7 CiA402 device profile

7.10 Cyclic sync torque mode (cst)

235

Lenze · i700 servo inverter · reference manual · DMS 3.0 EN · 06/2016 · TD06

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

0x6073 | 0x6873 - Max current

Tip!

More torque characteristics can be found on the Internet:

Maximum current (maximum overload current of the device)

•100% ≡ rated motor current (0x6075

or 0x6875 for axis B)

• This parameter serves to limit the inverter output current.

• The value to be set here results from the maximum torque required for the process and the connected motor.

The value is calculated according to the following rule of thumb:

• For synchronous motors (SM):

Axis A: 0x6073 [%] = M

max_process

[Nm] / 0x6076 [Nm] * 100

Axis B: 0x6873 [%] = M

max_process

[Nm] / 0x6876 [Nm] * 100

• For asynchronous motors (ASM):

Axis A: 0x6073 [%] = M

max_process

[Nm] / 0x6076 [Nm] * 115

Axis B: 0x6873 [%] = M

max_process

[Nm] / 0x6876 [Nm] * 115

• For both motor types:

Axis A: 0x6072

[%] = M

max_process

[Nm] / 0x6076 [Nm] * 100

Axis B: 0x6872

[%] = M

max_process

[Nm] / 0x6876 [Nm] * 100

• Depending on the motor frame size, the Lenze setting of 0x6073 (or 0x6873 for axis B) and 0x6072

(or 0x6872

for axis B) serves to achieve a rated current of 150 % in case of synchronous motors and a rated current of 130 %

in case of asynchronous motors. If the process (application) needs torques above these limits, these two

parameters have to be set accordingly based on the motor data.

• If a value is set here which, multiplied by the rated motor current (0x6075

or 0x6875 for axis B) leads to a higher

current value than the maximum device current, the value is limited device-internally to a maximum device

current / rated motor current of 100 % * and output as warning in the logbook. The value set here, however, is

not changed.

Note!

This parameter is not identical to the ultimate motor current I

ULT

(0x2D46:1 or 0x3546:1 for axis B!

• The ultimate motor current is a limit value for synchronous motors in order to protect their magnets.

• The value to be set here should always be considerably below the ultimate motor current!

