10.8.7 Option lb

Engine air intake shut-off valve maintenance

Material Compressed air for blowing out

Petroleum ether or spirit

Cleaning cloth

Precondition The machine is shut down.

The machine is fully vented, the pressure gauge reads 0 bar.

Machine is cooled down.

All compressed air consumers are disconnected and the air outlet valves are open.

NOTICE

Engine air intake shut-off valve

The engine air intake shut-off valve does not close when flammable gas is drawn into the

engine:

The machine does not shut down? Destruction of the engine and explosion and/or fire are

possible!

➤ Do not move the valve adjusting screw.

➤ Have the valve set by a specialist workshop or KAESER Service.

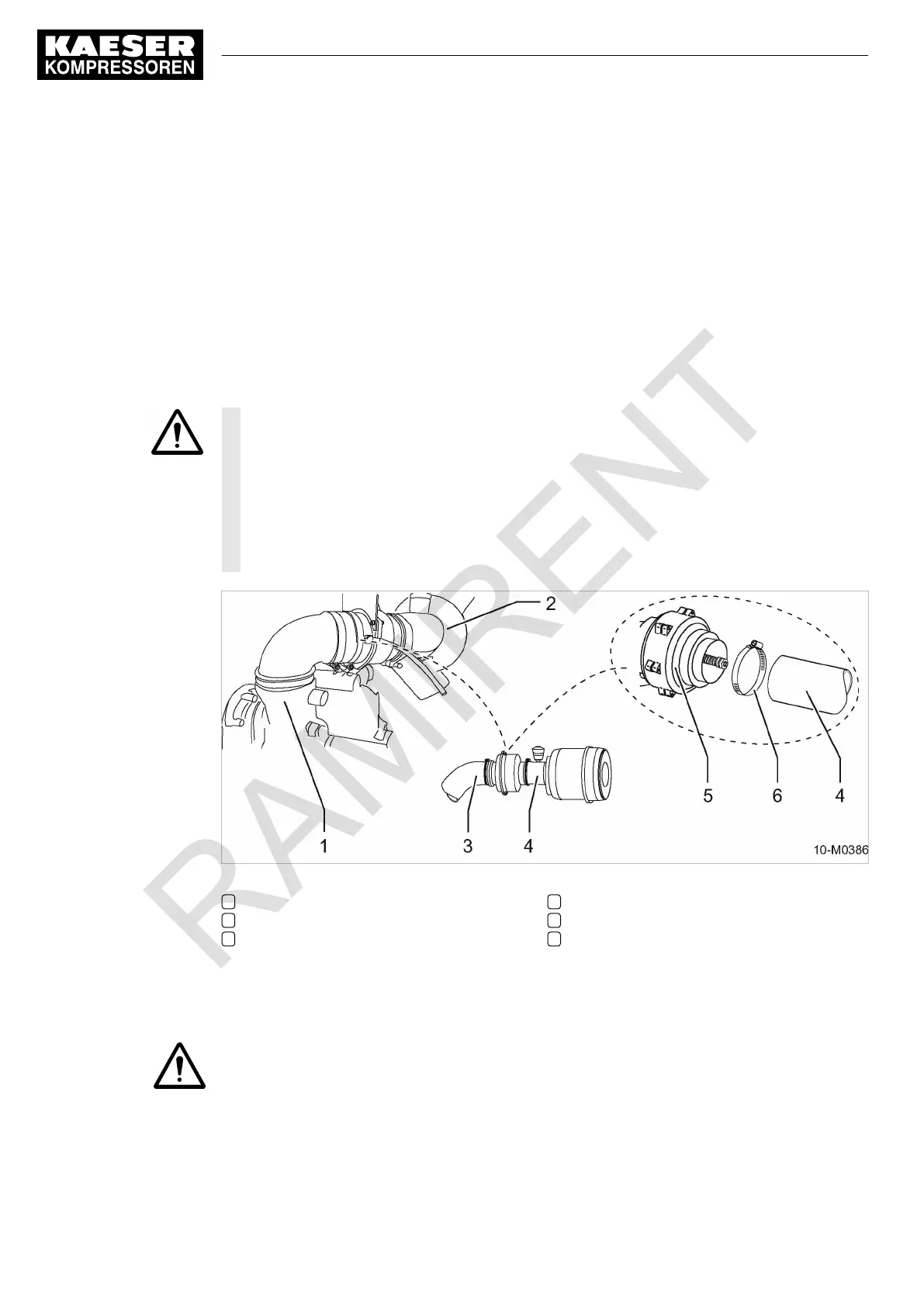

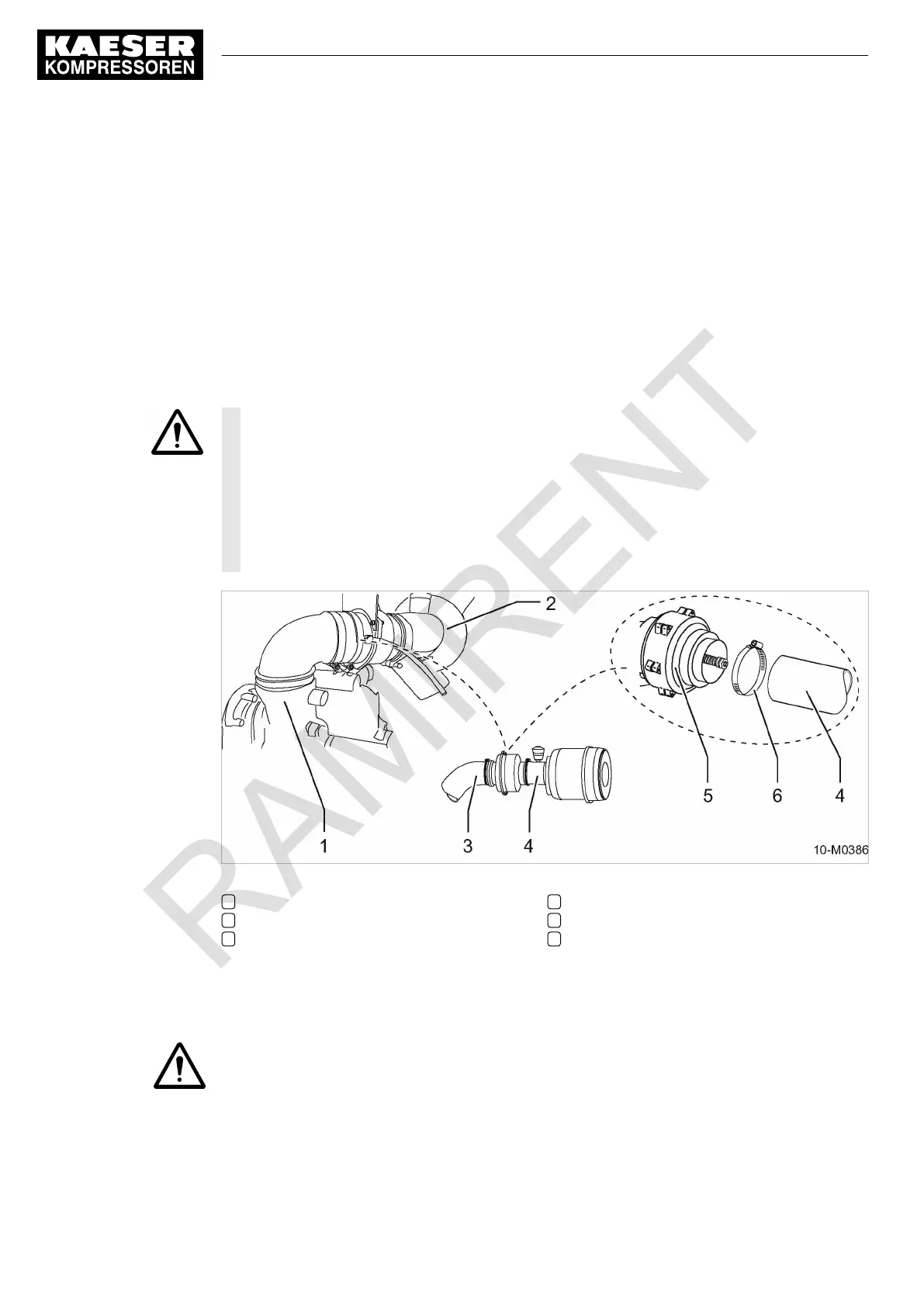

Fig. 78 Engine air intake shut-off valve maintenance

1 Engine air intake

2 Engine air filter

3 Air intake hose (engine side)

4 Air intake hose (filter side)

5 Engine air intake shut-off valve

6 Hose clamp

➤ Open both doors.

Cleaning the engine air intake shut-off valve:

1.

NOTICE!

The engine air intake shut-off valve does not close fully.

The machine does not shut down? Destruction of the engine and explosion and/or fire are

possible!

➤ Do not grease the valve, as this may cause a build up of dust and valve sticking.

2. Loosen the hose clamp on the filter side of the valve and turn the air intake hose to one side.

10 Maintenance

10.8 Maintenance of Optional Items

146

Service manual Portable compressor

M122

No.: 9_6974 20 E

Loading...

Loading...