Maintenance 73

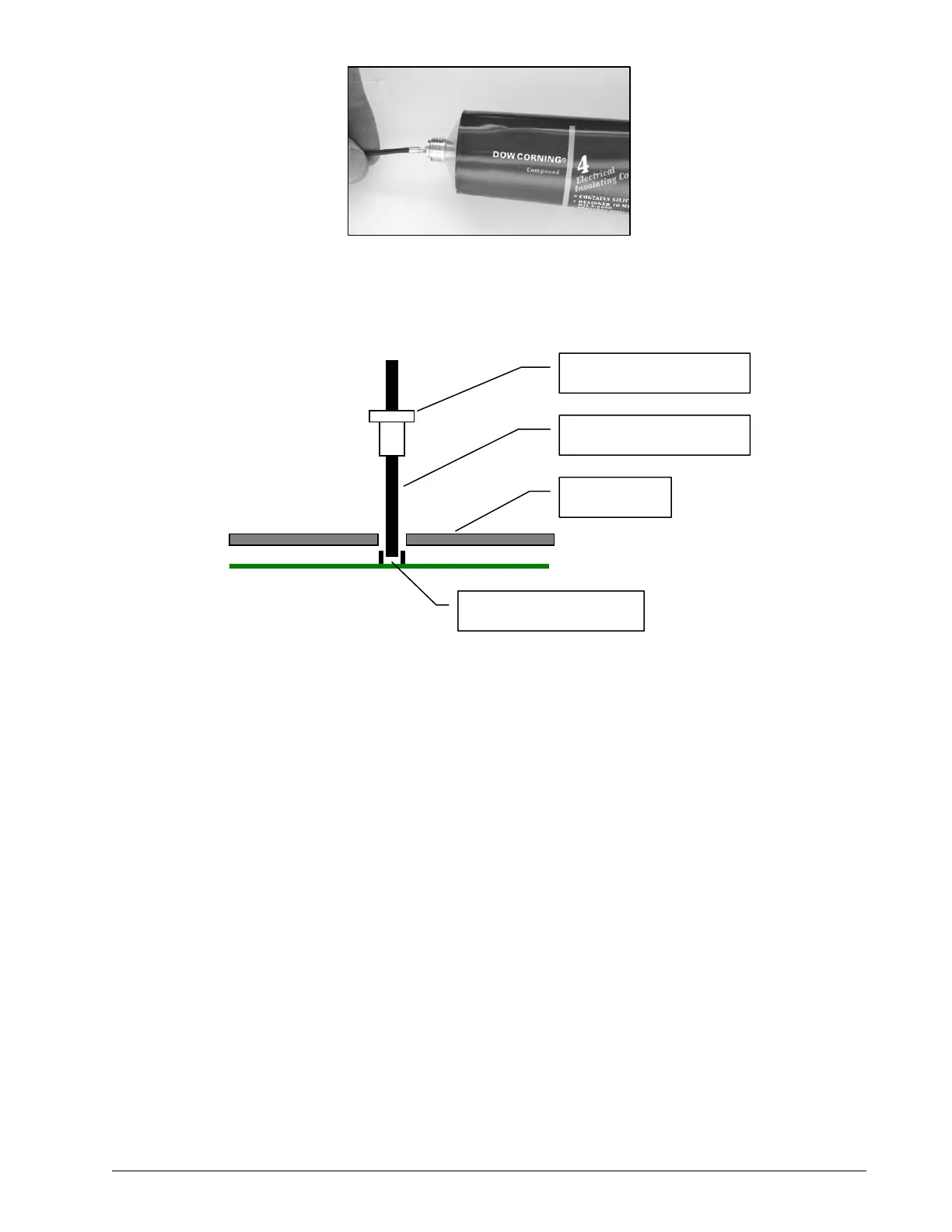

9. Hold the new antenna by the black plastic sheathing and guide it through the hole in the sensor

box. Carefully seat the antenna in its mating connector. When the antenna is correctly seated,

pulling on it will be met with light resistance.

10. Carefully re-thread, screw-in and tighten the white nylon hex bolt to secure the antenna in

place.

11. Reinstall the sensor if necessary (if removed from the boom or jib, an angle sensor will require

re-calibration during the installation procedure, see the angle sensor installation section of the

user manual).

12. Verify that the sensor functions properly.

Load Cells

W

ARNING

! Heavy shock may affect load indication accuracy. Inspect the load cell regu-

larly for clearly visible dents or scratches. Test the load indication if collision damage is

visible.

