A metering valve on the lubricator regulates the amount of oil in the compressed air:

■

minimum oil to lubricate the tools and prevent corrosion,

■ more oil for cleaning and to prevent wear in the tools.

The oil flow can be stopped by a shut-off valve.

The oil flow adjusts automatically to changes in air demand (one or more tools/consumers on line).

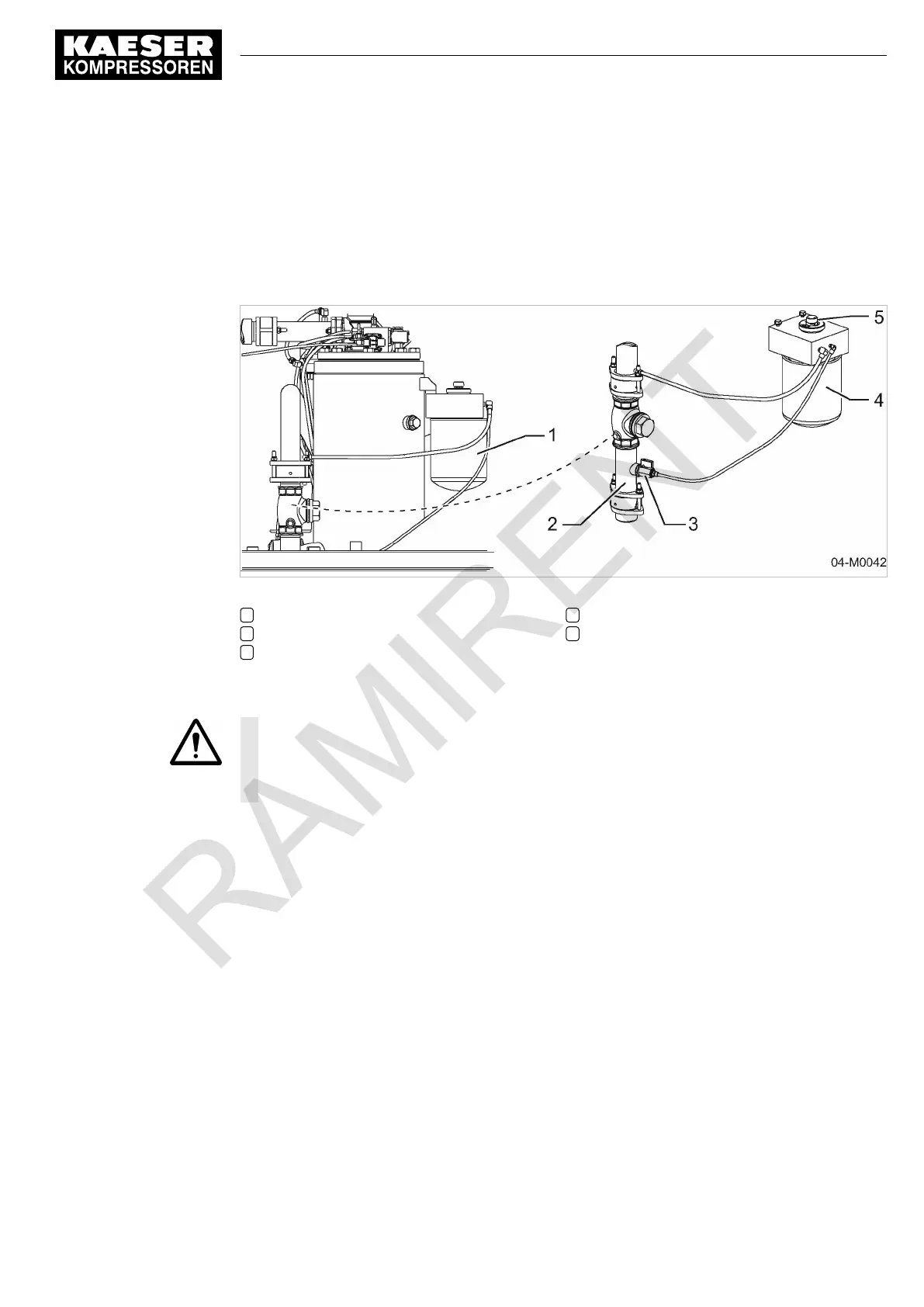

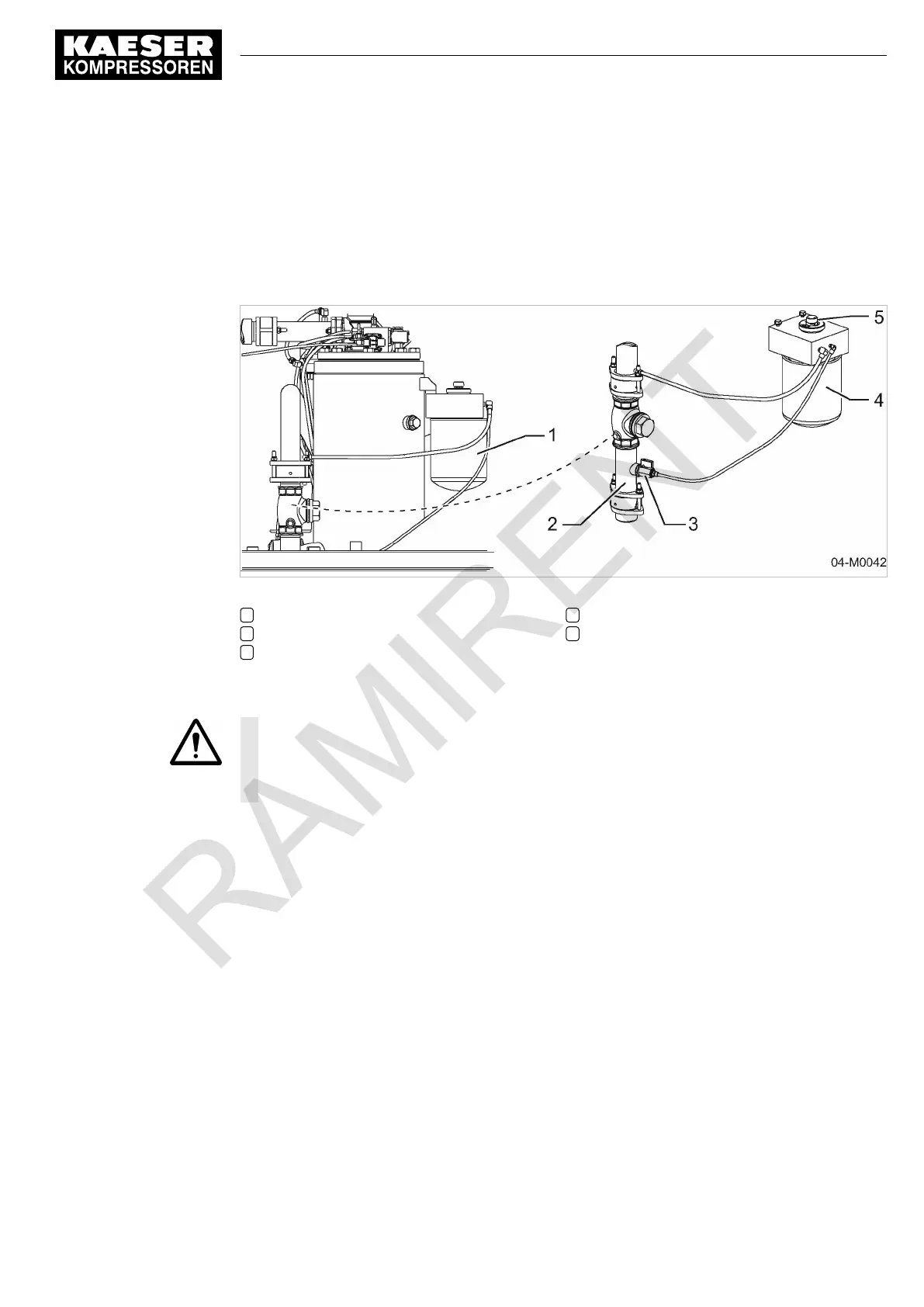

Fig. 9 Tool lubricator

1 Tool lubricator

2 Air line

3 Shut-off valve

4 Oil tank

5 Metering knob

Points to be observed with separate compressed air lines:

NOTICE

Lubrication with tool oil.

Air tools that must not be lubricated can be damaged.

➤ Blow any residual oil out of the line before connecting such an air tool.

4.7.2 Option ba, bb

Low temperature equipment options

Special equipment is provided for operation in extremely low temperatures.

This equipment guarantees machine operation at temperatures from -25 °C..... +50 °C .

The electrical system enables trouble-free engine starting at ambient temperatures down to -20 °C.

4.7.2.1 Option ba

Frost protection

Control air is mixed with an alcohol-based antifreeze to prevent control and regulating devices

freezing. This considerably lowers the freezing point of any moisture in the air.

4 Design and Function

4.7 Options

No.: 9_6974 20 E

Service manual Portable compressor

M122

39

Option fc

Loading...

Loading...