LS SERIES SERVICE MANUAL

ISSUE 4.0 MECHANICAL ASSEMBLIES 7

8.10 Adjusting the Drive Belt Tension

Remove the lower cover then check the condition of the drive belt. If the belt is worn, indicated by

signs of fraying or belt dust in the base of the machine, it is recommended that it be replaced.

Check the tension by twisting the belt half way between the motor and leadscrew pulleys. It should

be just possible to twist the belt through 90 degrees. If the tension is not correct, follow the

procedure below: -

Remove all plugs and cables from the rear connectors.

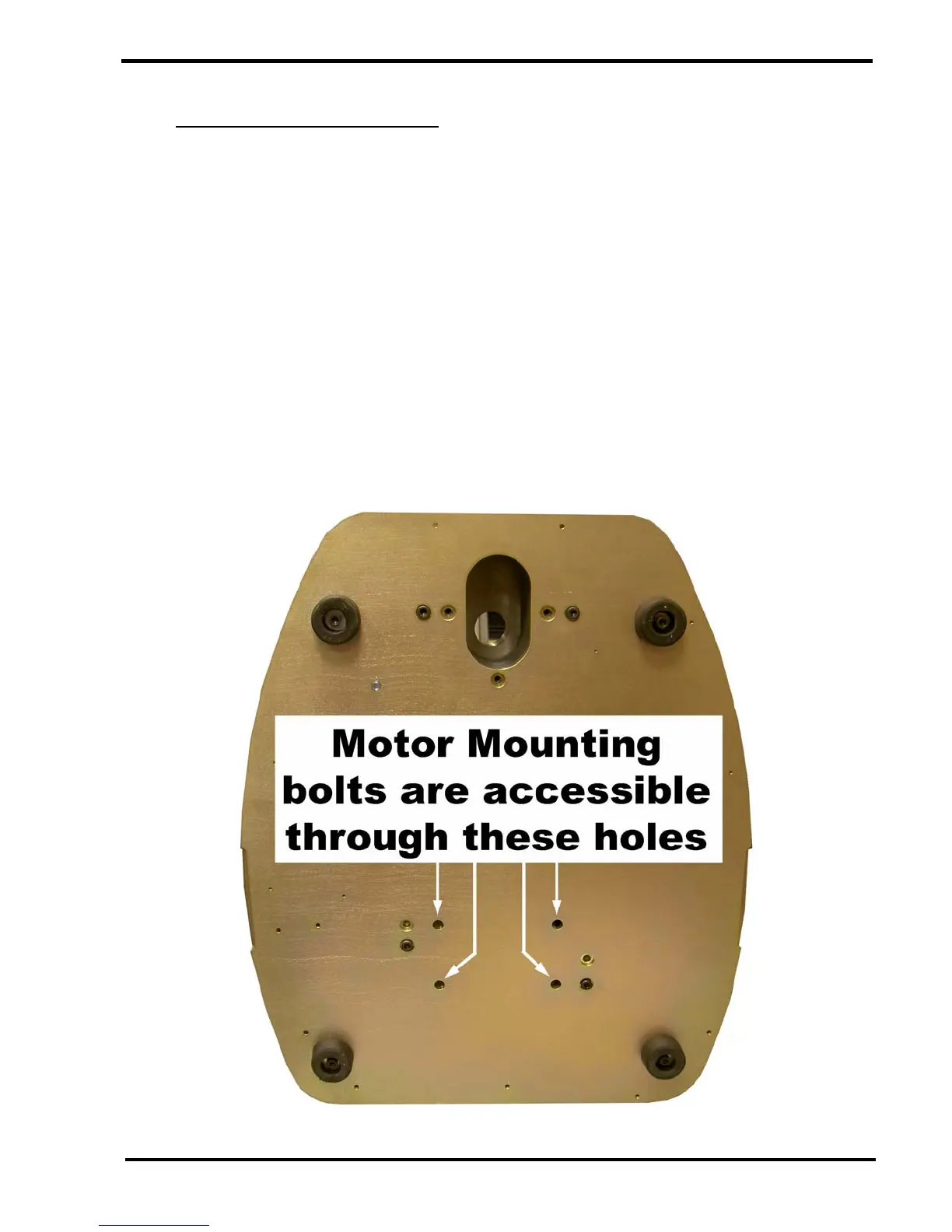

