Swivel Conveyor (Option)

The main conveyor must be fully

raised with the safety pins inserted in the conveyor

supports before operating the swivel.

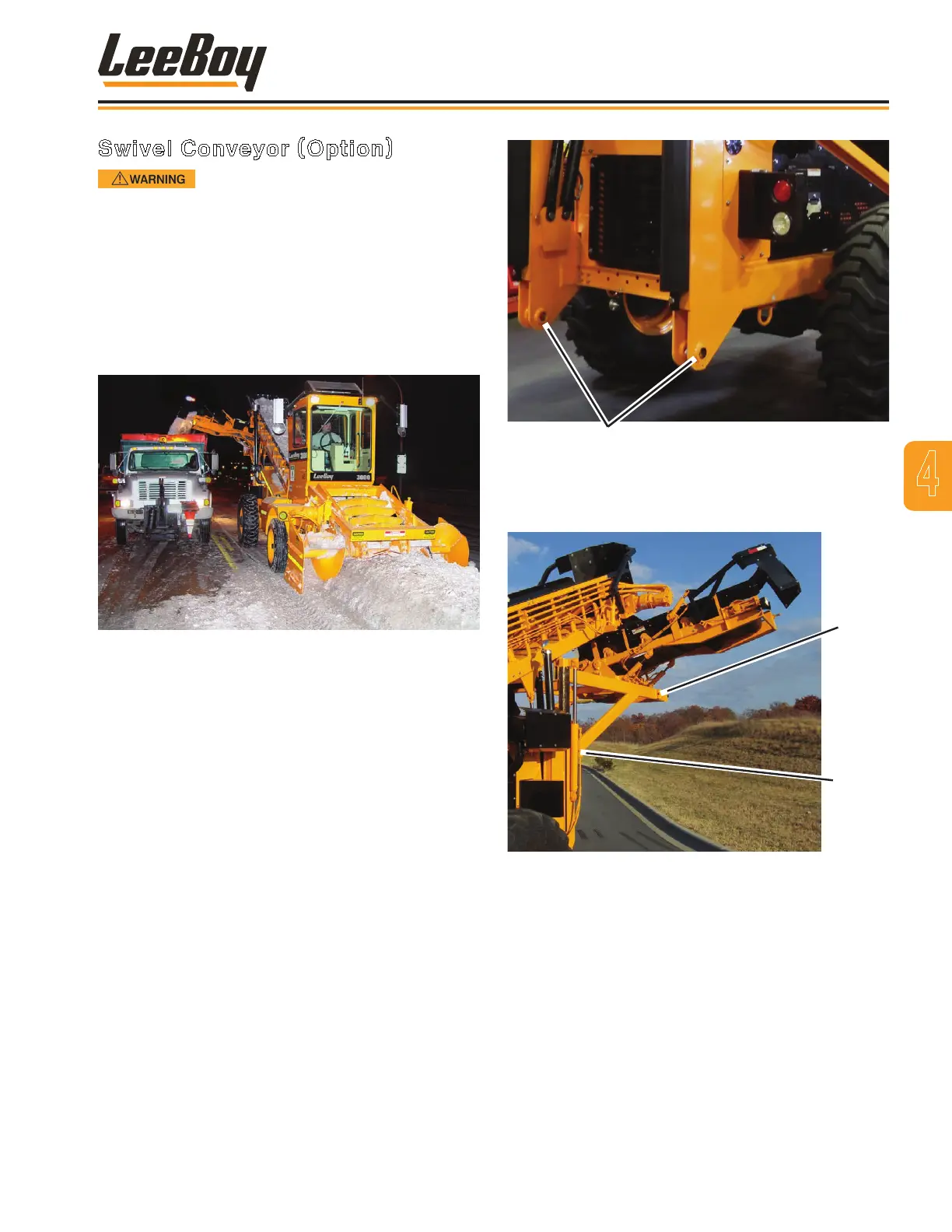

The operational swivel conveyor gives the operator the

ability to direct material to the right, left or rear of the

machine. The swivel conveyor can move anywhere in

a 180-degree angle from the main conveyor, directing

material wherever you want it to go. This feature allows

the receiving truck to travel beside the loader in the

same direction as it receives material. (Figure 4-14)

Figure 4-14. Swivel Conveyor on Job Site

The operator will need to become familiar with using the

swivel conveyor as the main conveyor could overload

the swivel if operating too fast. The swivel conveyor

switch is on the console to the right of the operator’s

console. (Page 3-4)

The swivel conveyor is factory-installed, but it can be

removed and reinstalled as needed. To remove the

component:

1. Park the loader on a level surface. This is critical for

ensuring the assembly is stable once removed.

