44

LeeBoy 8520C Conveyor Paver 4-35

Operation

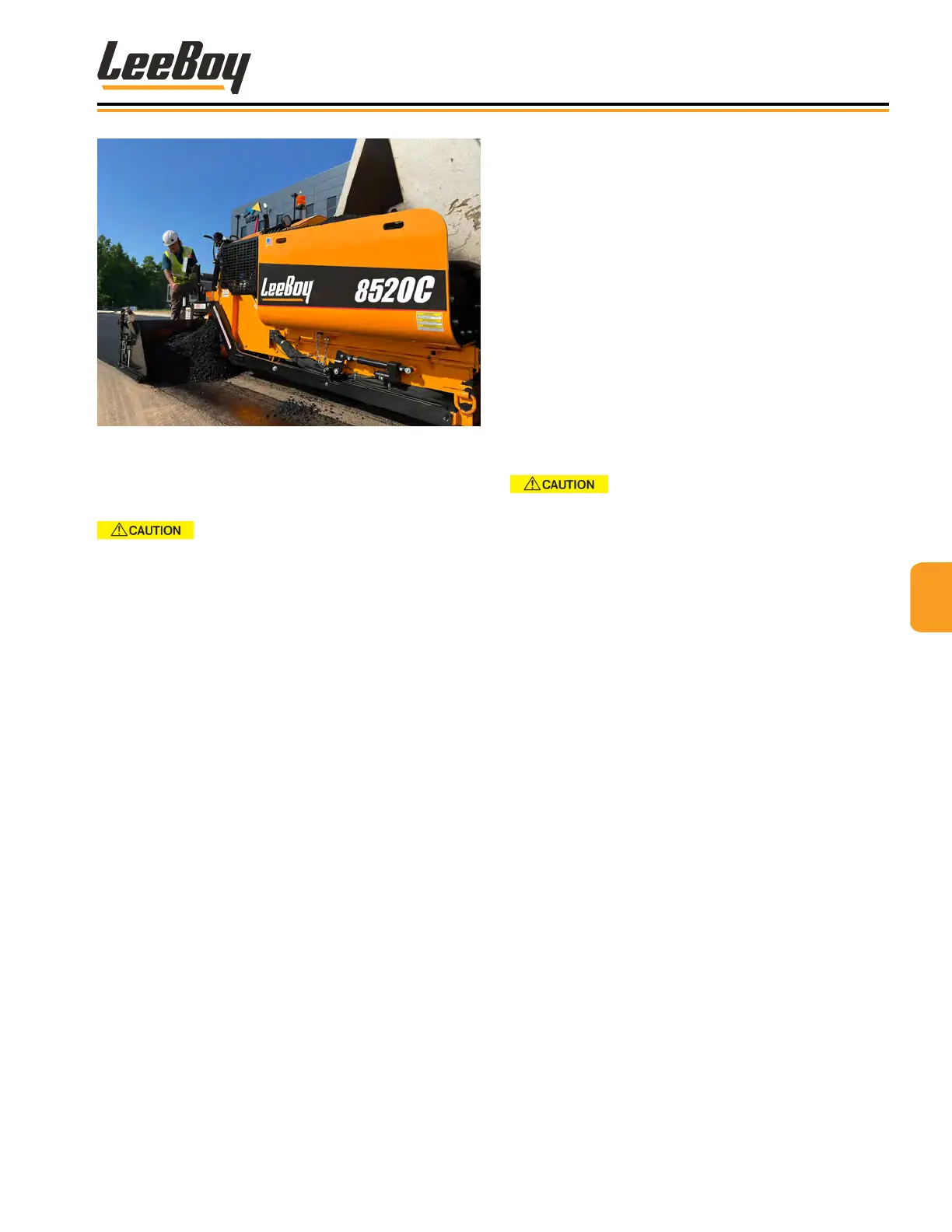

Figure 4-76. Paving a Road

Basic PavingBasic Paving

Avoid low limbs, power lines, and

other objects that can endanger crew or paver.

1. Position paver at the starting point for the mat.

2. Open Under Auger Material Cut-Offs.

3. Adjust screed as needed.

4. Adjust truck push rollers to the appropriate height

needed for asphalt truck. (Figure 4-74) Use truck

hitch controls if equipped with this option. (Page

4-39 )

5. Open hopper wings to accept asphalt from the

material truck.

NOTE: Allow only a partial load of asphalt to enter the

hopper when rst starting to pave.

6. Turn the left and right conveyor switches to the

AUTO position.

7. When the material begins to discharge from under

the screed, set the screed lift switch to the FLOAT

position.

8. If paving a width more than eight feet, turn the left

and right auger switches to AUTO to control the

material height at the endgate. (Augers aren’t

needed when paving a basic eight-foot pull.)

9. When the material starts moving into the sonic

range, the sonic auger will automatically regulate

the auger operation.

NOTE: The material height must be set to the highest

point when the endgates are closed. When

the endgates are open, the material height will

lower to prevent material from pushing in front

of the endgates.

10. Begin paving, moving slowly at rst to adjust the

screed if needed.

11. Make a paving pass until the asphalt level in the

hopper is low.

Never back up with cut-offs open.

NOTE: To prevent excessive handwork, set the

left and right conveyor switches to the OFF

position and set both cut-off switches to the

CLOSE position about three feet from the end

of the pull to prevent excessive handwork.

12. Return paver back to starting position to begin the

next pull.

13. Position and set the screed endgate on the joint

side back to “0” feet, or ush with bottom of the

screed.

14. Repeat these steps as you continue to pave.

Loading...

Loading...