Fuel

Separator

Figure 4-11. Fuel Water Separator Filter

Replace the fuel and water separator lters using the

following general procedures:

1. Stop the engine.

2. Put a container under fuel lters before removing

the lter elements.

NOTE: Consider the environment when discarding

used lters and do so according to safe and

lawful practices.

3. Wipe the area around the fuel lter elements and

element mounting heads using a clean, lint-free

cloth.

4. Use a lter removal wrench to loosen and remove

fuel lter elements by turning in a counterclockwise

direction. Drain and discard the removed elements.

5. Wipe the inside area of the lter heads with a clean,

lint-free cloth. Fill the new fuel lter elements

completely with clean fuel.

6. Put clean fuel onto the element rubber gaskets.

7. Install the new fuel lter elements onto the lter

heads. Carefully tighten the elements (by hand

only).

DO NOT overtighten the fuel lter

elements onto the lter heads.

8. Start the engine and check for ANY fuel leaks.

STOP the engine immediately if any

fuel leakage is noted. DO NOT start the engine until

the leakage problem is corrected.

NEVER loosen a fuel injector line as

contents are under high pressure. DO NOT try to

bleed air by loosening injector lines.

HYDRAULIC SYSTEM

The hydraulic motors and the hydraulic cylinders use

the same hydraulic oil reservoir and hydraulic oil supply.

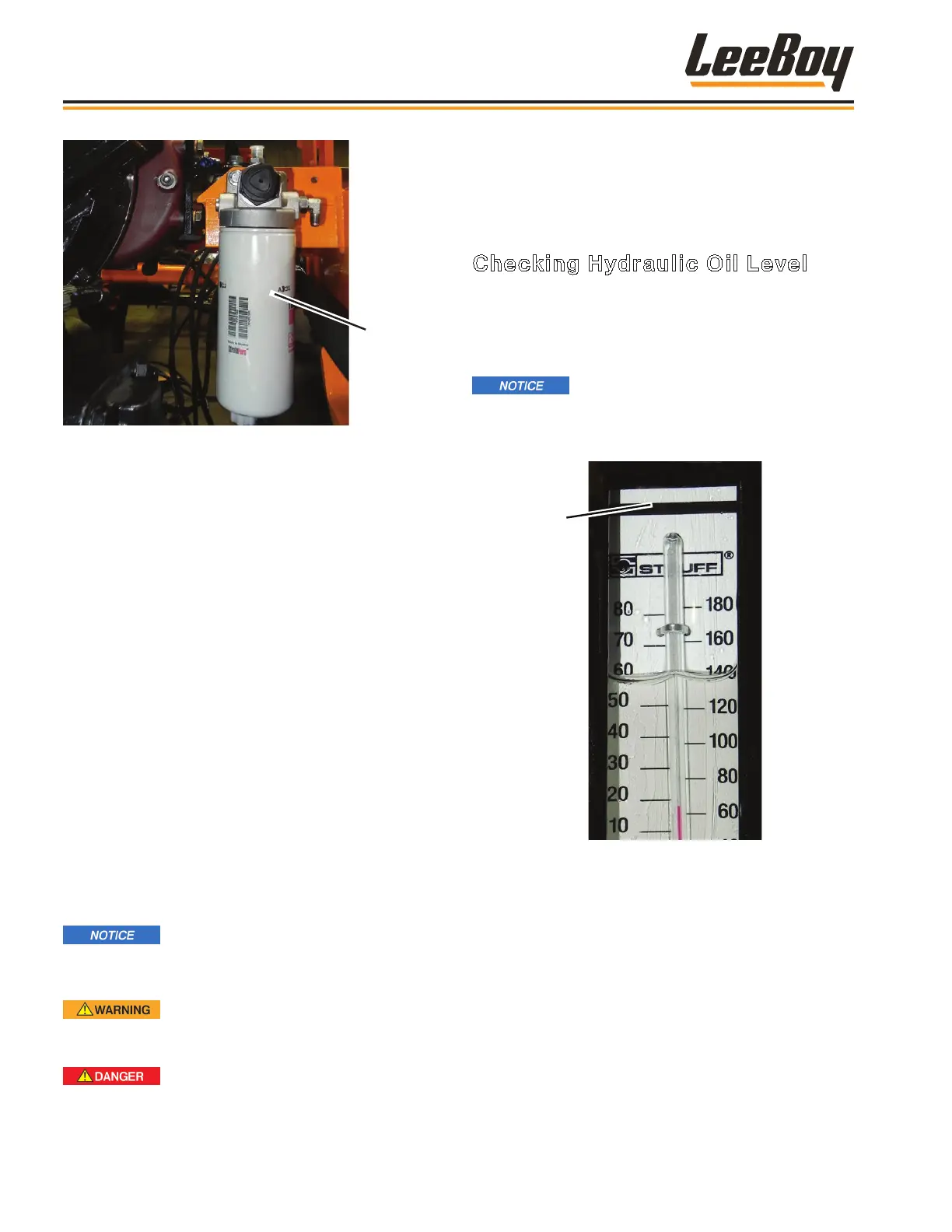

Checking Hydraulic Oil Level

1. Make sure all cylinders are retracted, so that oil

ows to tank, ensuring an accurate reading.

2. Wait 10 minutes after engine has been shut down

before checking hydraulic oil.

Oil level is determined by sight gauge.

(Figure 5-12) Hydraulic oil should be added if the

oil level falls below the ll line. Never ll above the

black ll line.

Figure 4-12. Hydraulic Gauge

3. If level is low, remove hydraulic oil ller cap to add

hydraulic oil to the tank.

4. Fill tank to the black ll line on sight gauge.

5. Screw the hydraulic oil ller cap back onto the

hydraulic tank.

Maintenance

3000C Force Feed Loader5-14

Loading...

Loading...