54 The GS550 System

Rope Payout

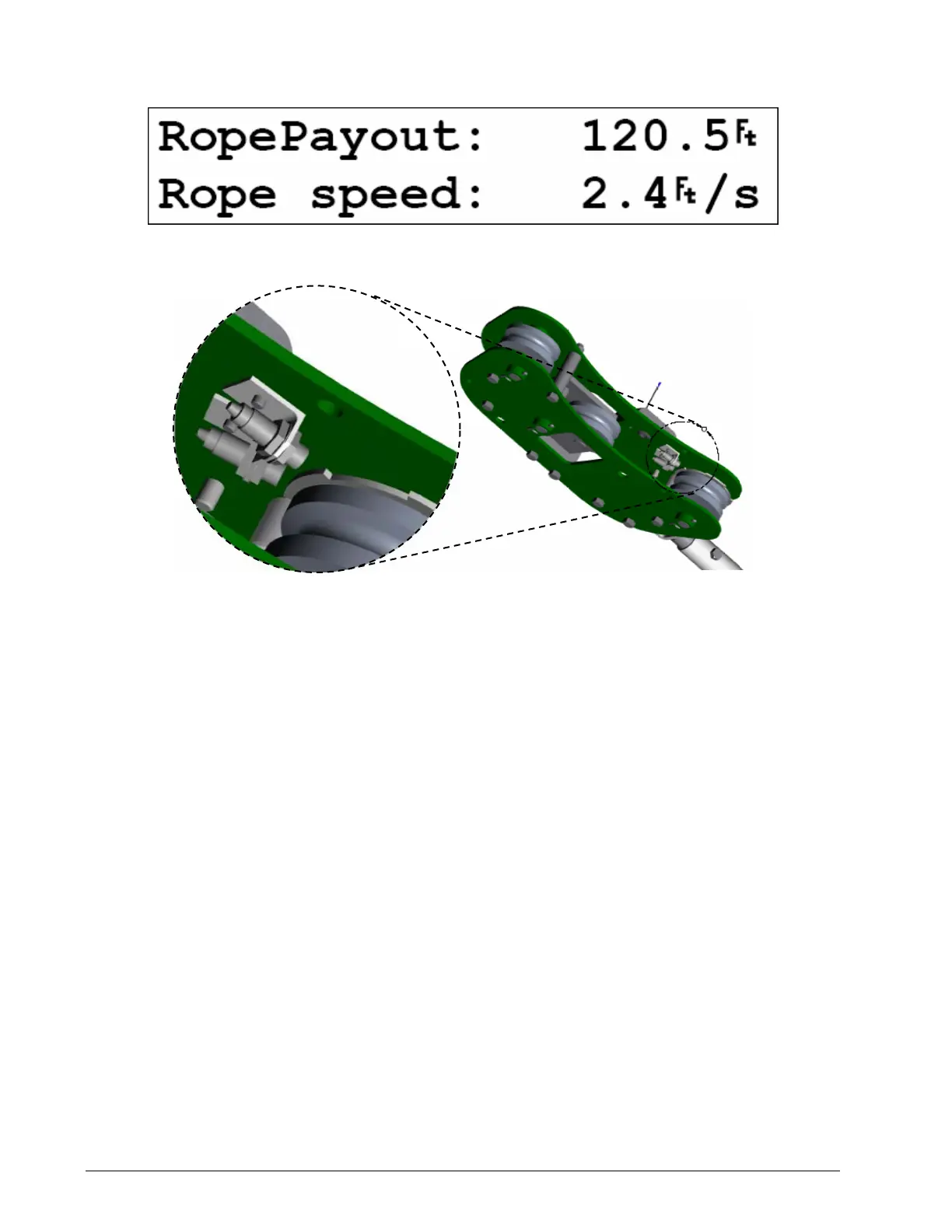

Typically the rope payout sensor is factory installed on the line rider load sensor. Alternatively the

rope payout sensor may be installed on an appropriate sheave. Power supply must be provided to

