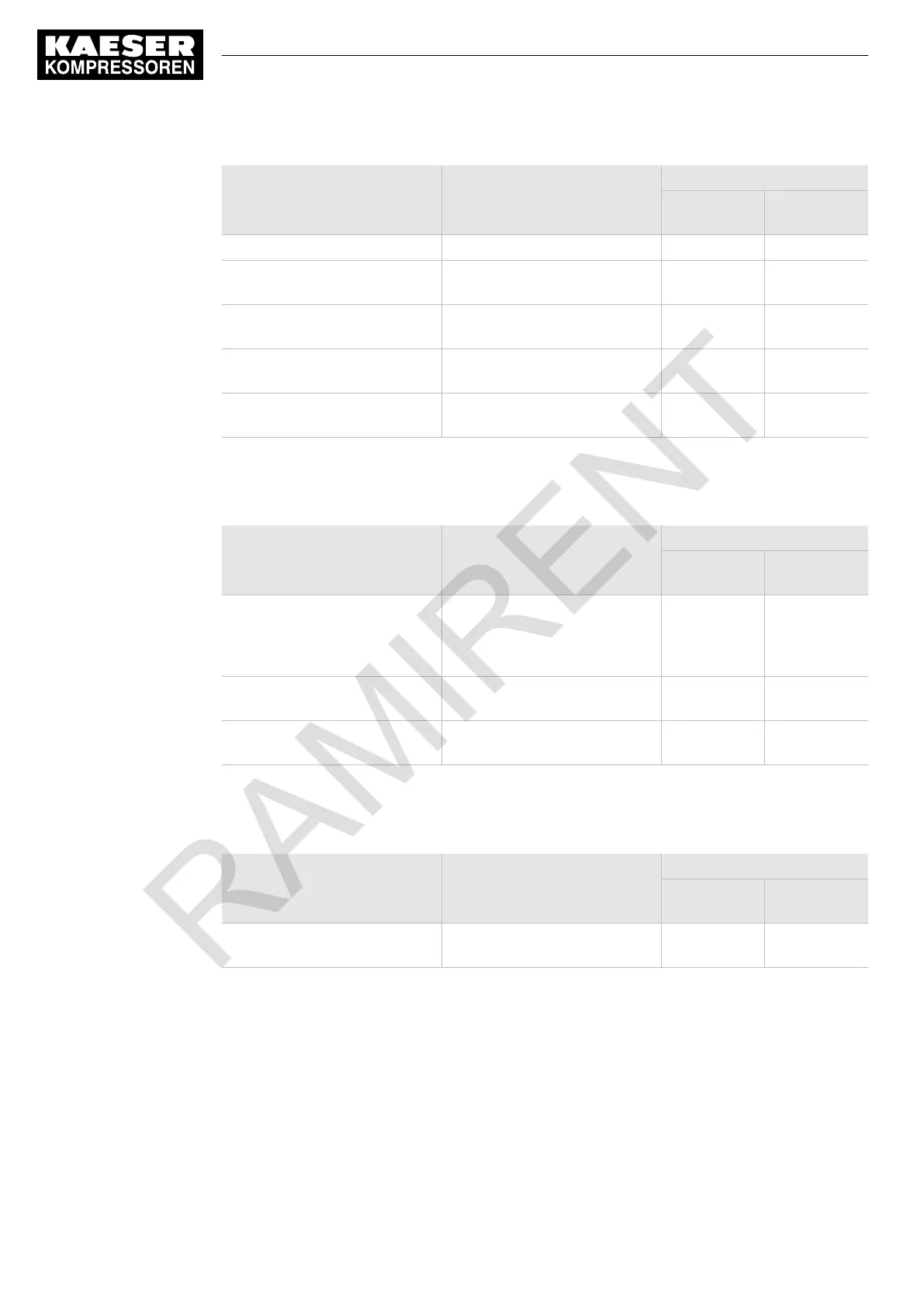

Possible cause Remedy Where can I get help?

Specialised

workshop

KAESER-ser‐

vice

Compressor oil filter clogged. Change, see chapter 10.4.4. – –

Compressor cooling oil level too

low.

Topping up, see chapter 10.4.2. – –

Oil pipes leaking. Seal leaks or have pipes

changed.

X X

Engine cooling system or cool‐

ing fan defective.

Have repaired. X X

Ambient temperature too high. See installation conditions in

chapter 5.2.

