PRE-START INSPECTION

The operator should inspect the machine thoroughly

before each use. Visually inspect the unit for

familiarization and to check its general condition.

Continue with a check of special systems and

components. Daily inspections will maintain the life and

reduce maintenance costs for your LeeBoy 3000C

Force Feed Loader.

• Ensure that all the instruction and safety decals are in

place and legible.

• Ensure operator’s area is free from debris.

• ALWAYS wear OSHA required safety equipment when

operating the loader.

• Be sure that any malfunctioning, broken, worn or

missing parts are repaired or replaced before

operating the machine.

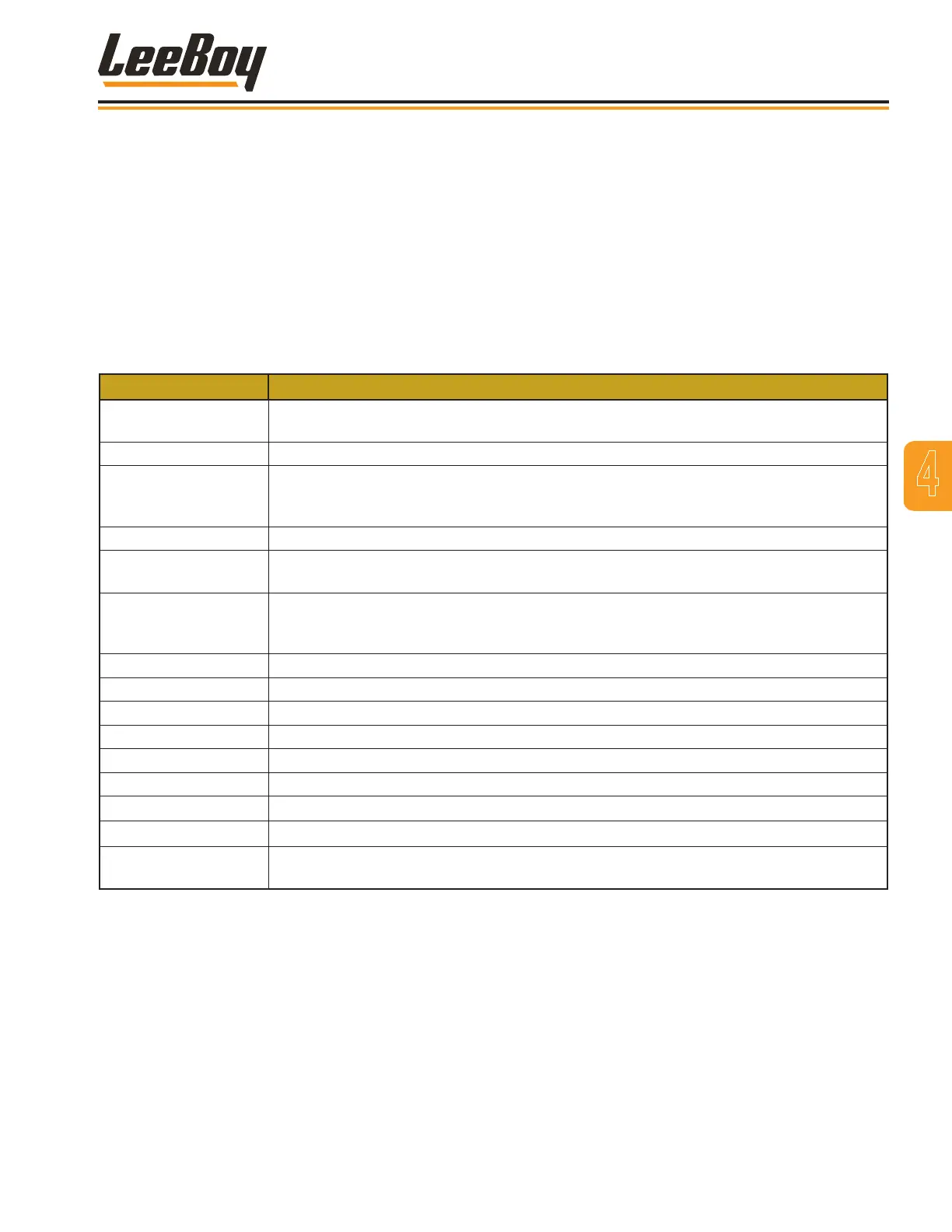

Table 1-1. Operator Inspection List

INSPECTED ITEM PROCEDURE

Hydraulic

Check hydraulic oil level and ll if needed using Citgo All-Temp. Inspect the tank for any

leaks.

Fuel Check fuel guage on the gauge panel for fuel level and ll if needed.

Engine Oil

The engine oil level is measured on the right side of the engine. Open the access door to

access dipstick. Make sure oil is clean and falls between the two marks on the dipstick.

Use 15W40 if needed to ll.

Radiator Check the coolant level.

Battery

Check cables for damage. Ensure cables are tight and clean. Check for corrosion on the

battery terminals and clean if needed.

Air Cleaner

Check the air lter element and hose connections. Air cleaner has both a primary and

secondary lter. If the air cleaner indicator is red, the air lters need replacement. Reset

the indicator by pressing the button on top of it.

Planetary Axle Check oil level. Drain and replace after the rst 50 hours of operation.

Tire Pressure Check for proper ination. (45 PSI Rear and 90 PSI Front.)

Drain Plugs Make sure plugs are installed and tight.

Engine Belt Check for proper tension of belt. Check for wear and replace if needed.

Grease Fittings Make sure the ttings are greased and in good working order.

Lug Nuts Make sure lug nuts are tight and torqued to the correct value.

Front Axle Pin and cotter key and all bolts.

Conveyor Belt Ensure the conveyor belt is centered.

Pump Box

Check pump box oil level using the dipstick on rear side of the engine. Oil level should be

lled to the top of the knurled surface.

4

Operation

3000C Force Feed Loader 4-5

Loading...

Loading...