Group 6 Operation – description of the device Page 70

Release 3.00 Leibinger-Jet 2 se

6.5.5.3 Nozzle plate

The jet is made up of a precious stone with the actual jet bore. The precious stone is

held in a steel plate in order to enable simple replacement and adjustment of the ink jet.

The diameter of the bore is between 40-70 micrometers depending on the design of the

jet.

An O-ring is secured to the nozzle plate with a clamping plate and two slotted screws to

seal the gutter when the jet is closed. The jet is pressed against the spray body with a

fixing screw. This produces a liquid-tight and yet movable connection (see illustration

spray body with oscillator).

6.5.5.4 Nozzle seal with gutter (Nozzle closure)

The nozzle seal prevents the drying of the ink in the jet, the gutter (catcher pipe) and the

suction pump during operational standstill.

This is achieved with an electrical spindle drive which moves the gutter in the direction of

the jet from the writing position to the jet and in the reverse direction when switching on.

The nozzle seal is a unit which can be completely replaced in case of need.

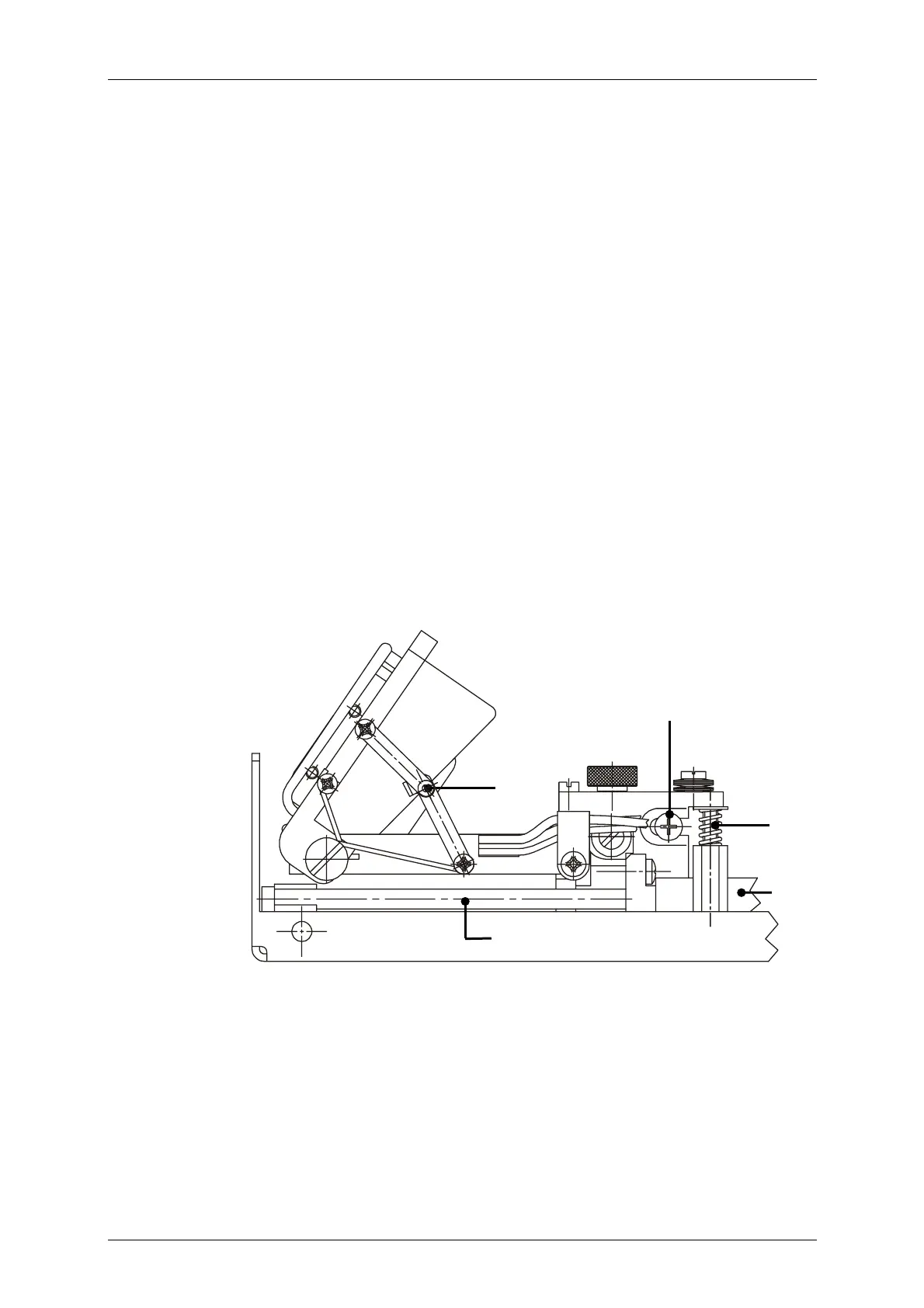

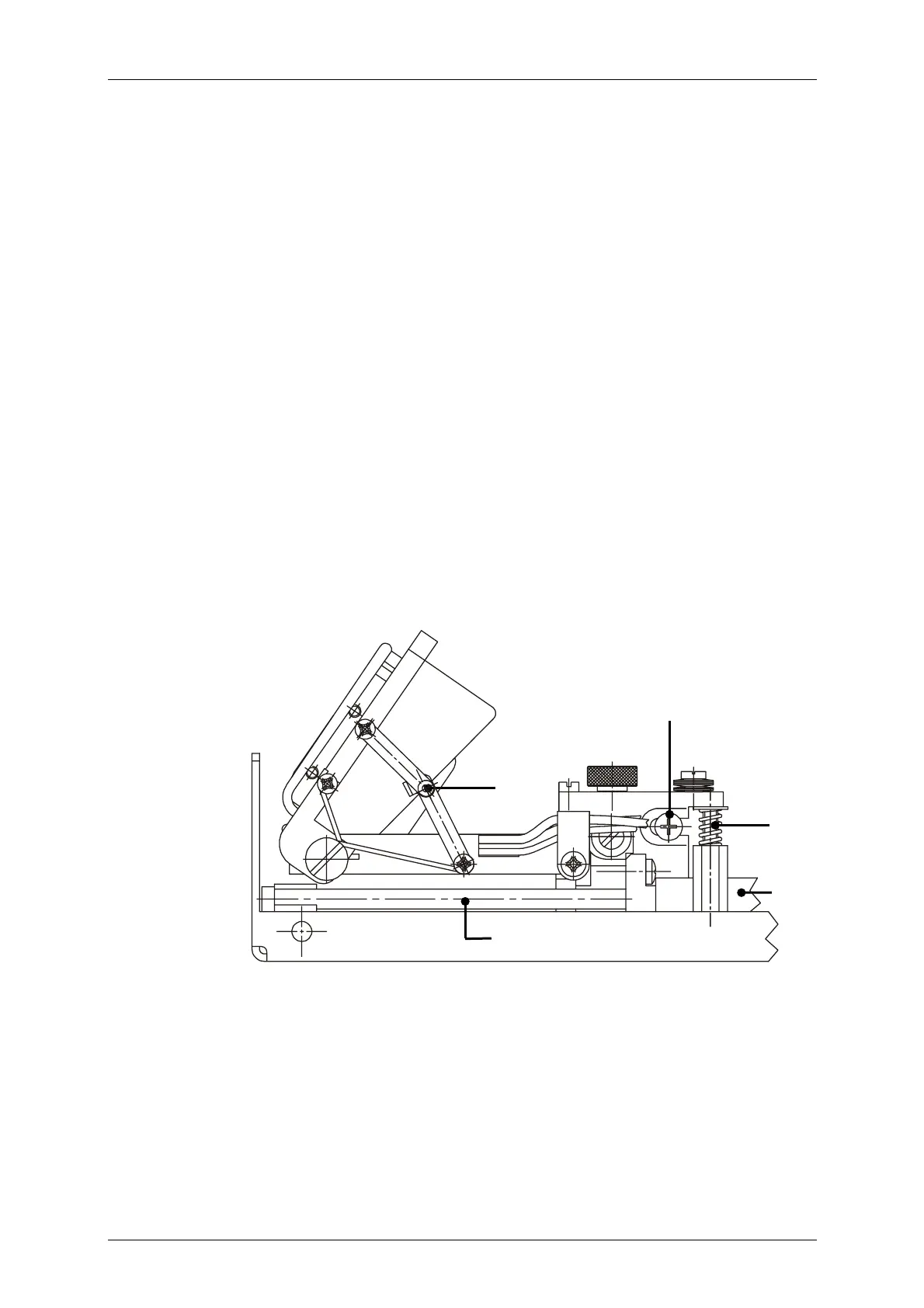

Figure 39

Nozzle seal 1 – Drive motor

2 – Guide shaft

3 – Toggle lever for arresting for cleaning purposes

4 – Jet (nozzle) adjustment screw (left/right)

5 – Jet (nozzle) adjustment screw (up/down)

3

5

1

2

4

Loading...

Loading...