– –

Tab. 59 Fault: machine overheating

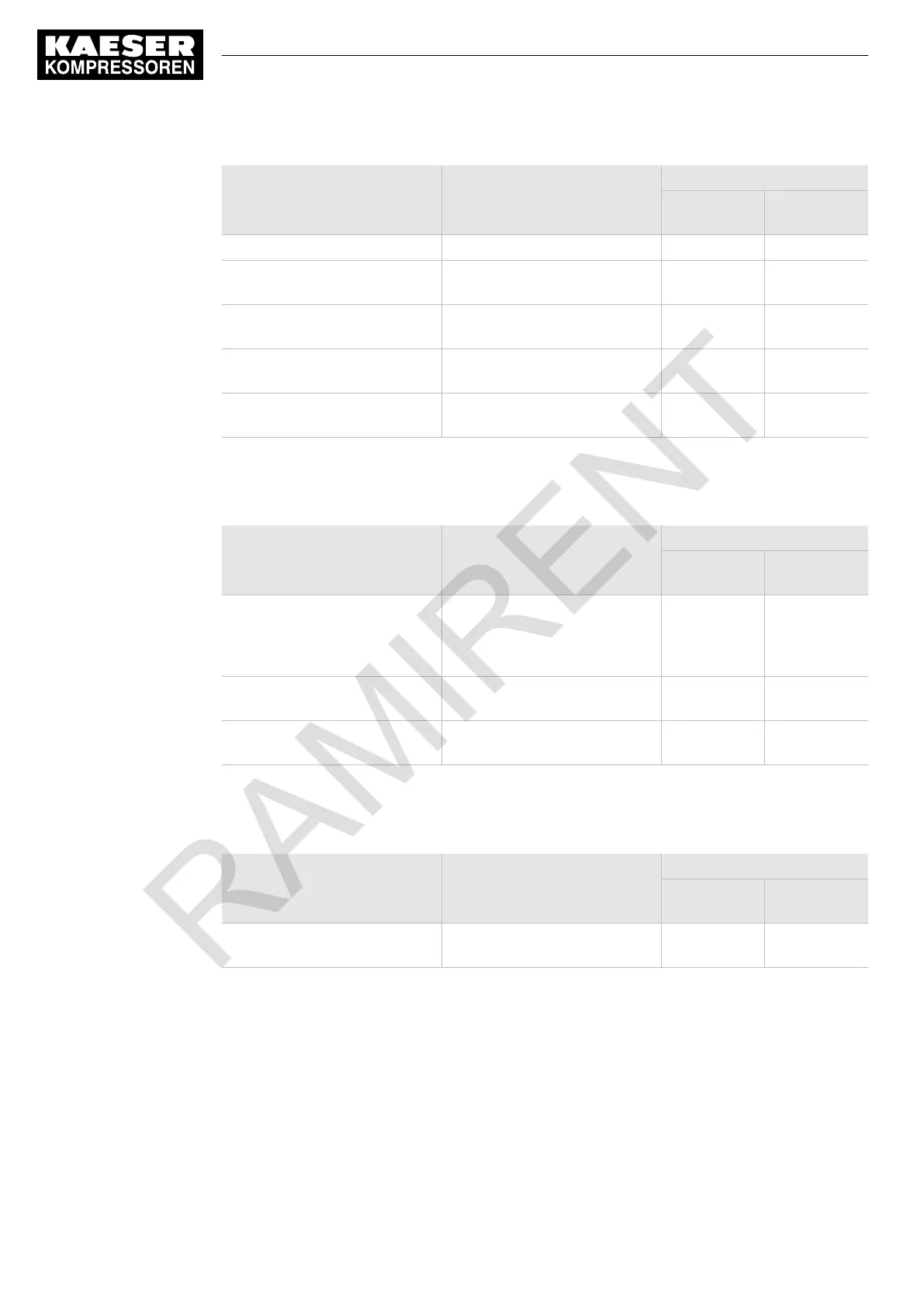

9.3.5 Too much oil residue in the compressed air

Possible cause Remedy Where can I get help?

Specialised

workshop

KAESER-ser‐

vice

Oil separator cartridge scavenge

line clogged.

Clean the oil separator cartridge

dirt trap or replace the strainer

and nozzle if necessary. See

chapter 10.4.5

.

– X

Fractured oil separator car‐

tridge.

See chapter 10.4.6 for chang‐

ing.

– –

Oil level in the oil separator tank

too high.

Reduce to maximum level, see

chapters 10.4.1 and 10.4.3.

– –

Tab. 60 Fault: too much oil residue in the compressed air

9.3.6 Oil flows from the compressor air filter after shutdown

Possible cause Remedy Where can I get help?

Specialised

workshop

KAESER-ser‐

vice

Defective non-return function of

the inlet valve.

Repair or have replaced if nec‐

essary.

– X

Tab. 61 Fault: oil flows from the compressor air filter after shutdown

9 Fault Recognition and Rectification

9.3 Evaluate compressor faults and alarms

76

Service manual Portable compressor

M122 No.: 9_6974 20 E

Loading...

Loading...