LS SERIES SERVICE MANUAL

ISSUE 4.0 FULL CONTROL CONSOLE DIAGNOSTICS 7

12.6 Loadcell Calibration

Note that the loadcell can ONLY be calibrated if an accurate reference load is available.

Ensure that the Safe-Line button is pressed so that the yellow lamp is not lit.

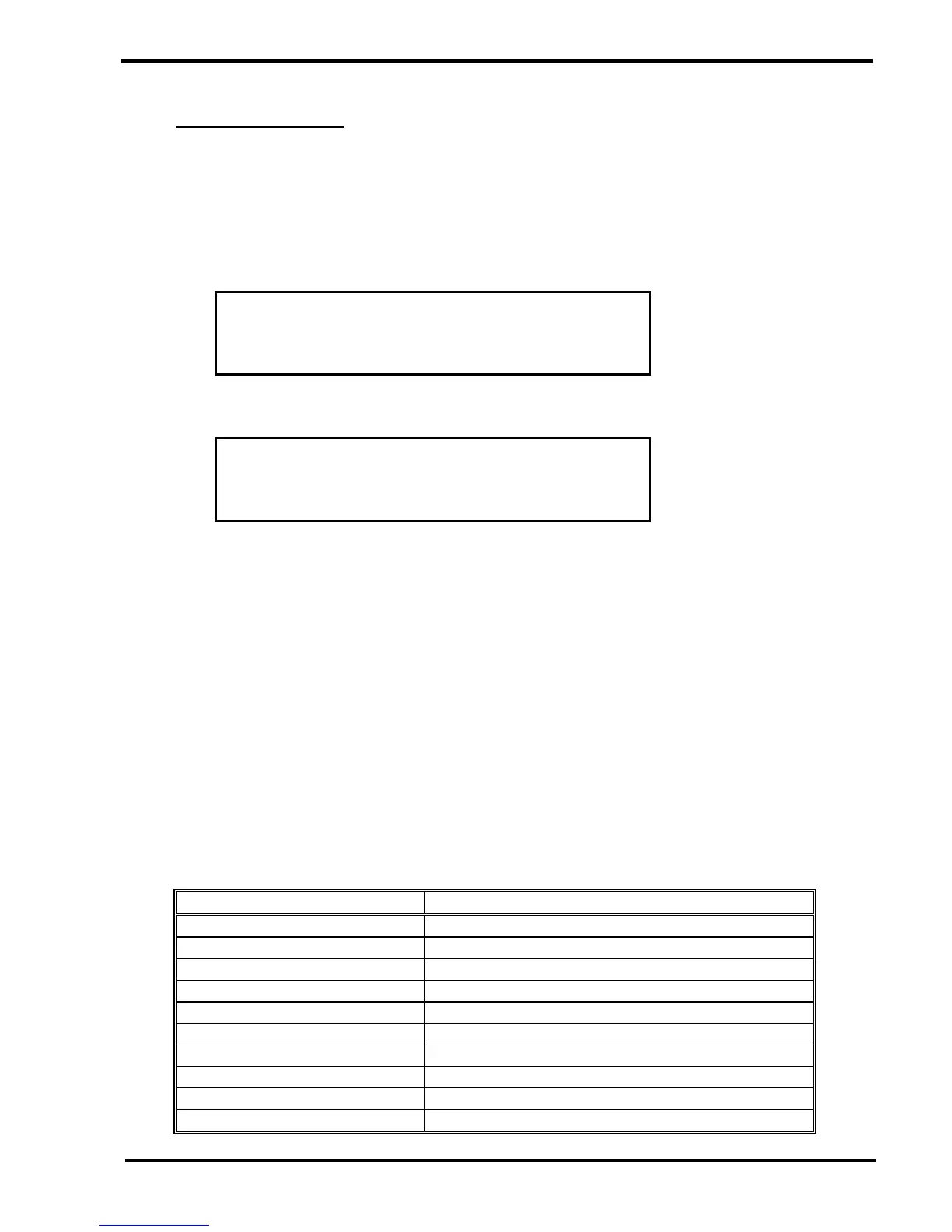

1 Press the key under LOADCELL to display the "Calibrate Loadcell" screen.

Calibrate Load Cell

Serial

Number Size Calibrate View

XXXX 1kN Or Verify Points

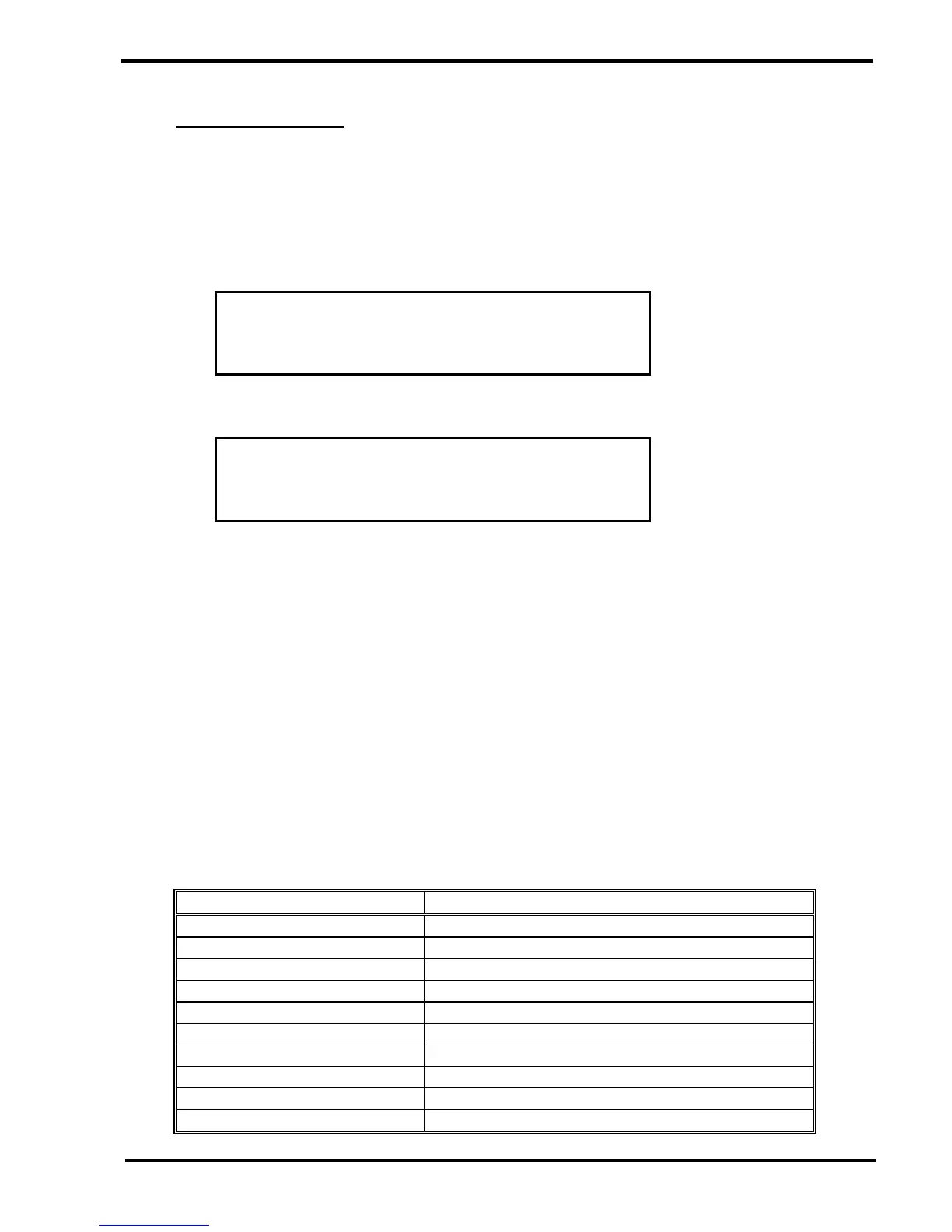

2 Press the key under CALIBRATE OR VERIFY to display the screen shown below: -

Serial Number XXXXX Size XkN

Measured Load XXXXX N

Clear Cal Cal Direction

Points Point Tension Up

3 Attach the calibration device to the machine ensuring that no load is applied to the

loadcell or calibration device.

4 Zero the load reading on the calibration device.

5 Press the Zero key on the control console to zero the machine load display.

6 Ensure that UP is shown as the Direction. If DOWN is displayed, press the key under

DIRECTION so that the display shows UP.

7 Ensure that CAL TENSION is displayed above the 3rd key. If CAL COMPRES'N is

displayed, press the 3rd key so that the display shows CAL TENSION

8 The crosshead speed is selected using the numerical keypad as shown in the table

below. Note that the number 0 will stop the crosshead and hold the load. Do NOT press

the ■ (Stop) key because the load may drop when the load pulls the crosshead back.

KEY SPEED

1 10 mm/min

2 5 mm/min

3 2 mm/min

4 1 mm/min

5 0.5 mm/min

6 0.2 mm/min

7 0.1 mm/min

8 0.05 mm/min

9 0.01 mm/min

0 ACTIVE STOP

Loading...

Loading...