5-38 LeeBoy 8520C Conveyor Paver

Maintenance

Front IdlerFront Idler

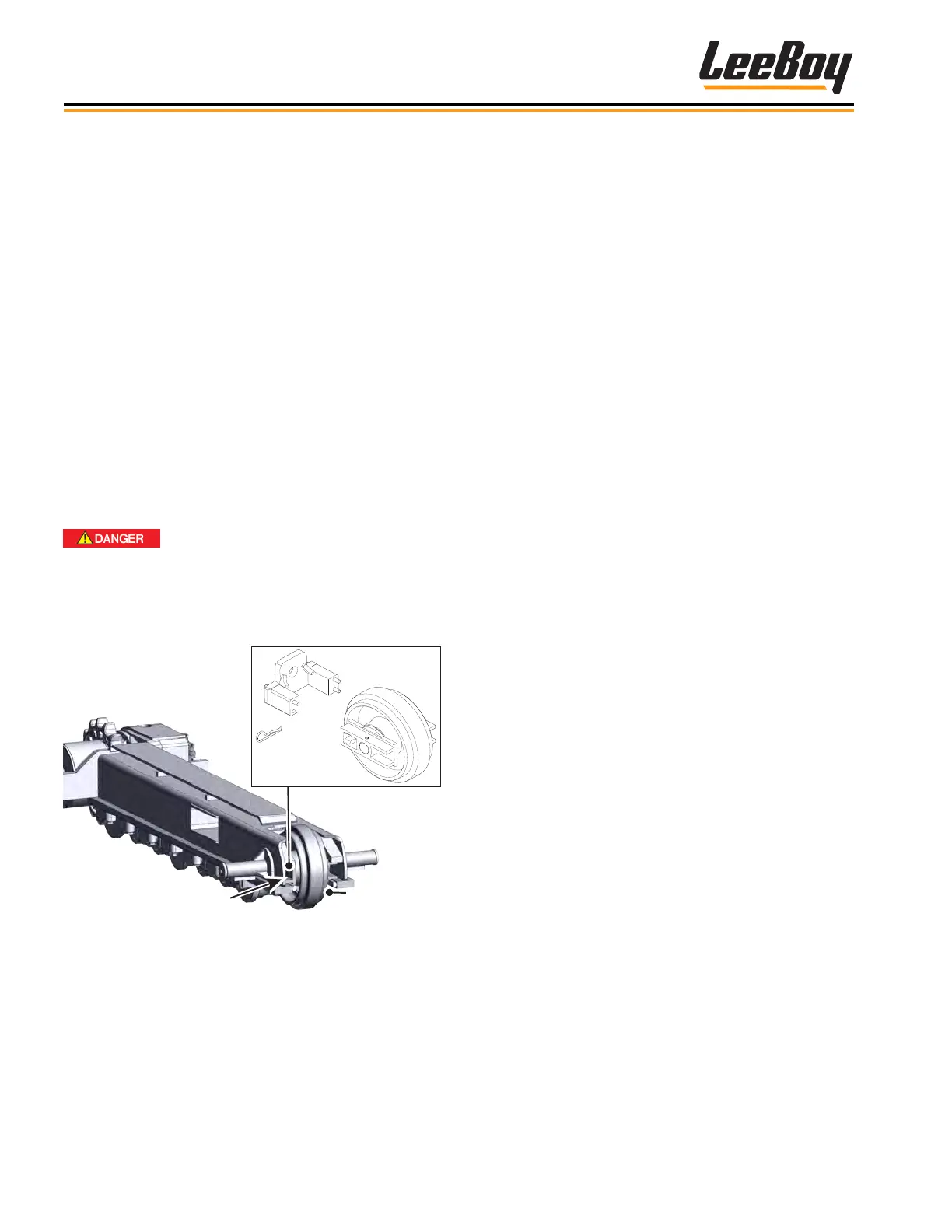

Follow this procedure for replacing the front idler

(Figure 5-46):

1. Raise conveyor and insert safety prop. (Pages 5-6

and 5-6)

2. Locate track tension manifold and back the relief

cartridge out of the aluminum block about three

turns until you hear the tension pressure release.

(Page 5-50)

NOTE: Perform this additional step for poly or steel

tracks only: Rotate the track so the master

pin is at the rear bottom of the front idler and

back up the paver until the track clears the

front idler.

3. Jack up the paver at least two feet off the ground

for enough clearance under the undercarriage

to perform this procedure and stabilize with jack

stands or safety blocks.

Crush hazard! Always use safety

blocks or jack stands when working under the paver

to prevent serious injury or even death.

4. Remove the clevis pin from the cylinder rod and

idler bracket. Idler will slide out.

Clevis Pin

Front Idler

Clevis Pin

Front Idler

Figure 5-46. Remove Clevis Pin to Release Front

Idler

5. Remove the idler bracket and bolt to the new idler.

6. Install new idler, ensuring cylinder and clevis pin are

aligned properly.

7. Lower sprocket back down toward the track chain,

ensuring the sprocket is about one (1) inch from the

chain.

Perform these additional steps for poly or steel

tracks only:

8. Check that the track chain is full seated with the

drive sprocket and rollers are aligned with chain

center.

9. Tighten the tension relief.

10. Lower paver to ground, remove jack and start

machine. Track tensions will automatically adjust

when the machine is started.

11. Ensure the track chain remains fully seated with the

drive sprocket and rollers still aligned with the chain

center.

Track Tension CylinderTrack Tension Cylinder

1. Follow Steps 1 - 4 in the previous section. The track

tension cylinder is located behind the front idler.

(Figure 5-45 on Page 5-37)

2. Pull the track tension cylinder toward the front to

remove the hose from the bottom of the cylinder.

3. Repack the seal kit or replace cylinder if worn, and

reinstall.

4. Install idler, ensuring cylinder and clip pin are

aligned properly.

NOTE: If equipped with poly or steel tracks, follow

Steps 8 - 11 above.

Loading...

Loading...