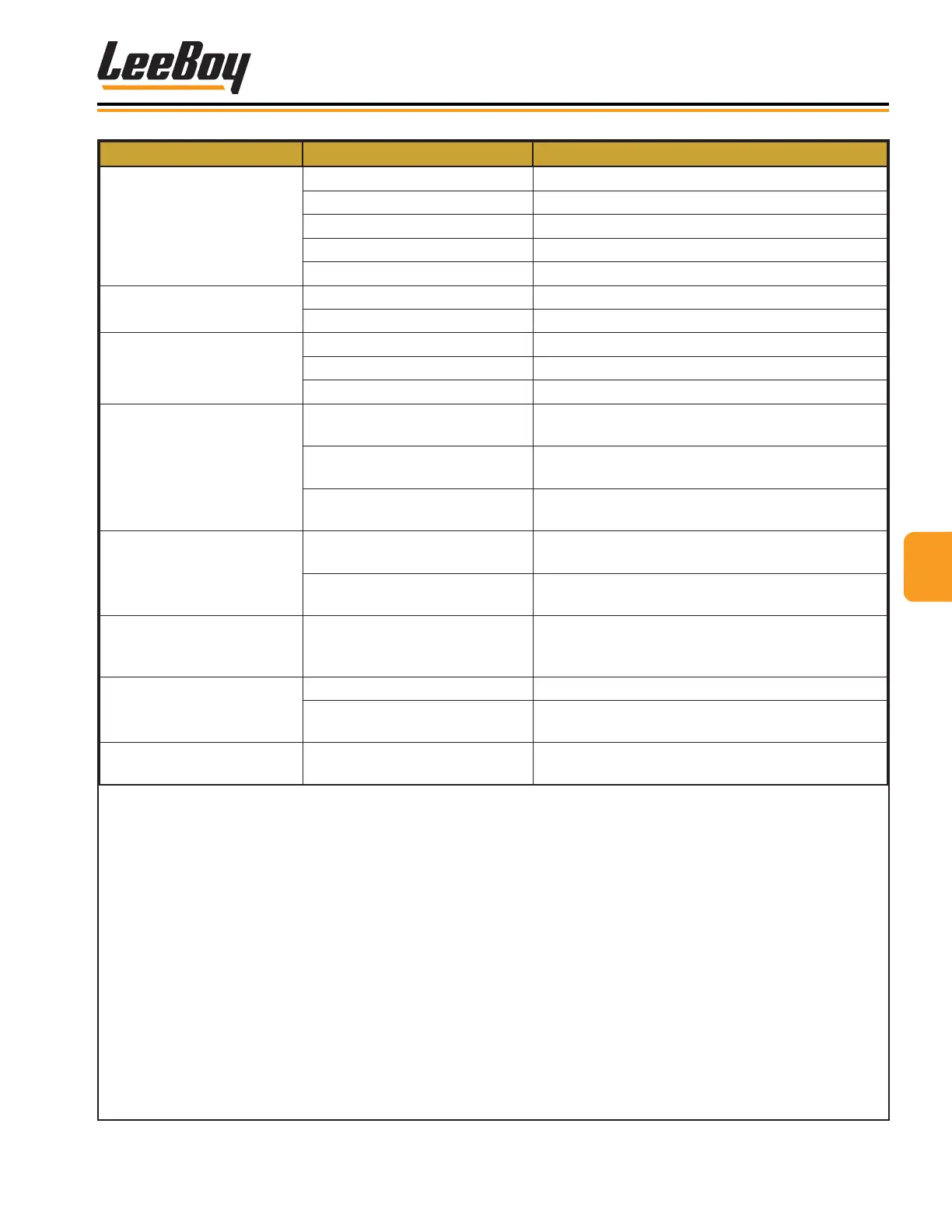

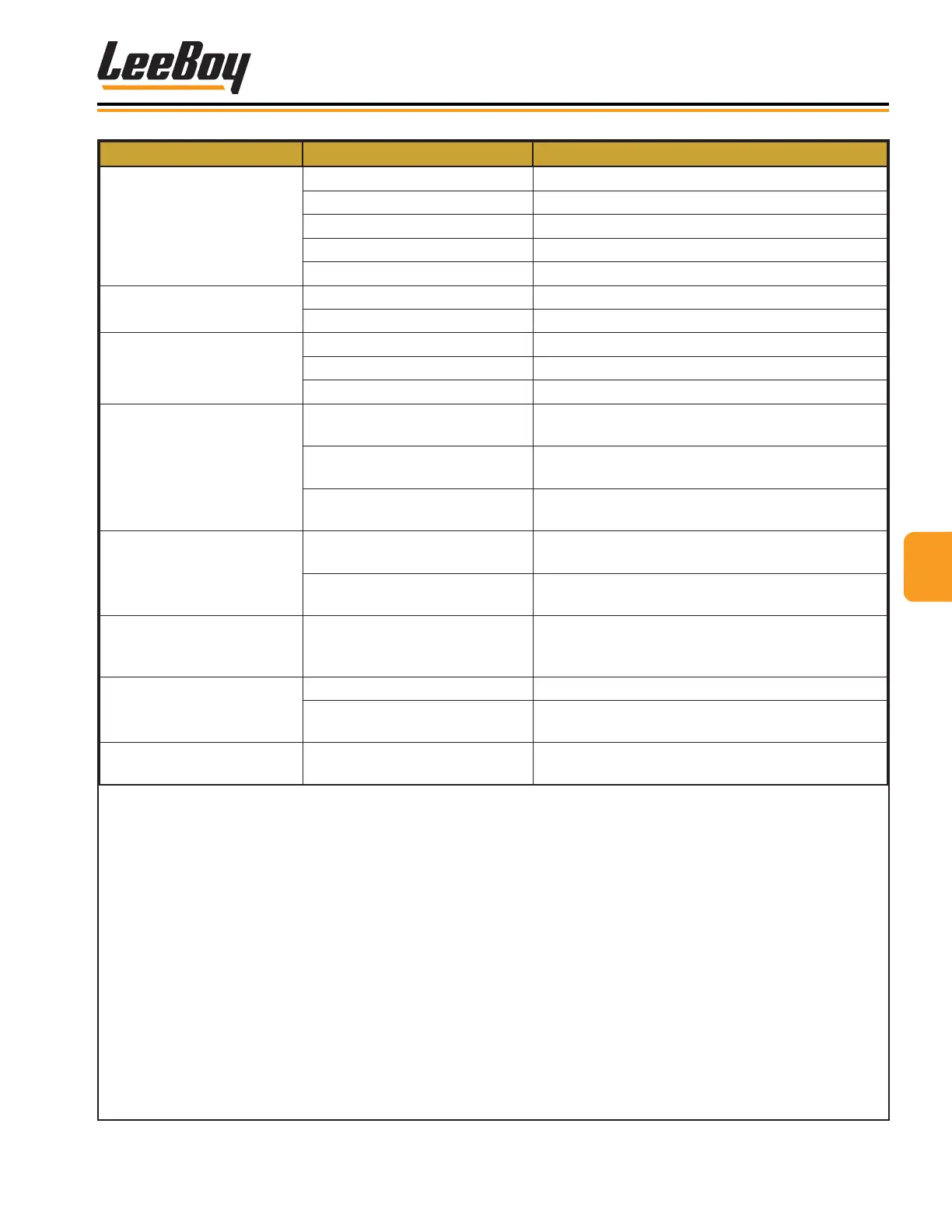

SYMPTOM CAUSE REMEDY

Feeder does not work on

one or both sides.

Defective switch. Adjust or replace switch.

Solenoid defective. Replace solenoid.

Feeder drive chain broken. Adjust or repair chain.

Defective conveyor motor. Replace motor.

Rear conveyor shaft broken. Replace conveyor shaft.

Feeder ight bars don’t

function properly.

Flight chains too loose. Adjust.

Feeder drive chain too loose. Adjust.

Loss of power to drives.

Relief out of adjustment. Check pressure and adjust if needed.

Piston groups worn. Replace.

No charge pressure. Check that charge pressure is 320 PSI.

Electric screed heating

system will not operate.

Control box power switch not in

ON position.

Ensure that the screed operator control box

Power switch is ON.

Breakers are in a “tripped”

position.

Ensure all element breakers are in the proper set

position.

Generator malfunction.

Check voltage and frequency. Rebuild or replace

if needed.

Only part of the electric

screed heats.

Screed section not plugged into

bottom of the control box.

Replug.

Element breakers for screed

section in a “tripped” condition.

Ensure the element breakers for that screed sec-

tion are not “tripped.”

Electric screed heat system

doesn’t start, or starts and

doesn’t run very long.

Heating system timed out. Check timing relay. Adjust or replace.

Electric Screed is heating,

but never gets hot enough

to pave.

Elements improperly clamped. Ensure elements are clamped properly.

Generator malfunction.

Ensure generator is “spinning.” Check voltage and

frequency. Rebuild or replace if needed.

Elements have been tested,

but the breaker still trips.

Faulty element wiring. Inspect and test element wiring.

5555

LeeBoy 8520C Conveyor Paver 5-55

Maintenance

Loading...

Loading...