9.8 Removing faults / warnings

Depending on the conditions in your installation, there may be a wide variety of reasons for the

fault. In multi-axis systems there may be further hidden causes of a fault.

Detailled hints for removal of faults can be found in the Online Hilfe chapter

"Trouble-Shooting".

Our customer service can give you further assistance with problems.

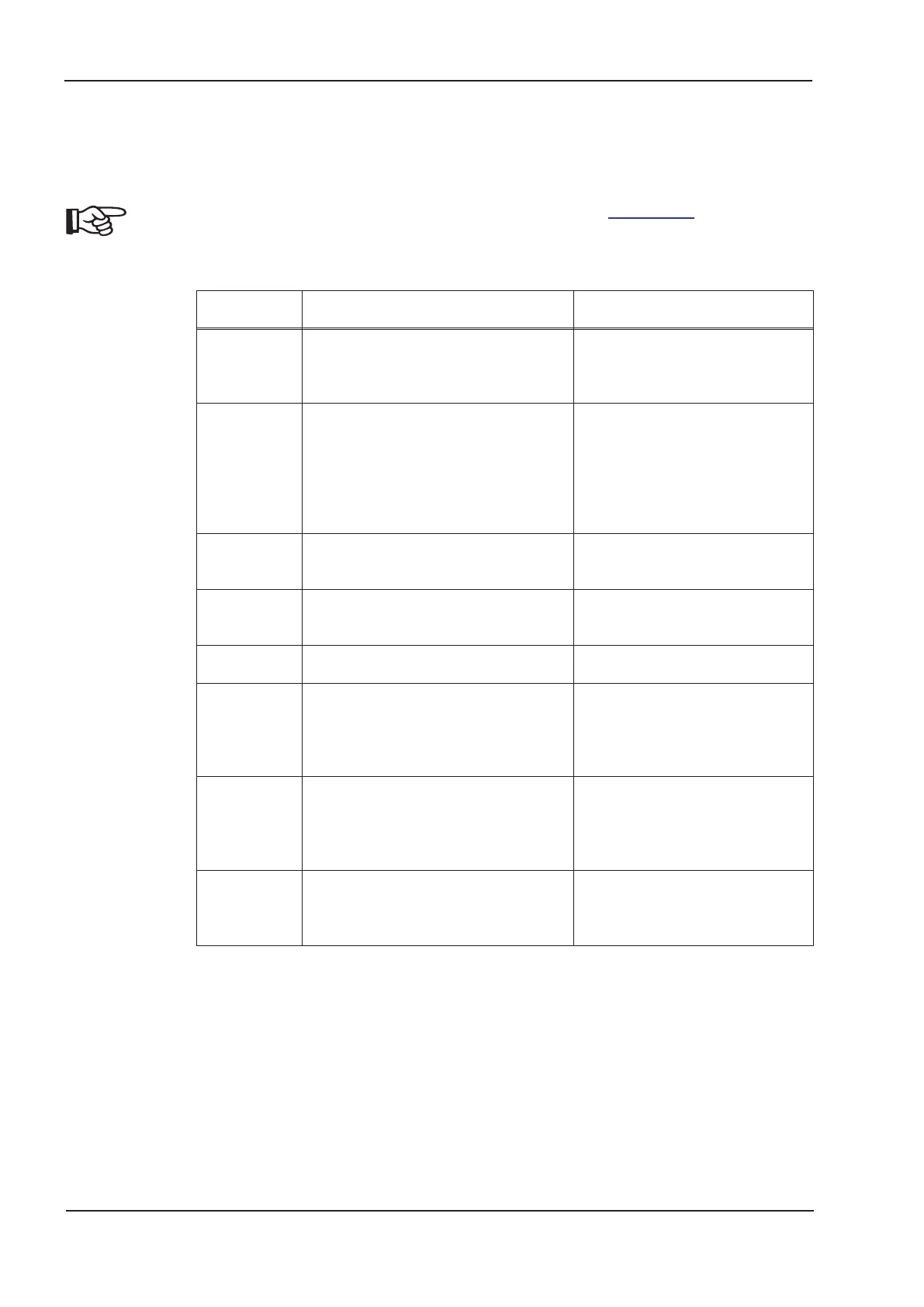

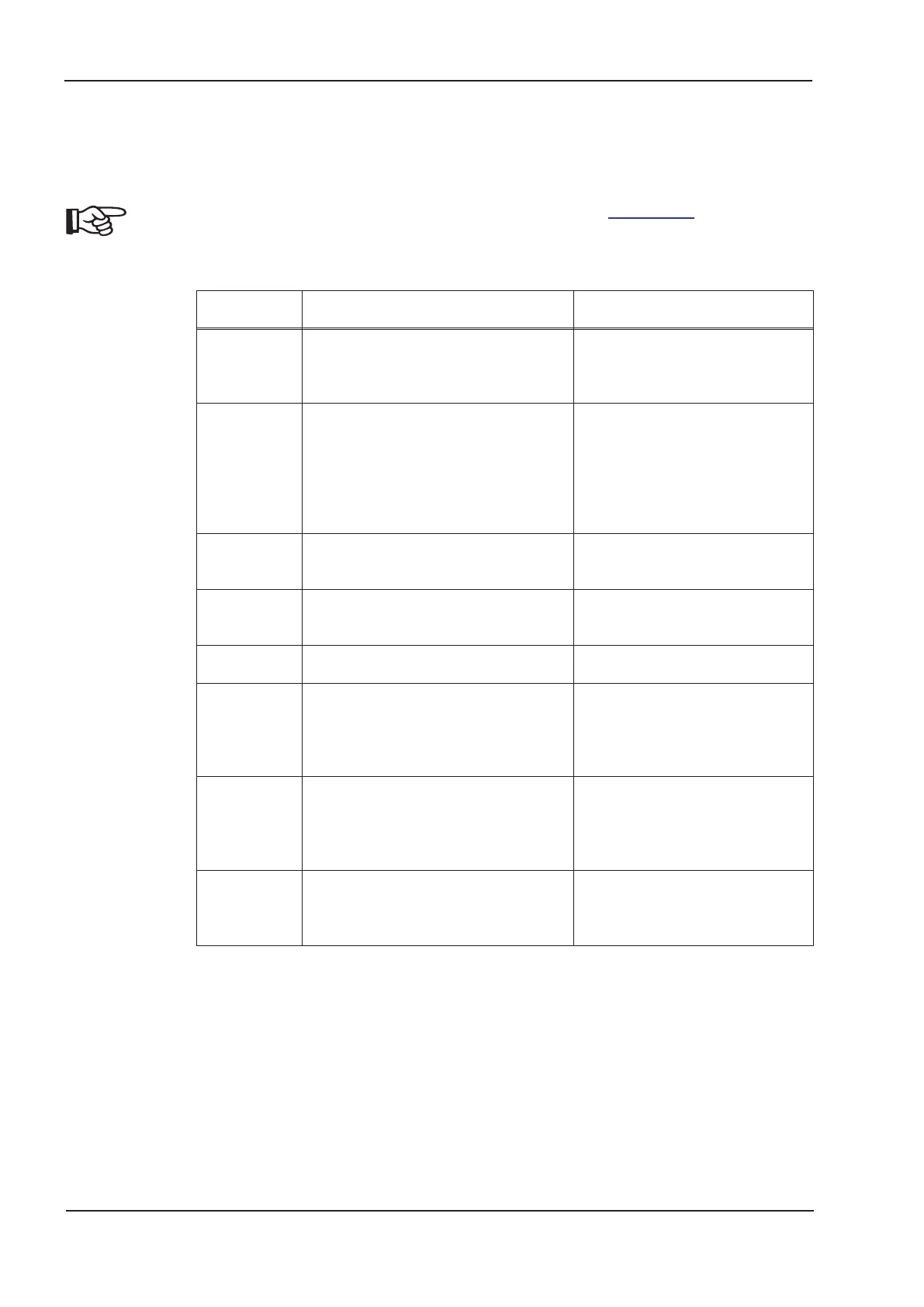

Fault possible causes

Measures to remove the cause of

the fault

HMI message:

communicati

-

on fault

— wrong cable used

— cable plugged into wrong position

in servo amplifier or PC

— wrong PC interface selected

— use null-modem cable

— plug cable into the correct sockets

on the servo amplifier and PC

— select correct interface

motor does

not rotate

— servo amplifier not enabled

— break in setpoint cable

— motor phases swapped

— brake not released

— drive is mechanically blocked

— no. of motor poles set incorrectly

— feedback set up incorrectly

— apply enable signal

— check setpoint cable

— correct motor phase sequence

— check brake control

— check mechanism

— set no. of motor poles

— set up feedback correctly

motor

oscillates

