LS SERIES SERVICE MANUAL

ISSUE 4.0 MECHANICAL ASSEMBLIES 6

8.9 Lower Eye End Alignment

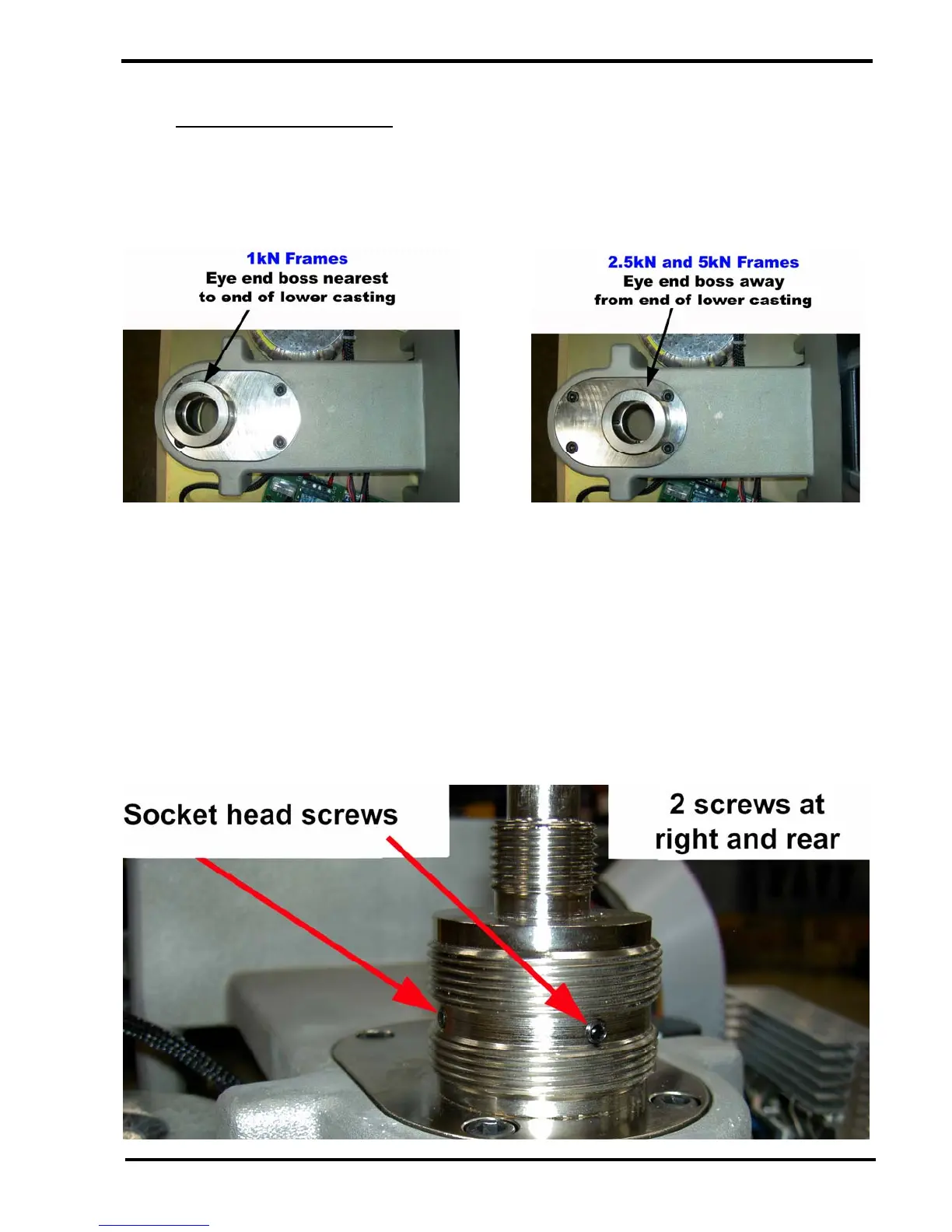

The Lower Eye End is fitted to a mounting boss that is attached to the lower casting. For

information, the 1kN frames have a 180mm throat depth but the higher force 2.5kN and 5kN

machines have a 140mm throat depth. The throat depth is selected during production by fitting

the eye end mounting boss in the required orientation as shown below.

