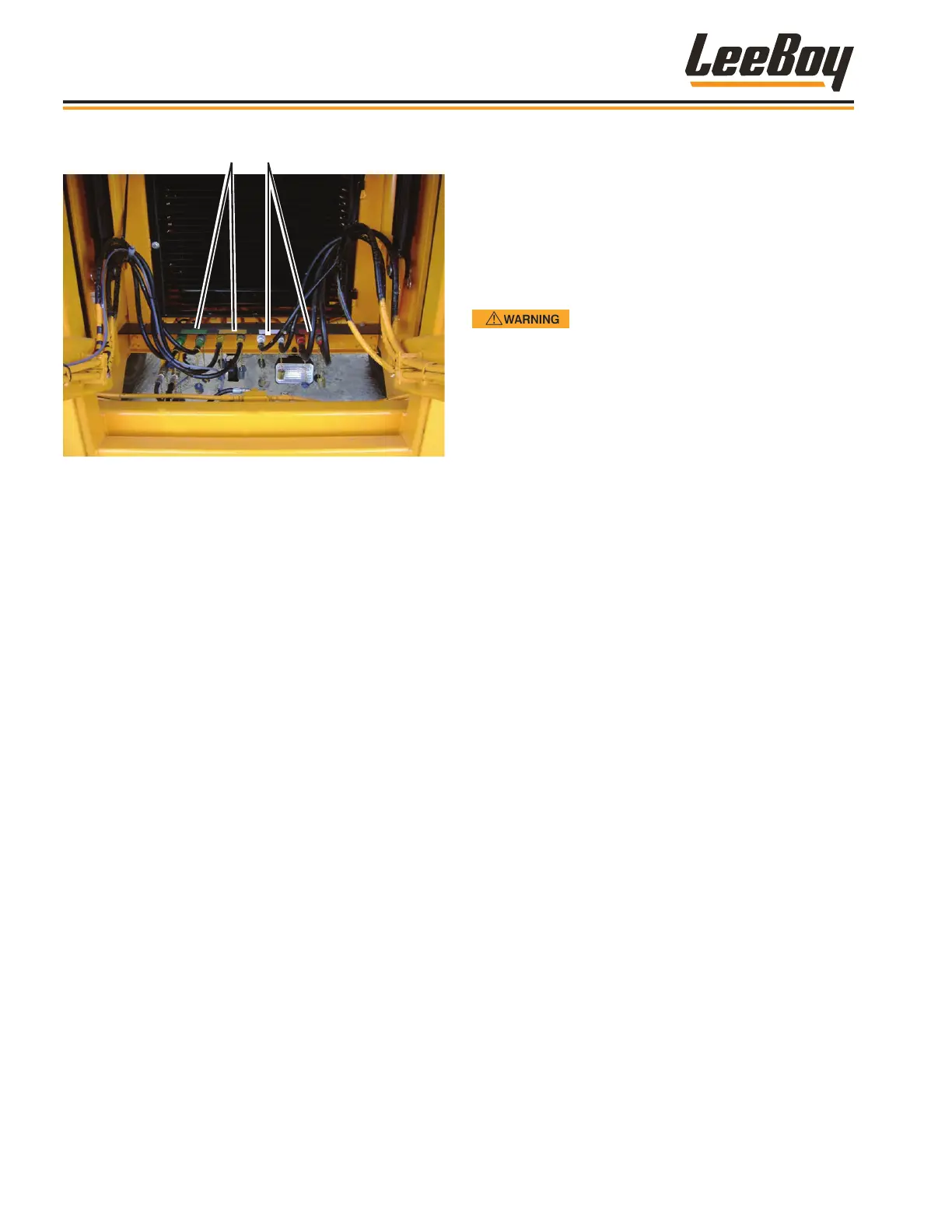

Hoses

Figure 4-17. Connection Hoses

8. SLOWLY drive the loader away from the swivel

assembly.

9. Reinstall the two locking pins for use during

reassembly.

To reinstall the assembly, simply reverse the steps

above.

LOADING MATERIAL

1. Raise conveyor to work height. (For better

performance of the belt tracking, place support pins

in holes in the rear stabilizer).

2. Set the deector to the desired position. (Figure

4-10)

3. Using the moldboard lever, align the pointers on the

moldboard.

4. Using the conveyor lever, SLOWLY oat the

moldboards down until they touch the ground and

take lever out of oat.

5. Return to the conveyor lever, lifting the moldboards

so they are slightly touching the ground.

6. Place the moldboard lever in oat at this time. (This

will put the minimum amount of weight on the cutting

edges for prolonged life).

7. Align truck with conveyor.

8. Set RPM to desired speed (full RPM for maximum

production).

9. Pull the feeder chain lever to desired speed.

10. Pull discharge conveyor lever to full speed, unless

using swivel conveyor.

11. Using the direction lever, move forward into the

material. Be sure not to overload the belt.

12. Using the conveyor lever, raise and lower the

front of the conveyor as needed, ensuring the

moldboards are at on the ground while keeping the

moldboard lever in oat.

ALWAYS watch out for overhead

obstacles while operating conveyor.

13. The deector may be used to position the material in

the material truck or where desired.

14. For quick stopping, apply the foot brake. Release

the brake to resume speed or return the direction

lever to neutral.

TRANSPORTING

When transporting the loader on a trailer, the vehicle

should be large enough to safely handle the size and

weight of the loader in all driving situations.

1. Park the loader on a level surface engage the park

brake.

2. Block the wheels in both directions so the loader

will not roll.

3. Lower the deector, conveyor and cutting edges.

4. Switch the machine to low gear using the 2-Speed

gear switch on the travel control panel. (Page 3-7)

5. Load the machine onto the trailer.

6. Block the wheels in both directions.

7. Use enough chains with the strength to secure the

loader, ensuring it will not move during transport.

Connect chains to the factory-installed D-Ring tie

downs provided on various areas of the machine for

transporting purposes. (Figure 4-14)

Operation

3000C Force Feed Loader4-14

Loading...

Loading...