5555

LeeBoy 8520C Conveyor Paver 5-19

Maintenance

Change Air FilterChange Air Filter

Never operate the engine without an

air lter properly installed. Severe damage to the

machine will occur.

With extensive use, the air lter may need to be changed

more frequently. If the lter indicator gauge moves into

the red zone, clean or change the lter. (Figure 5-18)

Figure 5-18. Air Filter Cover

To change the air lter elements:

1. Raise the hood following instructions on Page 5-5.

2. Unclamp and remove air lter cover.

3. Remove the primary and secondary air lter

elements. Discard.

4. Clean the inside of the air cleaner body with a clean

cloth.

5. Install new air lter elements inside the canister.

6. Reclamp cap onto the air lter cover.

7. Check clamps to ensure lter elements are tight and

lter elements are making proper contact.

8. Start engine. If engine does not run smoothly,

recheck lter element contact.

NOTE: The air lter elements should be replaced

every 250 service hours of normal paver

operation, but more often if the paver is

operated in severe conditions.

Engine Drive BeltEngine Drive Belt

Adjust the engine drive belt every 250 service hours and

replace it every 500 hours. Regardless of the mainte-

nance interval, the engine fan belt should be replaced if

it appears frayed or cracked. This belt drives the alter-

nator and the cooling fan.

NOTE: If the fan belt is loose or damaged, and/or the

fan is damaged, it can result in overheating

or insufcient charging. Replace the fan

belt and any other damaged components

immediately.

Engine must be turned off and the key

removed before checking, adjusting or replacing the

fan belt to avoid personal injury or even death.

To adjust or replace the belt:

1. Turn off engine and remove the key. Block the

wheels to prevent movement while working on the

machine.

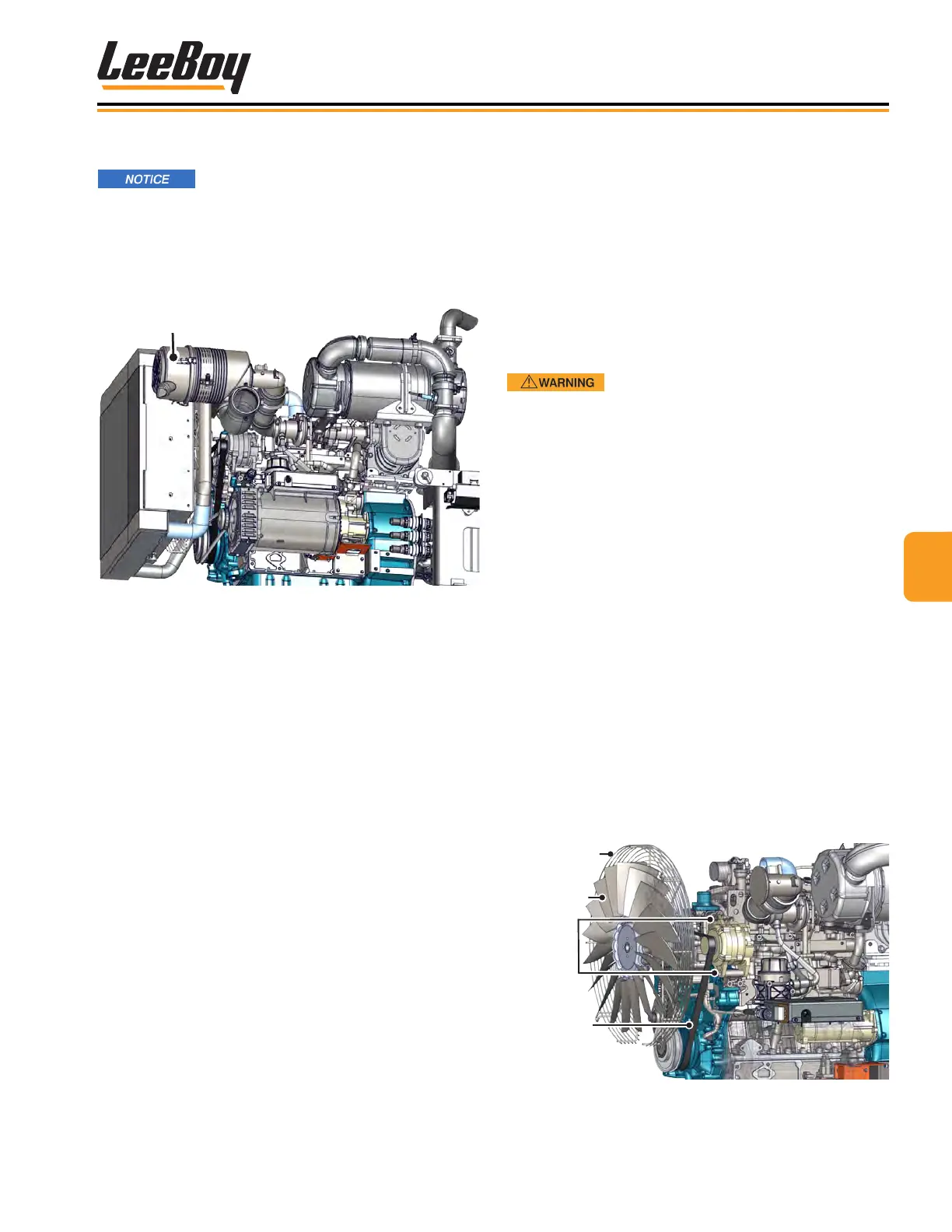

2. Remove the safety shield. (Figure 5-19)

3. Apply moderate thumb pressure to the belt between

the pulleys to gauge tension.

4. If tension is incorrect, loosen the alternator

mounting bolts and place a lever between the

alternator and the engine block.

• If adjusting the belt, pull the alternator out until

the deection of the belt (when pressed in

the middle of the span) falls within .39 to .47

inches.

• If replacing the belt, remove worn belt and

replace with new fan belt.

5. Retighten the alternator bolts and reinstall safety

shield.

Fan

Belt

Bolts

Fan

Shield

Figure 5-19. Engine Belt

Loading...

Loading...