5555

LeeBoy 8520C Conveyor Paver 5-51

Maintenance

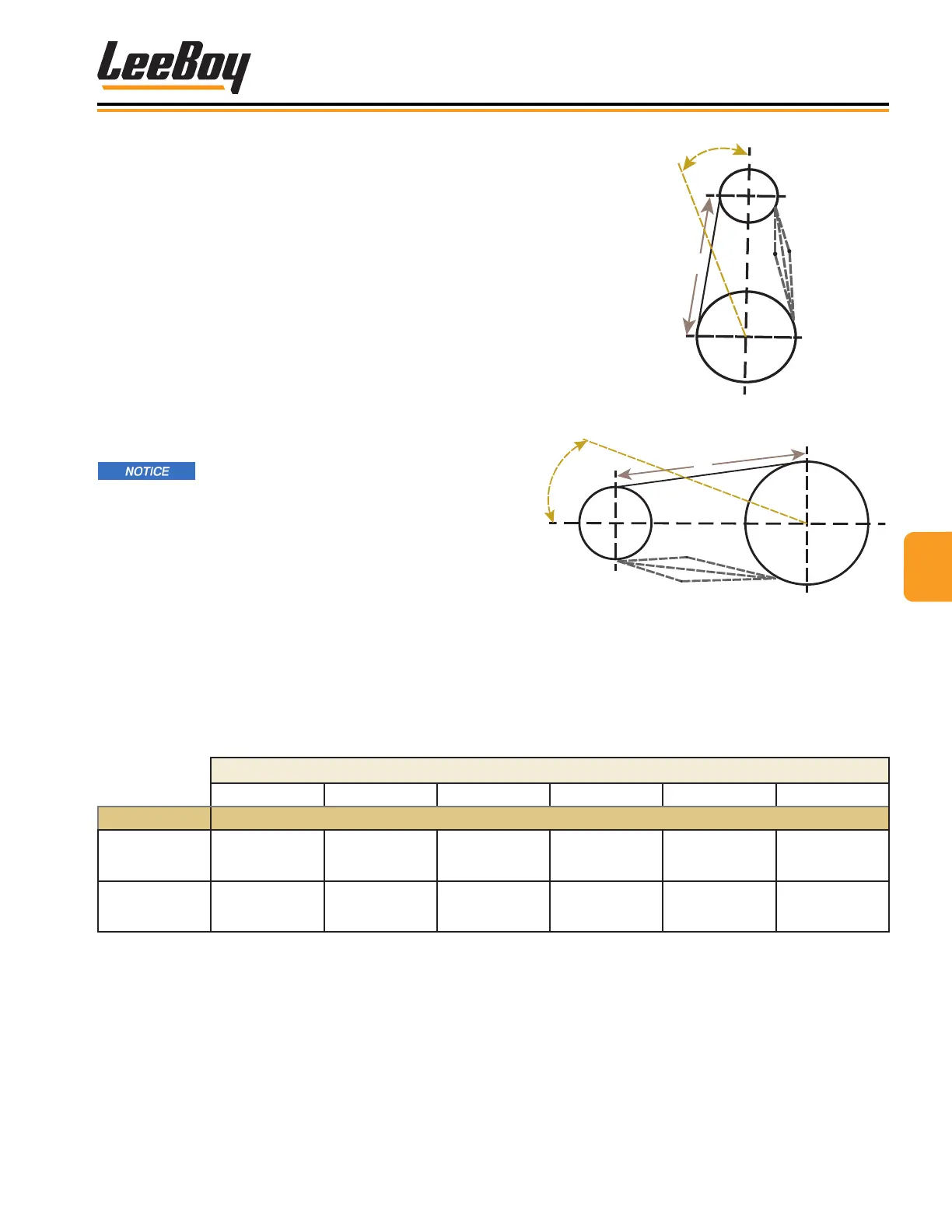

TL

45º

Horizontal to 45° Chain Tension

45° to Vertical

Chain Tension

S

S

45º

TL

S - SLACK

TL - TANGENT LENGTH

Figure 5-67. Chain Slack Adjustment for Proper

Tension

Auger and Conveyor Chain Auger and Conveyor Chain

Tension AdjustmentTension Adjustment

The auger and conveyor chains need periodic adjust-

ment. Generally, the slack of a roller chain should be

on the lower side. (Figure 5-67) Adequate slack (S) is

about four (4) percent of the span for normal drives, but

the slack should be about two (2) percent of the span for

the auger chains:

• Vertical drive or close to vertical drive.

• Center distance between two shafts is greater than

three (3) feet.

• Chain is operated under heavy load and high

frequency of on and off drive.

• Direction of the drive is often changed.

Auger and conveyor chains must have

a slack of 1/4 to 3/8 inches. To measure deection,

exert 40 - 60 pounds of force to chain in either

direction.

