5-4 LeeBoy 8520C Conveyor Paver

Maintenance

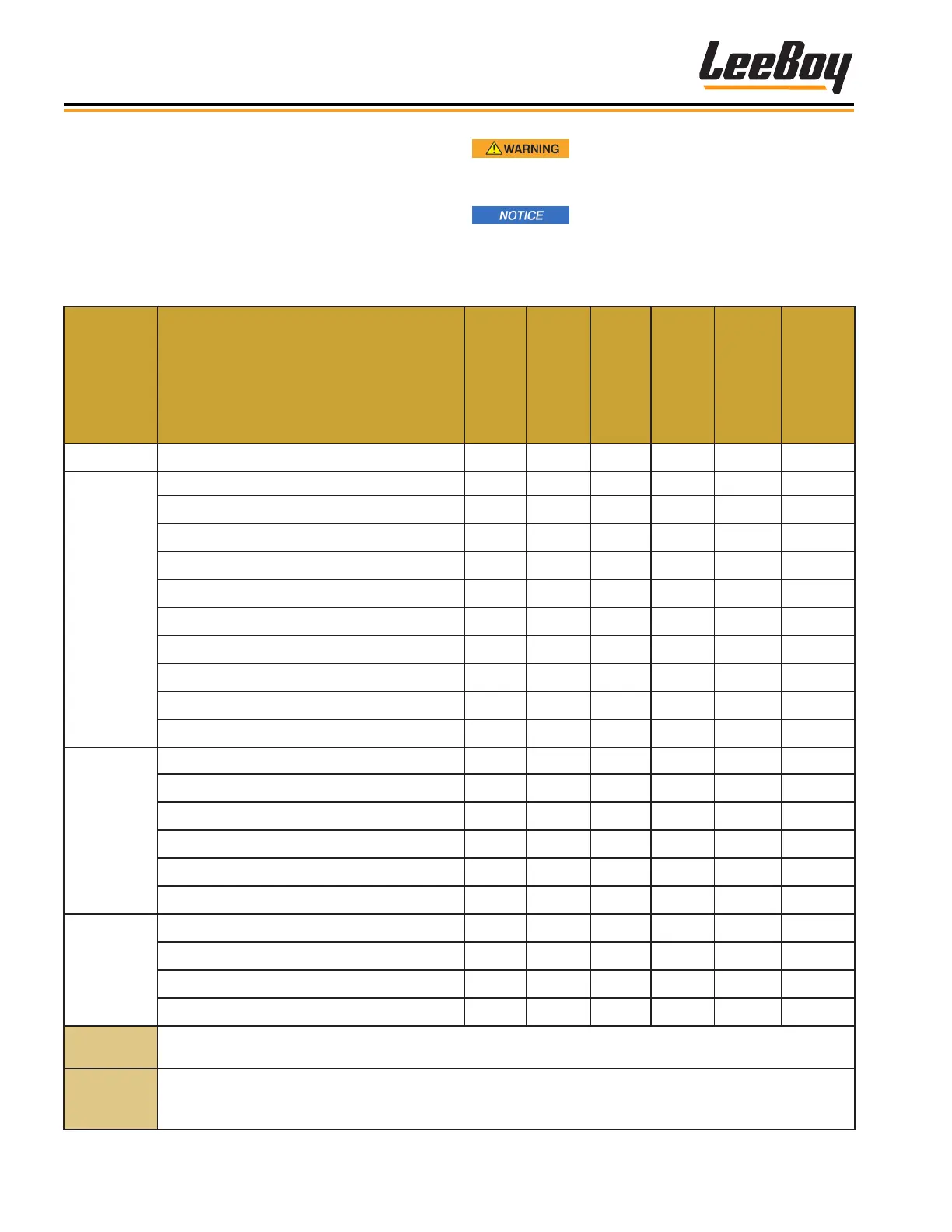

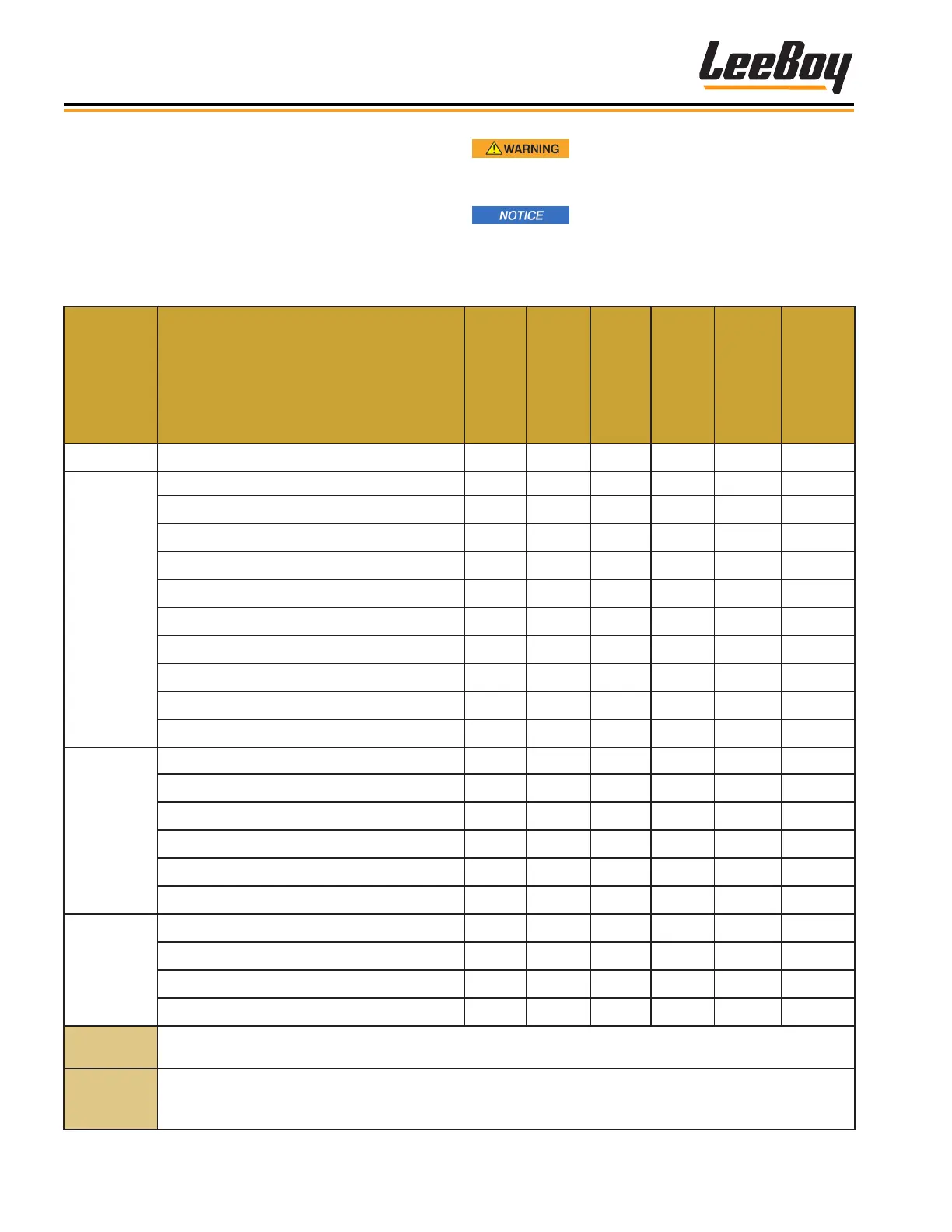

Table 5-1. Periodic Maintenance Schedule

SYSTEM ITEM

Every 10 Hours

Daily

Every 50 Hours

Weekly

Every 100 Hours

Monthly

Every 250 Hours

Quarterly

Every 500 Hours

Semi-Annually

Every 1000

Hours Annually

Paver Lubricate paver. X

Engine

Check oil level. X

Check coolant level. X

Replace coolant. X

Check air lter. X

Change air lters. X

Replace fuel lter. X

Change oil and oil lter. (Initial 50 Hours) X

Adjust engine belt. X

Replace engine belt. X

Check DEF tank uid level. Fill if needed. X

Hydraulic

Check hydraulic oil level. X

Change hydraulic oil. X

Change hydraulic lter. X

Check torque hub oil. X

Change torque hub oil. X

Drain hydraulic tank. Replace strainer. X

Mechanical

Adjust conveyor drive chains. X

Adjust conveyor ight chains. X

Adjust auger chains. X

Adjust screed extension top guide. X

Every 1500

Hours

Replace oil separator element. Contact your authorized dealer to check engine injector tip, PCV

(Positive Crankcase Ventilation) valve, and EGR cooler.

Every

3000

Hours

Contact your authorized dealer to check EGR system and turbo-charger.

Always use the appropriate and

correct sized tools for the task at hand to prevent

damage or possible injury.

When performing any routine

maintenance, always include the previous routine

maintenance hours in the higher hourly schedule.

Maintenance Schedule

Before performing any maintenance procedures on

the LeeBoy Model 8520C Conveyor Paver, review the

safety information in Section 1. Refer to the Engine

Operator’s Manual accompanying your paver for more

detailed engine service information.

Loading...

Loading...