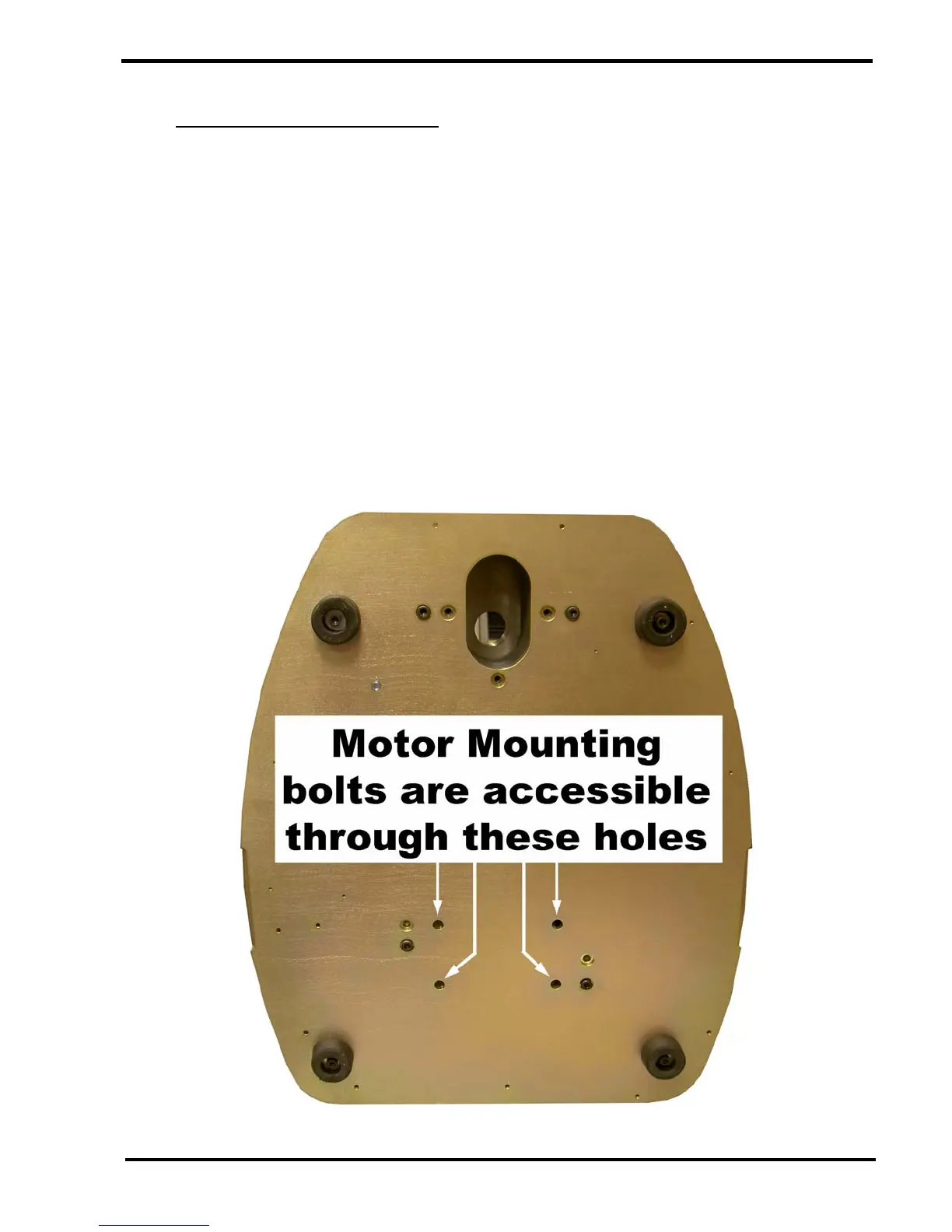

Lay the machine over onto its back and support the top and bottom ends of the vertical column

using 2 wooden blocks. A suitable thickness for each block is 150mm (6 inches). Ensure that the

weight of the machine is NOT applied to any of the rear connectors.

Using a long hexagonal key, loosen the 4 off 6mm socket head screws that secure the motor

mounting plate to the lower casting. Slide the motor assembly to adjust the belt tension then

retighten the 4 fixing screws. Note that the drive belt can be replaced by pulling it away from the

pulleys.

Loading...

Loading...