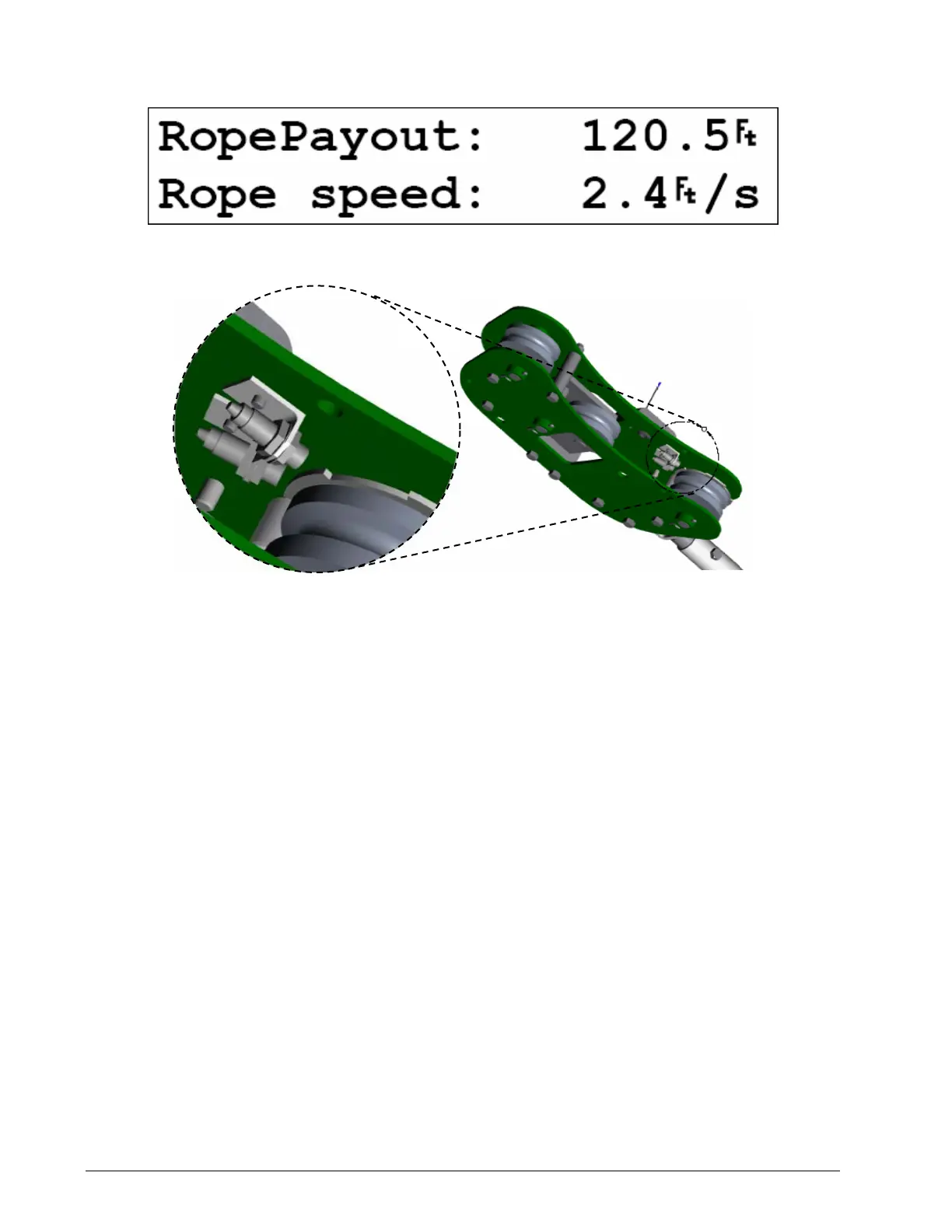

the rope payout sensor. A GS550 display can then be programmed to communicate with the

sensor and to indicate rope payout (length) and rope speed.

Rope Payout Calibration Procedure № 1: Mechanical Set-Up

1. Hoist up to reel in the wire rope fully.

2. Install the rope payout system.

3. Verify that the rope payout sensor is programmed in the sensor list (menu 4A1).

4. Zero the rope payout length in the Tare menu (see Operation, Display GS550, Keypad, Tare in

this manual).

5. Hoist down to pay out a known length of wire rope (for example: 20 feet).

6. Verify the rope payout indicated matches the actual length of wire rope paid out. If not then

follow Rope Payout Calibration Procedure № 2.

Rope Payout Calibration Procedure № 2: Correct with the GS550

If rope payout indicated does not match actual rope payout, and if it is not possible to easily correct

by following Rope Payout Calibration Procedure № 1, then follow this procedure. This procedure

requires hoisting up to fully reel in the wire rope, and then hoisting down to pay out a known length

of wire rope. For accurate calibration the “known length” paid out must be accurately measured.

1. Press Menu → Next → Next → Next → to go to menu 4) Installation.

Figure: Rope payout on a line ride

Figure: Rope payout displa

SkyAzúl, Equipment Solutions

Loading...

Loading...