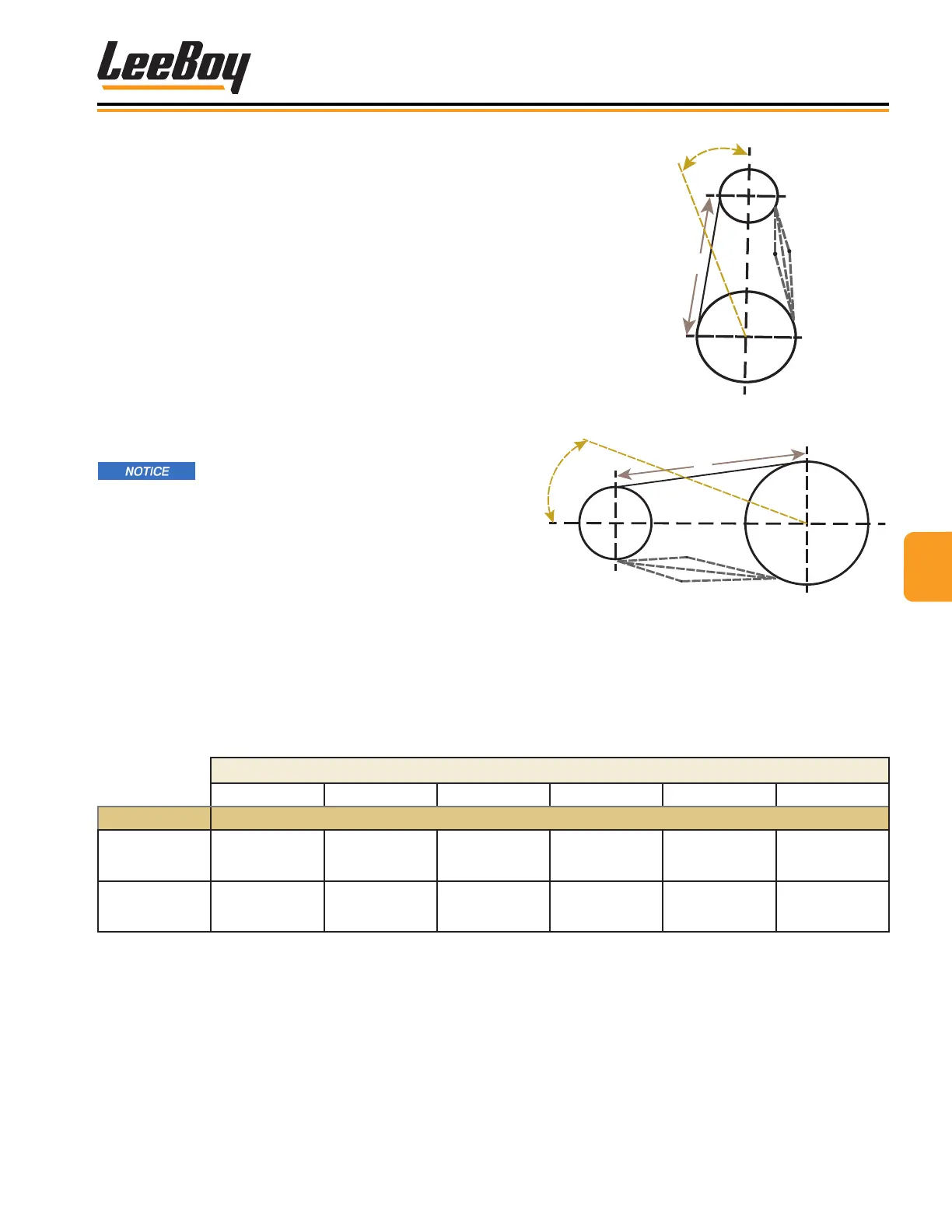

Tangent Length (TL) Between Sprockets in Inches (Centimeters)

10 (25) 20 (51) 30 (76) 50 (127) 70 (178) 100 (254)

Slack Length Between Sprockets in Inches (Millimeters)

Horizontal

To 45°

0.4 - 0.6

(10 - 15)

0.8 - 1.2

(20 - 30)

1.2 - 1.8

(30 - 46)

2.0 - 3.0

(51 - 76)

2.8 - 4.2

(71 - 107)

4.0 - 6.0

(102 - 152)

45° To

Vertical

0.2 - 0.3

(5 - 8)

0.4 - 0.6

(10 - 15)

0.6 - 0.9

(15 - 23)

1.0 - 1.5

(25 - 38)

1.4 - 2.1

(36 - 53)

2.0 - 3.0

(51 - 76)

REQUIRED MID-SPAN MOVEMENTREQUIRED MID-SPAN MOVEMENT

Loading...

Loading...