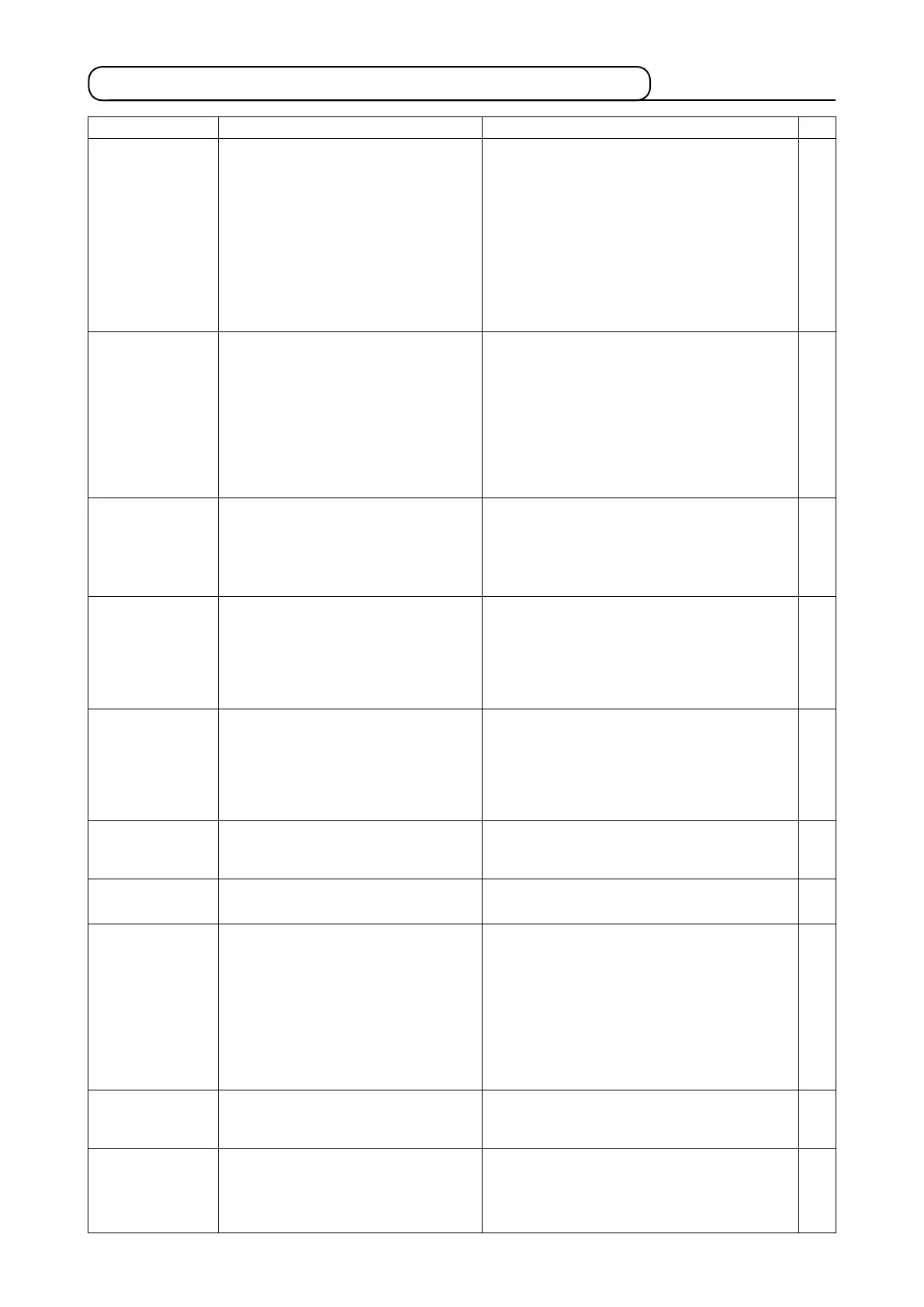

– 29 –

5-7. Troubles and corrective measures (Sewing conditions)

Trouble Cause Corrective measures Page

1. The needle thread

slips off at the start

of bar-tacking.

①

Stitches are slipped at the start.

②

The needle thread remaining on the nee-

dle after thread trimming is too short.

③

The bobbin thread is too short.

④

Needle thread tension at 1st stitch is too

high.

⑤

Stitching pitch at 1st stitch is too small.

◦

Adjust the clearance between the needle and the

shuttle to 0.01 to 0.05 mm.

