LS SERIES SERVICE MANUAL

ISSUE 4.0 MECHANICAL ASSEMBLIES 9

8.12 Replacing the Loadcell Loom

The loadcell loom is attached to the moving crosshead and after prolonged service, the

conductors in the loom may start to break and the load reading will jump or the machine may

not correctly recognise the loadcell value. If these symptoms occur, the loom (09/1034) will

have to be replaced.

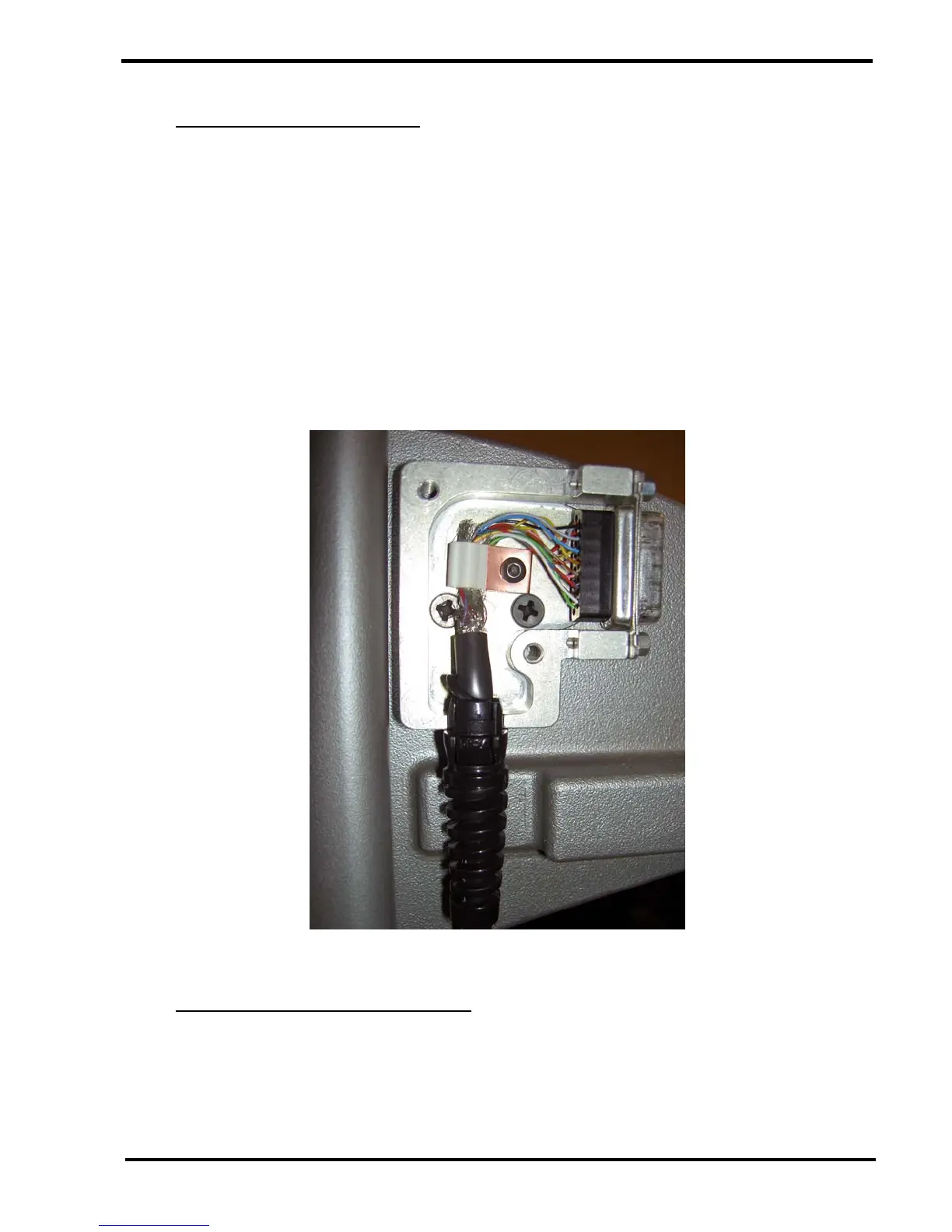

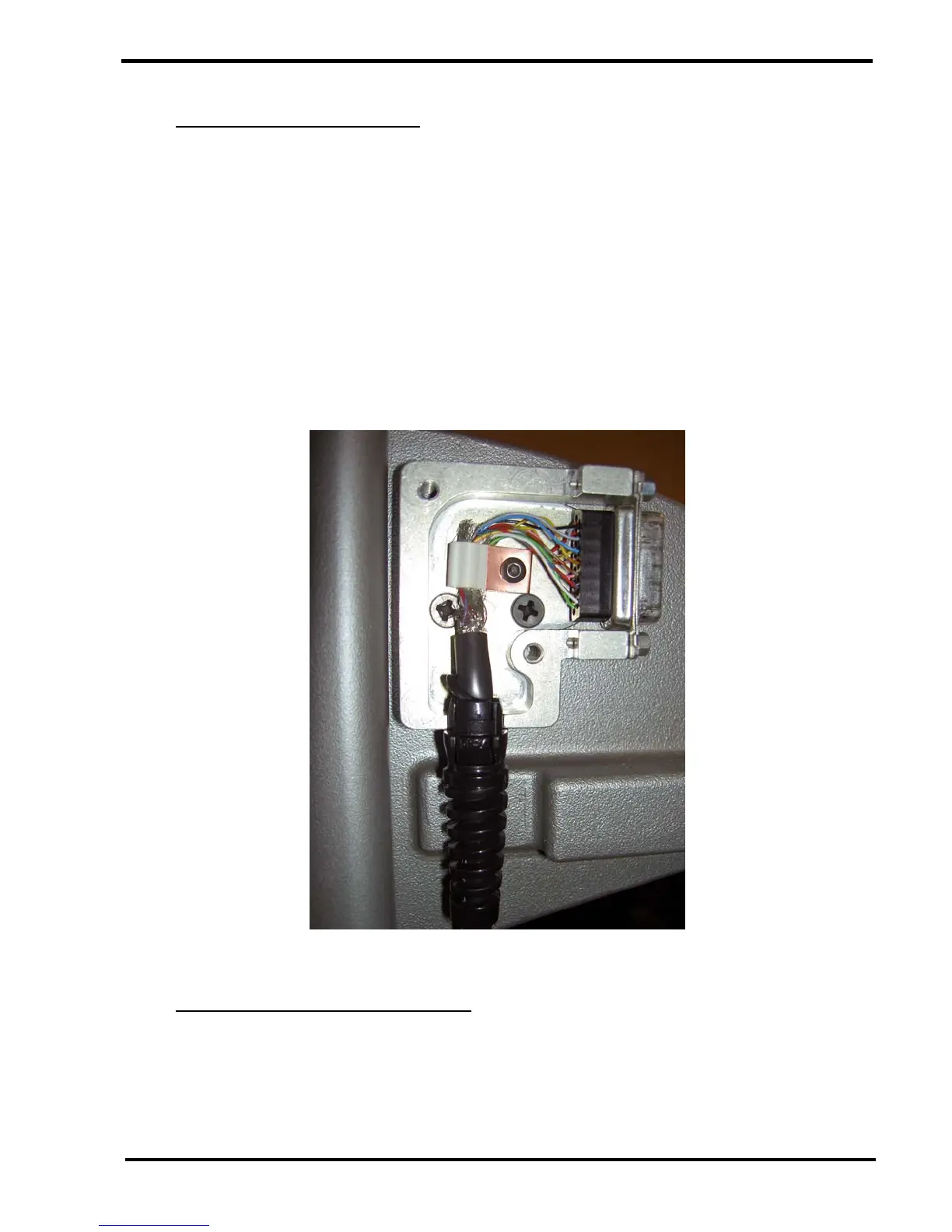

Unscrew and remove the 2 off M4 socket head screws then remove the outer cover from the

loadcell connector box on the moving crosshead. Note that the 15-way D connector will remain

fixed to the crosshead. Unscrew the 2 pillars securing the 15-way D connector to the loadcell

connector box. Unscrew and remove the "P" clip securing the cable to the loadcell connector

box then remove the cable assembly.

When refitting the new cable, ensure that the cable screen is correctly bonded to the inside of

the loadcell connector box to maintain EMC compliance.

8.13 Removing the Mechanical Assembly

Removing the mechanical assembly will give access to the leadscrew and linear rail.

Note that the Mechanical Assembly does not have to be removed for routine maintenance.

Loading...

Loading...