Setting range (min. value | unit | max. value) Lenze setting

0.0 % 3276.7 150.0 %

Write access CINH OSC P RX TX Scaling: 1/10 UNSIGNED_16

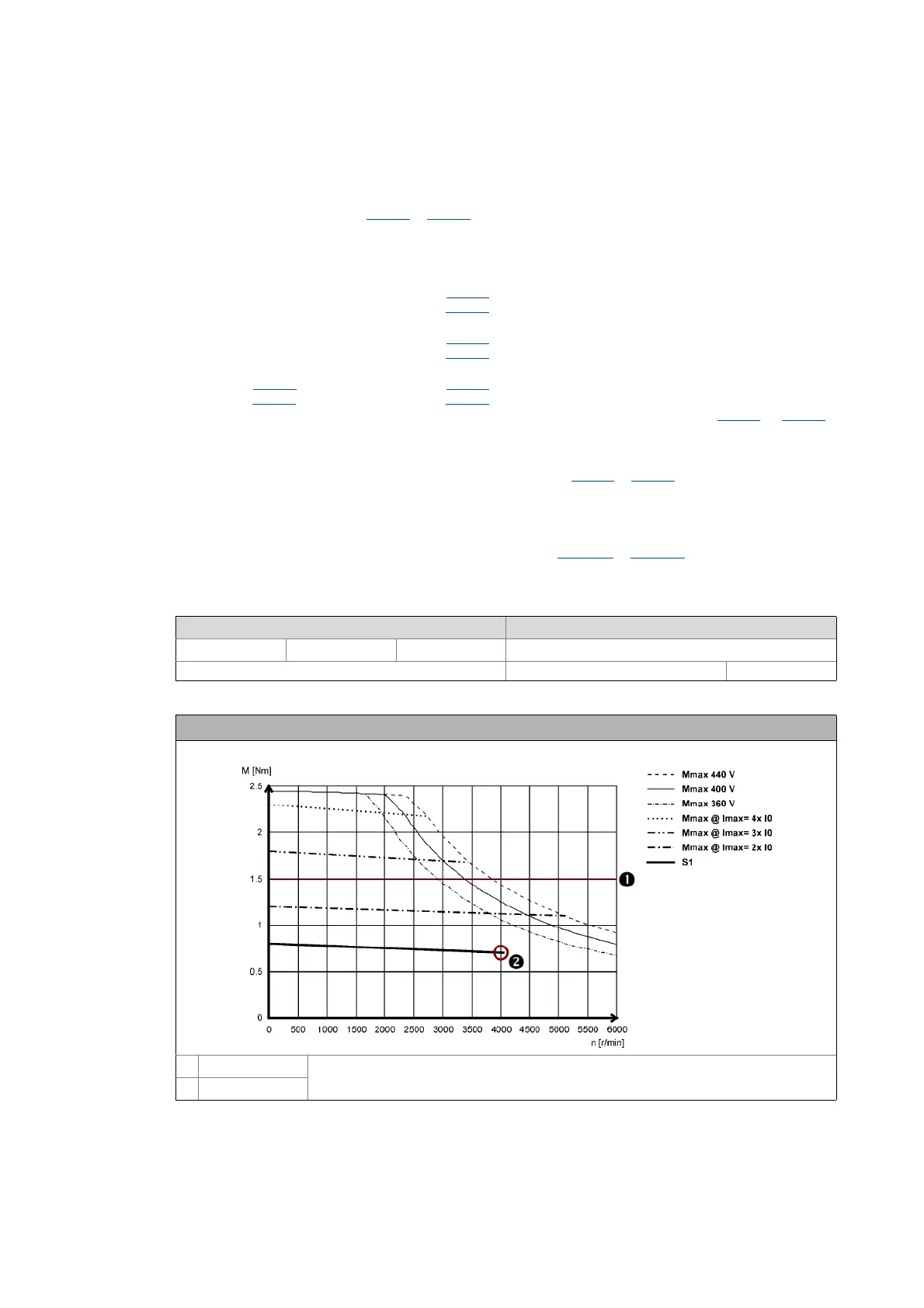

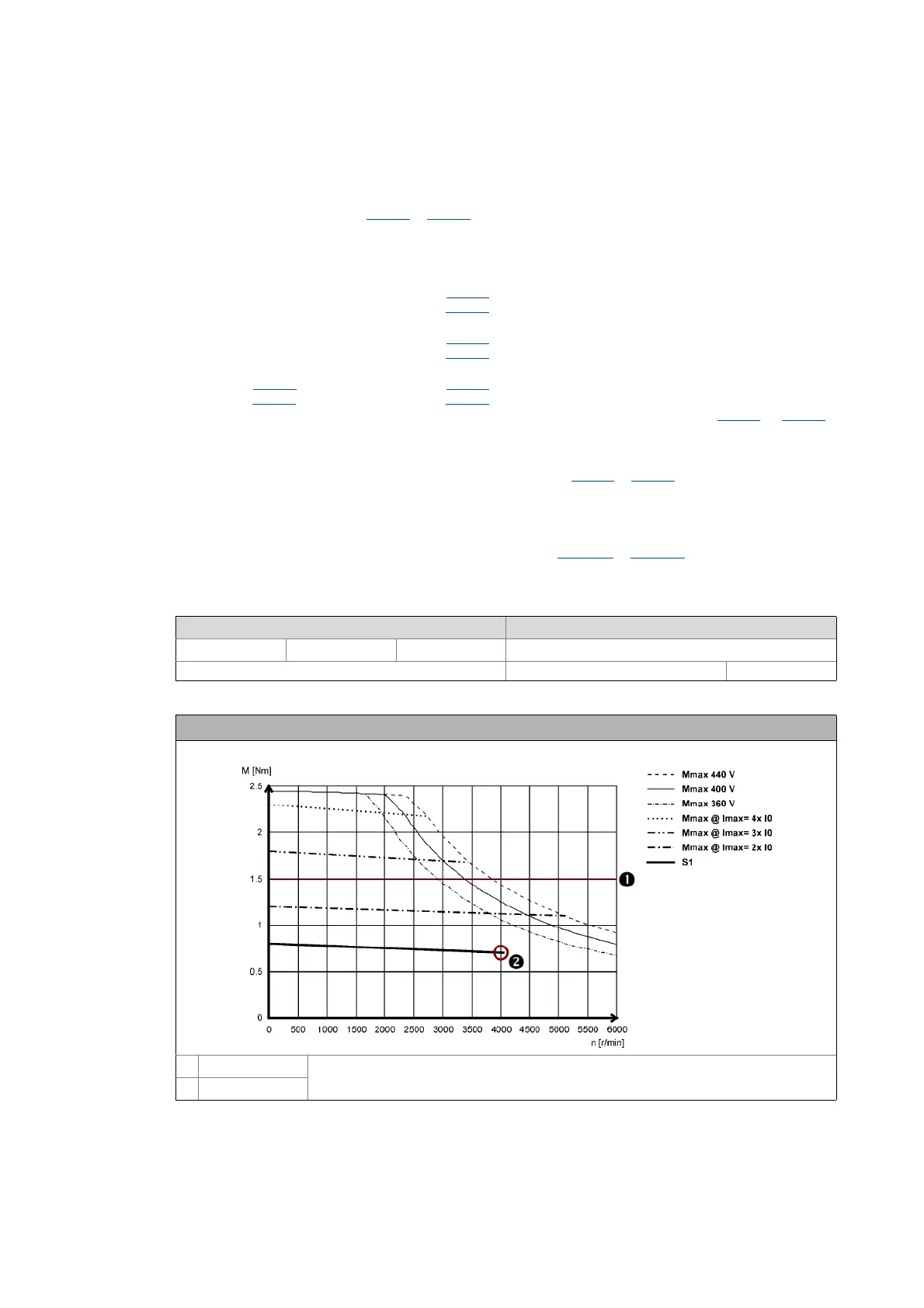

Example calculation based on the torque characteristics for MCS06C41 Lenze motor

The data apply to a mains voltage 3 x 400 V

M

max_process

0x6073 = M

max_process

/ M

rated_motor

* 100 % = 1.5 Nm / 0.7 Nm * 100 % = 215 %

M

rated_motor

Loading...

Loading...