Reading Accuracy

LSI flat bar load links are pre-calibrated at the factory. No “zeroing” or other calibration is required

on installation. Each link is heat treated to age the steel and ensure stable readings for many

years; the load cells are individually temperature compensated to guarantee accuracy. LSI flat bar

load links are calibrated to indicate between 100% and 104% of their Safe Working Load (SWL).

LSI load pins, line riders and compression cells must be calibrated at installation and every time

thereafter the installation, the load sensor or the transmitter is changed.

White nylon hex bolt

TA011 Antenna

Sensor box

Antenna receptacle

Figure: Seating the antenna

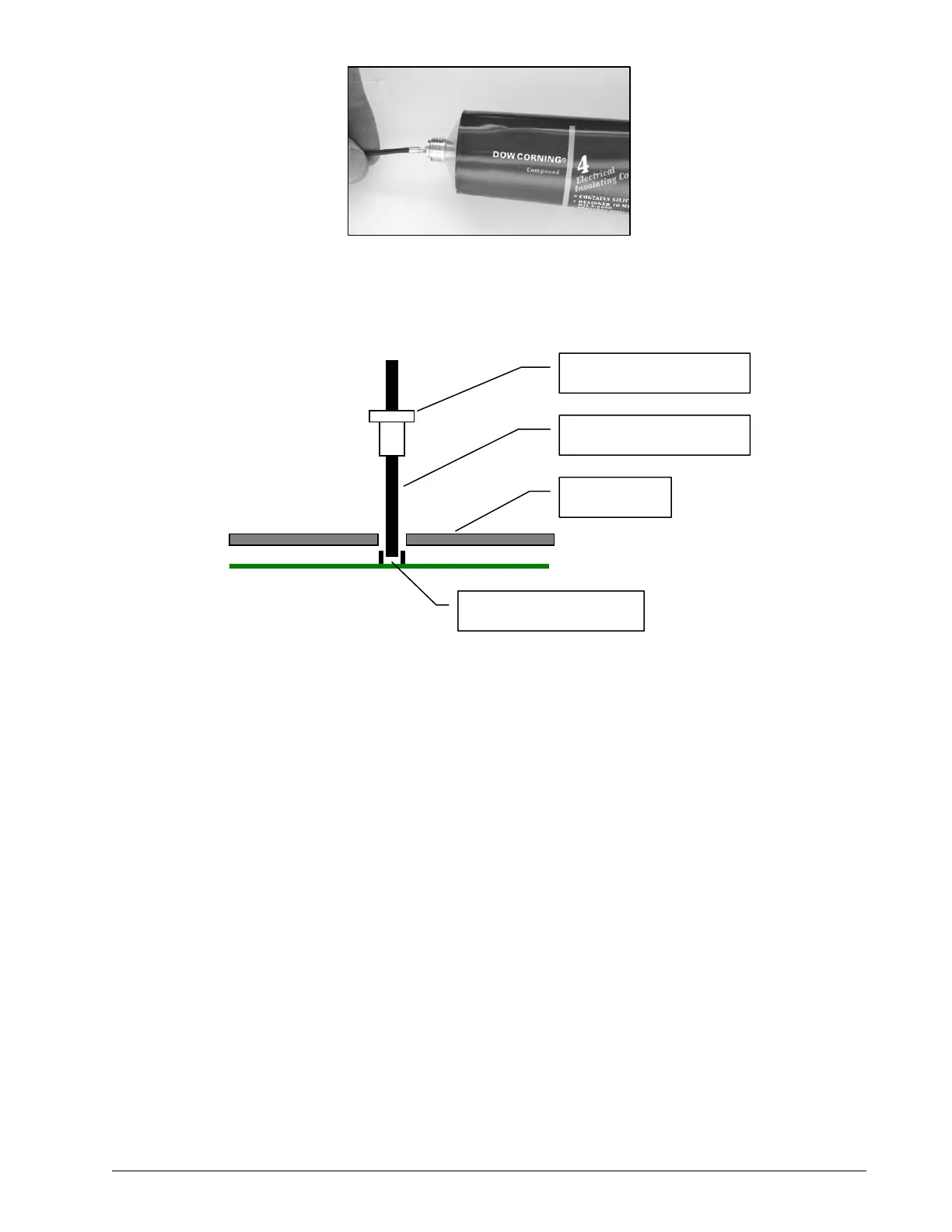

Picture: Coating the antenna foot

SkyAzúl, Equipment Solutions

Loading...

Loading...