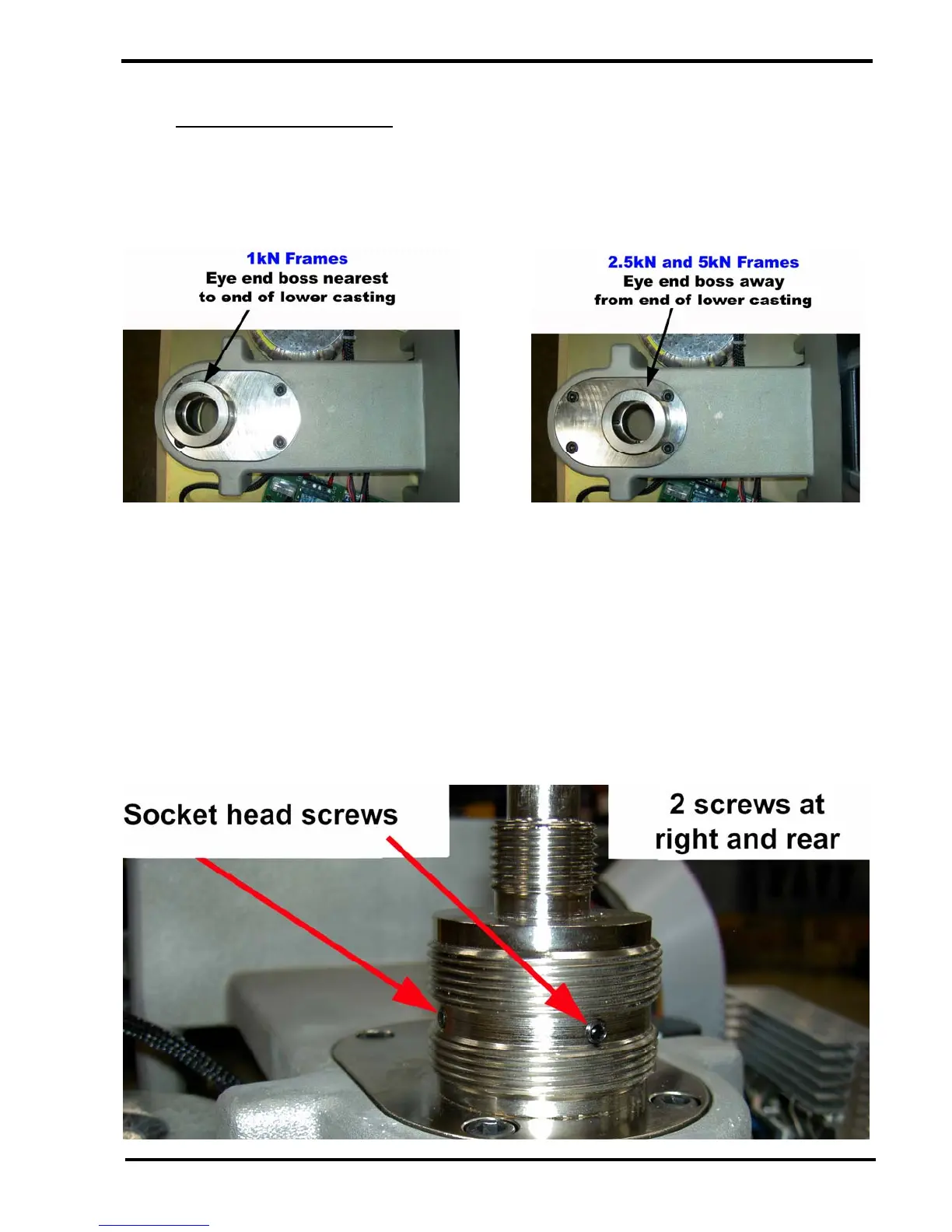

To prevent any side loading of a sample, the lower eye end should be accurately aligned to the

loadcell eye end. The diameter of the hole in the lower eye end boss is larger than the eye end

shaft and the lower eye end boss has 4 horizontal socket head screws to provide horizontal

adjustment.

Remove the eye end locking ring then carefully lower the crosshead until the loadcell eye end is

just above the top of the lower eye end then check the alignment. If adjustment is required,

loosen the relevant socket head alignment screws then re-align the lower eye end. When the

eye end alignment is correct, rotate each socket head screw clockwise until it JUST touches the

eye end shaft. Check that the lower eye end can be rotated by hand. If it cannot be rotated,

then the alignment screws are too tight so loosen the front socket head screw and the right

hand socket head screw until the eye end can just be rotated by hand.

Loading...

Loading...