2. Raise rear main conveyor and install safety support

pins. (Page 4-4)

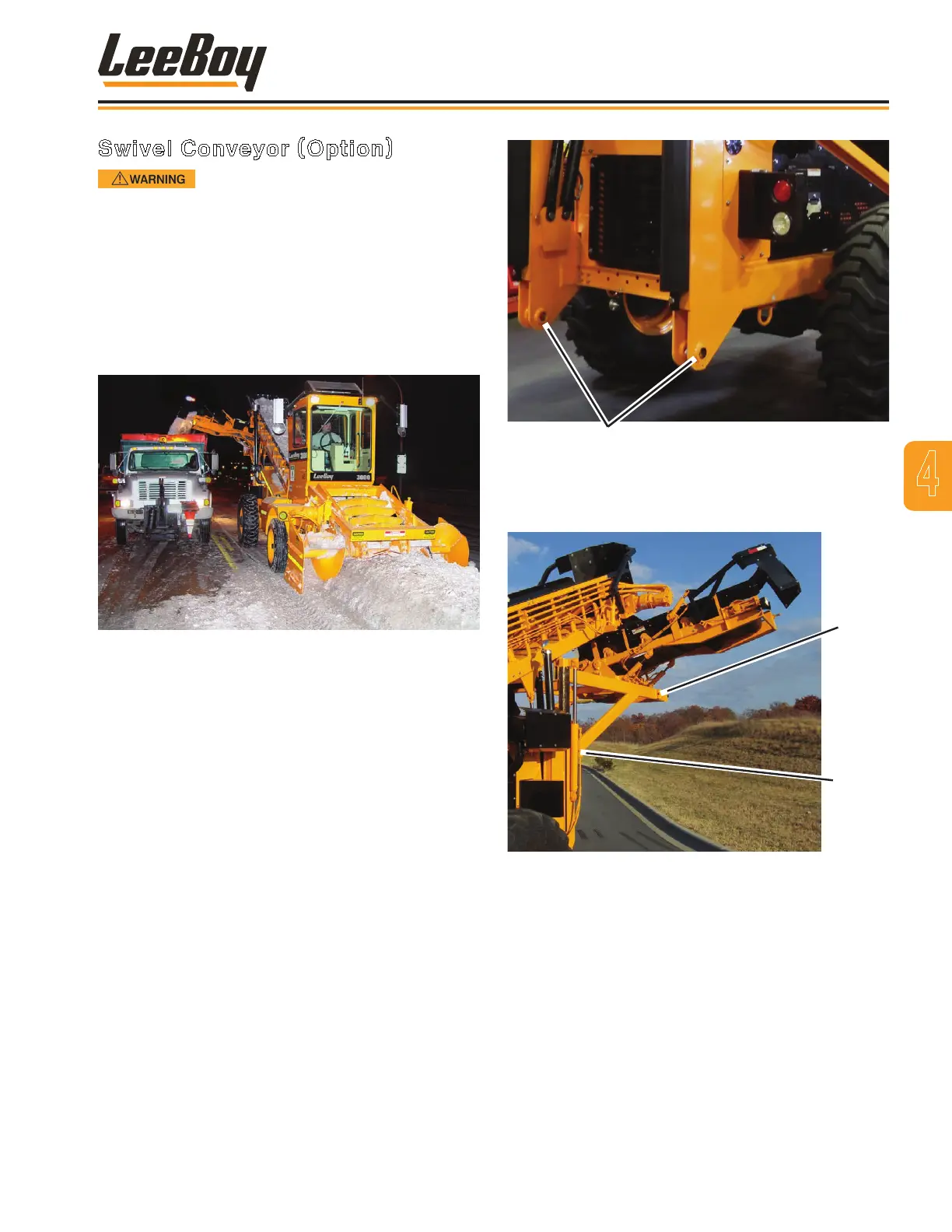

3. Raise the swivel assembly high enough to install the

rear long leg stands. (Figure 4-16)

Pins

Figure 4-15. Locking Pins

4. Lower swivel assembly slowtly to take the weight off

locking pins. Remove locking pins. (Figure 4-16)

Long

Leg

Short

Leg

Figure 4-16. Leg Stands

5. Raise the swivel assembly high enough to install the

short leg stands.

6. Lower the swivel assembly again so the mounting

hooks clear the frame.

7. Remove all swivel assembly connection hoses from

the hydraulic bulkhead. Be sure to label each hose

for its location for ease of reinstalling. (Figure 4-17)

4

Operation

3000C Force Feed Loader 4-13

Loading...

Loading...