◦

Set soft-start sewing at the beginning of sewing.

◦

Decrease the tension of the thread tension control-

ler No. 1.

◦

Increase the tension of the thread take-up spring.

◦

Decrease the bobbin thread tension.

◦

Increase the clearance between the needle and

the counter knife.

◦

Decrease the needle thread tension at 1st stitch,

and extend the duration of the AT operation at the

beginning of sewing.

◦

Make the stitching pitch at 1st stitch longer.

◦

Decrease the needle thread tension at 1st stitch.

17

―

15

16

15

20

―

―

―

2. Thread often

breaks or synthetic

ber thread splits

nely.

①

The hook or the inner hook holder has

scratches.

②

The needle hole guide has scratches.

③

Thread enters the groove in the hook.

④

The needle thread tension is too high.

⑤

The tension of the thread take-up spring

is too high.

⑥

The synthetic ber thread melts due to

heat generated on the needle.

⑦

When taking up the thread, the needle tip

penetrates the thread.

◦

Remove the hook and grind hook or the inner hook

holder with a ne grind stone or buff them.

◦

Buff the needle hole guide or replace it with a new

one.

◦

Detach the hook to remove the thread.

◦

Decrease the needle thread tension.

◦

Decrease the tension of the thread take-up spring.

◦

Use the optional needle cooler.

◦

Check the rough state of needle tip.

◦

Use the ball-pointed needle.

8

―

8

15

16

32

―

13

3. The needle often

breaks.

①

The needle is bent.

②

The needle comes in contact with the

intermediate presser.

③

The needle is too thin for the material.

④

Clearance between the needle and the

hook is too small.

◦

Replace the bent needle.

◦

Adjust the position of the intermediate presser.

◦

Replace it with a thicker needle according to the

material.

◦

Adjust the clearance between the needle and the

hook.

13

―

13

17

4. Threads are not

trimmed.

(Bobbin thread

only)

①

The counter knife is dull.

②

Knife pressure of the counter knife is low.

③

The counter knife has been improperly

positioned.

④

The last stitch is skipped.

⑤

Bobbin thread tension is too low.

⑥

Flopping of cloth

◦

Replace the counter knife.

◦

Adjust the knife pressure of the counter knife.

◦

Correct the position of the counter knife.

◦

Correct the timing between the needle and the

hook.

◦

Increase the bobbin thread tension.

◦

Lower the intermediate presser height.

20

20

20

17

15

17

5. Stitch skipping

often occurs.

①

Clearance provided between the needle

and the hook is not correct.

②

Position of the inner hook holder against

the needle is not correct.

③

The needle is bent.

④

The needle thread after thread trimming

is too long.

◦

Adjust the clearance between the needle and the

hook.

◦

Adjust the position of the inner hook holder against

the needle.

◦

Replace the bent needle.

◦

Decrease the tension of the thread take-up spring.

◦

Increase the tension of the thread tension control-

ler No. 1.

