7.12.3.8 Angular reset

An input can be dened via the parameter "reset master/slave difference input selection" (ps.11) that sets the

current angle difference between master and slave to zero.

At the rising edge of the input, the master position (= ru.56 "set point position") is set equal to the slave position

(= ru.54 "actual position"). Resetting the angle adjustment is done without ramps. Switching condition "drive

running synchronously" remains set.

START

STOP

FUNC.

SPEED

ENTER

F/R

ANTRIEBSTECHNI K

START

STOP

FUNC.

SPEED

ENTER

F/R

ANTRIEBSTECHNI K

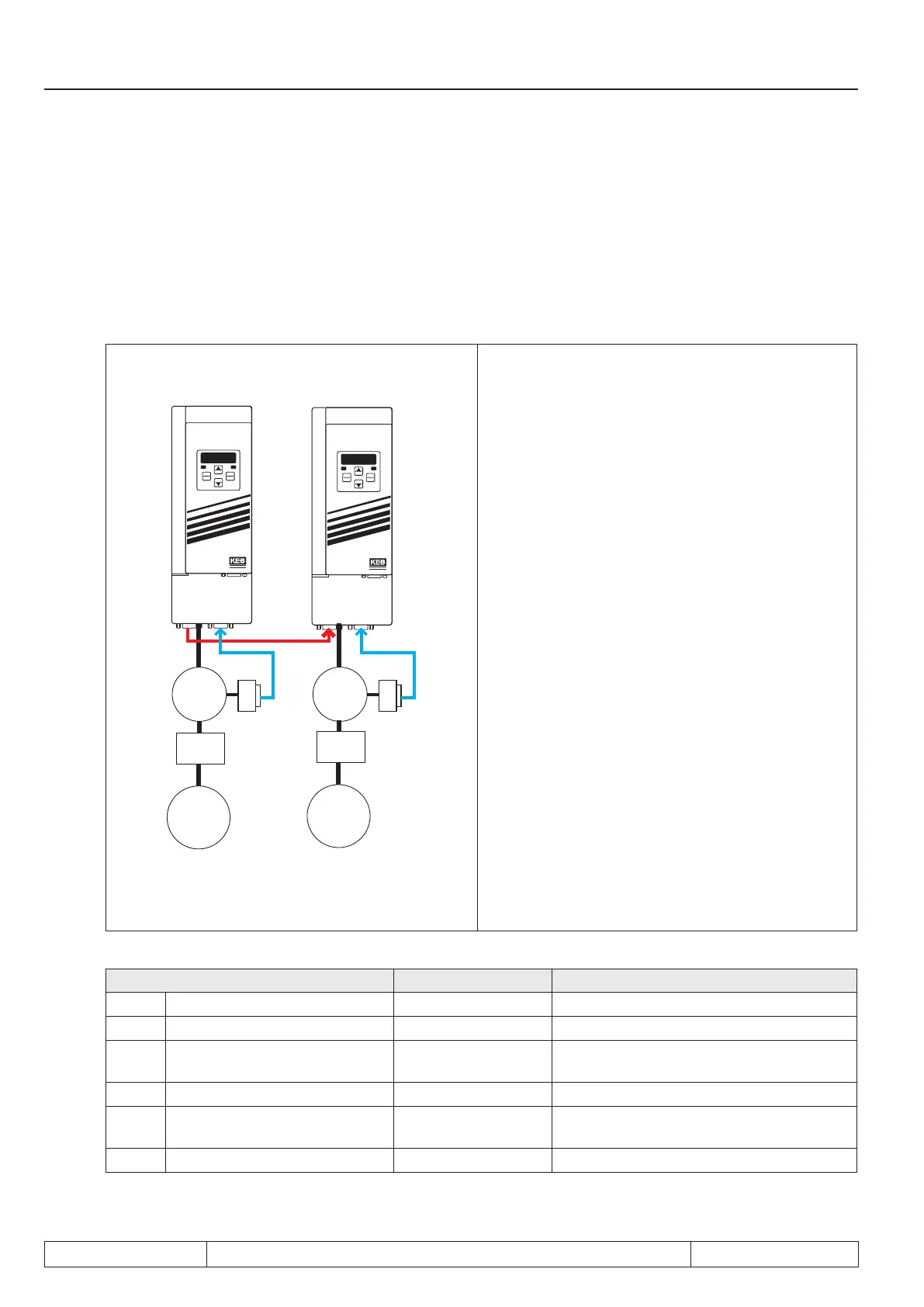

X3B X3A X3B X3A

3

~

3

~

Load

i= 5,25

Load

i= 15

speed

closed-loop

master drive

speed

closed-loop

slave drive

forward direc-

tion of rotation

reverse direc-

tion of rotation

Example of a printing press:

An F5-S serves as master shaft.

X3B of the master is incremental encoder output.

The incremental encoder analogue provides 2048

increments per revolution.

The master transmission has a gear ratio of 15 to 1.

An F5-S serves as slave.

X3B of the slave is incremental encoder input.

The slave transmission has a gear ratio of 5 to 1.

Parameter list for the slave shaft:

Parameter Value Notice

cS.00 Controller conguration 4: vector controlled

cS.01 actual source 0: Channel 1 Speed feedback is channel 1

PS.00 Posi-/synchronous mode

1: Synchronous

mode

PS.01 Actual position source 1: Channel 2 Master position via channel 2

PS.02 Posi / synch input selection 1: ST (X2A.16)

Synchronous running active, as soon as

control release is given

PS.06 KP pos/syn 100 Kp unequal 0 => angular-synchronous

Page 7.12 - 26 COMBIVERT F5-A, -E, -H © KEB, 2012-10

Posi- and synchronous operating

Loading...

Loading...