— gain too high (speed controller)

— shielding in feedback cable broken

— AGND not wired up

— reduce Kp (speed controller)

— replace feedback cable

— join AGND to CNC-GND

drive reports

following error

—I

rms

or I

peak

is set to low

— setpoint ramp is too long

— increase I

rms

or I

peak

(keep within motor data !)

— shorten setpoint ramp +/-

motor over-

heating

—I

rms

/I

peak

set too high — reduce I

rms

/I

peak

drive too soft

— Kp (speed controller) too low

— Tn (speed controller) too high

— PID-T2 too high

— T-Tacho too high

— increase Kp (speed controller)

— use motor default value for

Tn (speed controller)

— reduce PID-T2

— reduce T-Tacho

drive runs

roughly

— Kp (speed controller) too high

— Tn (speed controller) too low

— PID-T2 too low

— T-Tacho too low

— reduce Kp (speed controller)

— use motor default value for

Tn (speed controller)

— increase PID-T2

— increase T-Tacho

axis drifts at

setpoint = 0V

— offset not correctly adjusted for analog

setpoint provision

— AGND not joined to the CNC-GND of

the controls

— adjust setpoint-offset (analog I/O)

— join AGND and CNC-GND

96 SERVOSTAR

®

640/670 Instructions Manual

Setup

12/2010 Kollmorgen

Loading...

Loading...