17

20

13

16

15

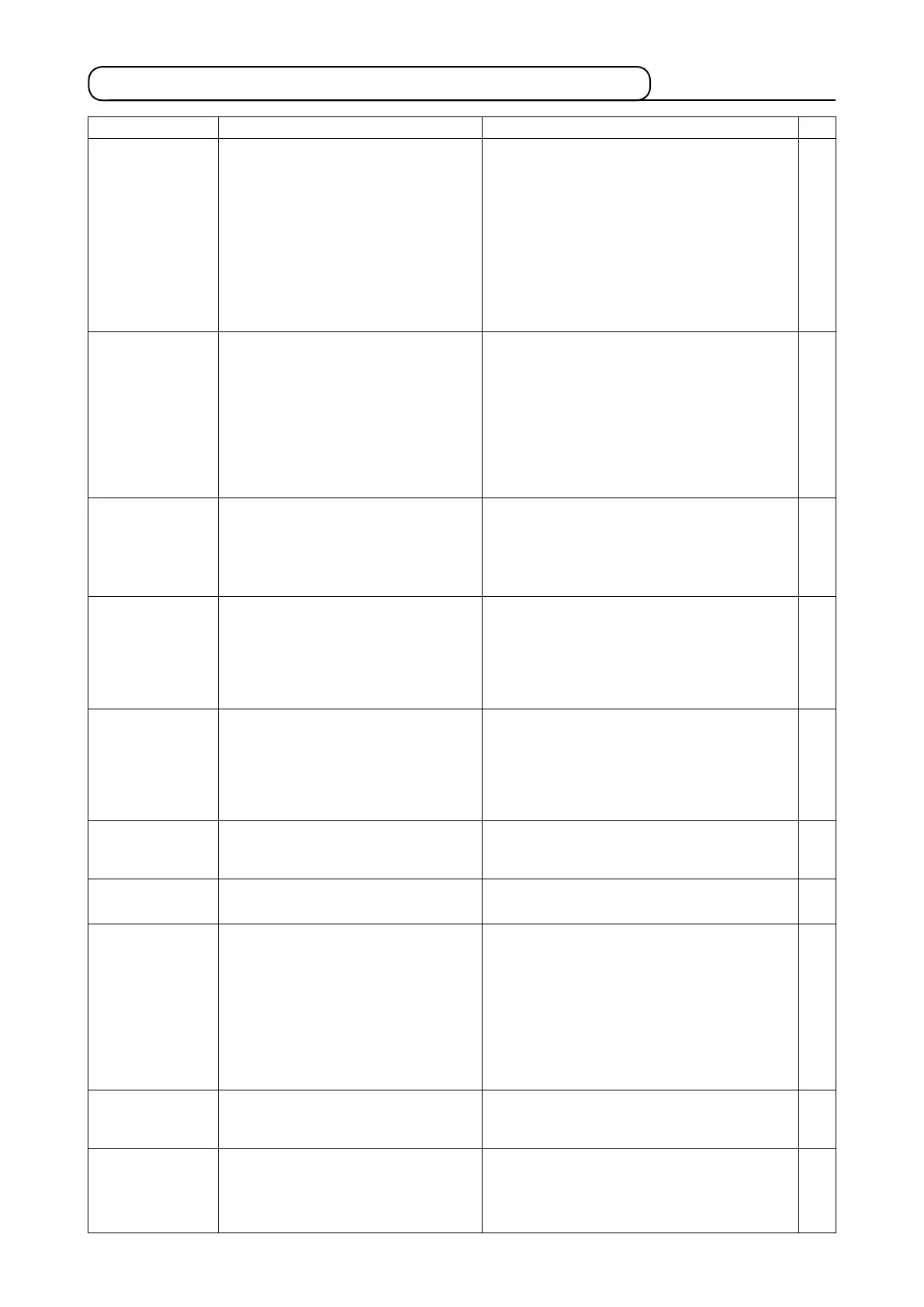

6. The needle thread

comes out on the

wrong side of the

material.

①

The needle thread tension is not high

enough.

②

The needle thread after thread trimming is

too long.

◦

Increase the needle thread tension.

◦

Increase the tension of the thread tension control-

ler No. 1.

15

15

7. Threads break

at time of thread

trimming.

①

The knife has been improperly position.

◦

Correct the position of the knife. 20

8. Thread end of the

1st stitch comes

out on the right

side of the materi-

al.

①

Stitch skipping at the 1st stitch.

②

Needle used and thread used are thick

in terms of the inner diameter of the inter-

mediate presser.

③

Intermediate presser is not properly posi-

tioned in terms of the needle.

④

The direction of air blower is incorrect.

As a result, needle thread at the tip of

needle cannot be clamped with the disc

presser.

◦

Increase the length of needle thread remaining at

the needle after thread trimming.

◦

Change the current intermediate presser with

another one which has a larger inner diameter.

◦

Adjust the eccentricity between intermediate

presser and needle so that needle enters in the

center of intermediate presser.

◦

Adjust the air-blowing direction of the air blower

according to the direction of sewing so that the

needle thread at the tip of needle can be clamped

with the disc presser.

15

37

―

―

9. The needle thread

is entangled in the

inner hook holder.

①

The clearance provided between the

inner hook holder and the inner hook is

too small.

◦

Adjust the clearance provided between the inner

hook holder and the inner hook appropriately

according to the thickness of needle thread to be

used.

20

10. The knotting

section of bobbin

thread at 2nd

stitch at the sew-

ing start appears

on the right side.

①

The bobbin runs idle excessively.

②

Bobbin thread tension is too low.

③

The needle thread tension at 1st stitch is

too high.

◦

Adjust the height of idling prevention spring of the

bobbin case appropriately.

◦

Increase the bobbin thread tension.

◦

Decrease the needle thread tension at 1st stitch.

―

15

―

Loading...

Loading...