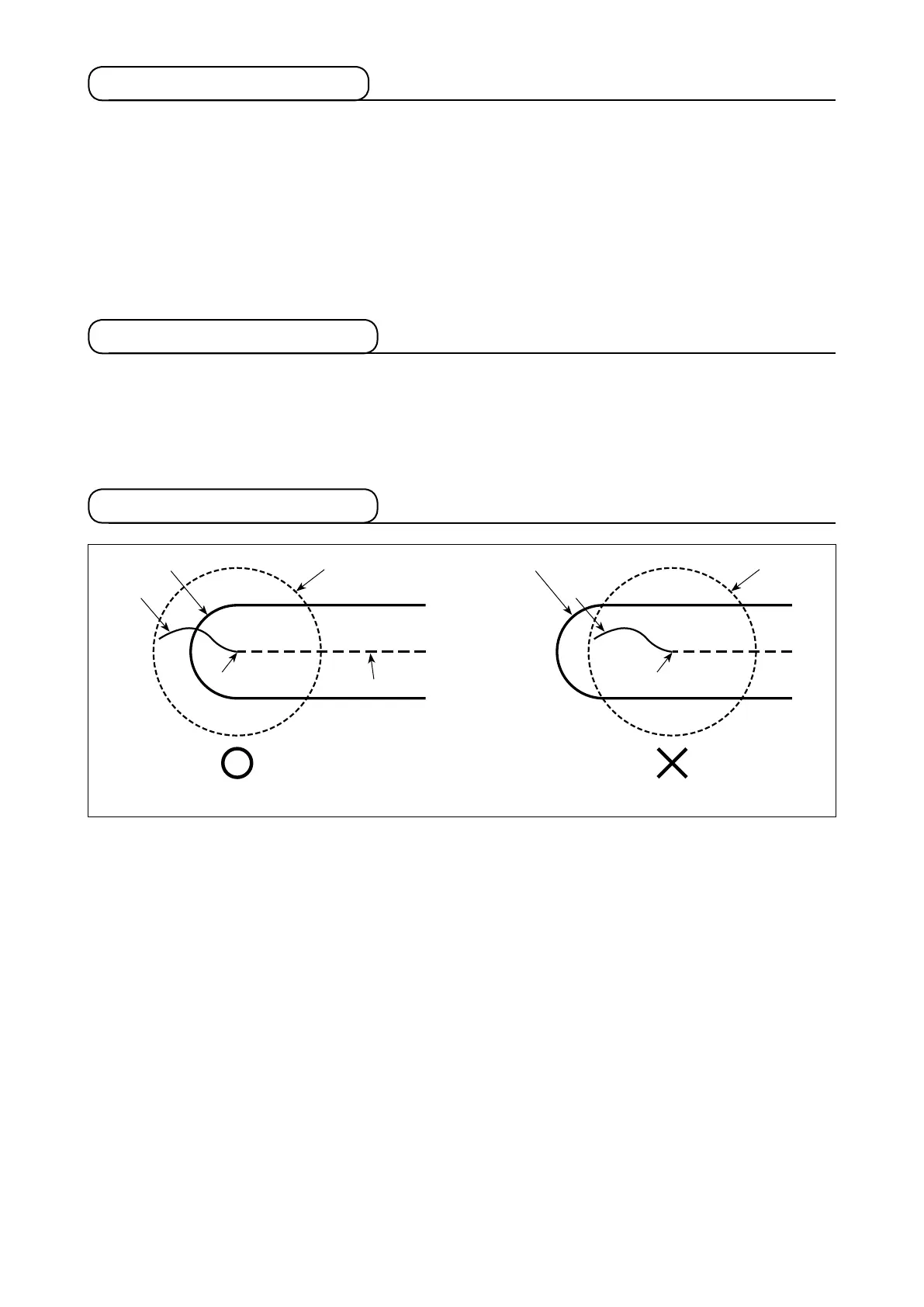

Create a stitch shape while aligning end

A

of the groove on the template with sewing starting position

B

, so

that end

C

of needle thread at the beginning of sewing can be clamped by undersurface

D

of disc presser.

If end

A

of the groove on template is moved away from sewing starting position

B

as shown in the gure on

the right, end

C

of needle thread enters the groove at the beginning of sewing and cannot be clamped by

undersurface

D

of disc presser. (Stitch skipping and thread-tangling on the reverse side of material (so-called

bird's nest phenomenon) may occur at the beginning of sewing.)

A A

C C

B B

D D

(Good) (Bad)

Seam

Loading...

Loading...