48 The GS550 System

b. There must be direct unobstructed line of sight from the transmitter to the display; this

may not be required on cranes with a maximum boom length less than 100 feet (33 me-

tres).

c. The transmitter antenna must not be in contact with any metal object.

W

ARNING

! Do not weld in proximity to LSI sensor/transmitters.

2. Weld the mounting blocks where required.

3. Mount the load pin transmitter on the mounting blocks.

Load Pins, Line Riders and Compression

Cells: Calibration

Load pins, line riders and compression cells must be cali-

brated at installation and every time thereafter the installa-

tion, the load sensor or the load transmitter is changed.

Important! Do not recalibrate flat bar load links (part

numbers GC005, GC012, GC018, GC035, GC060,

GC100, and GC170).

This procedure requires two known weights. The first (light)

weight should be about 10% of load sensor capacity and not

less than 5%. The second (heavy) weight should be over

50% of capacity, and absolutely not less than 25%.

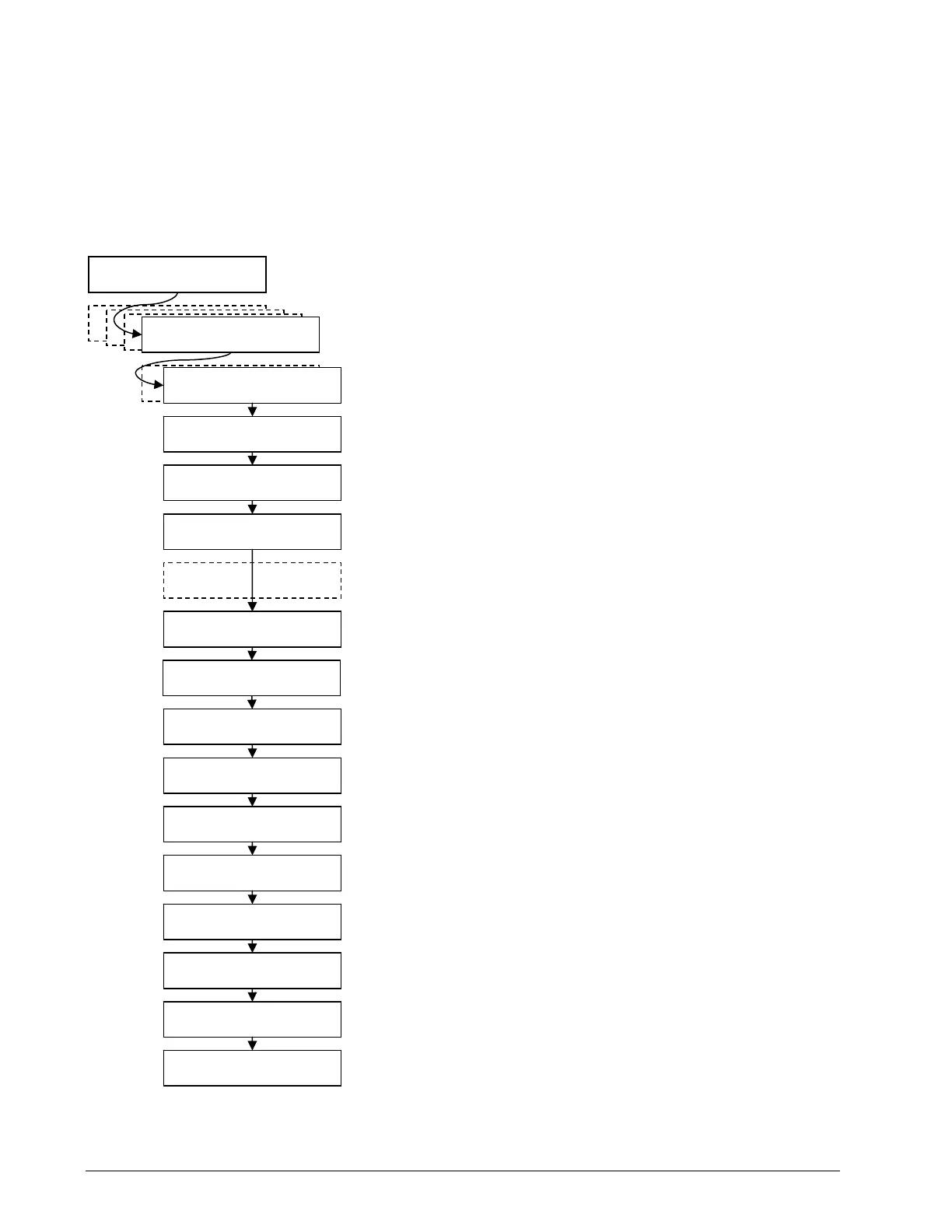

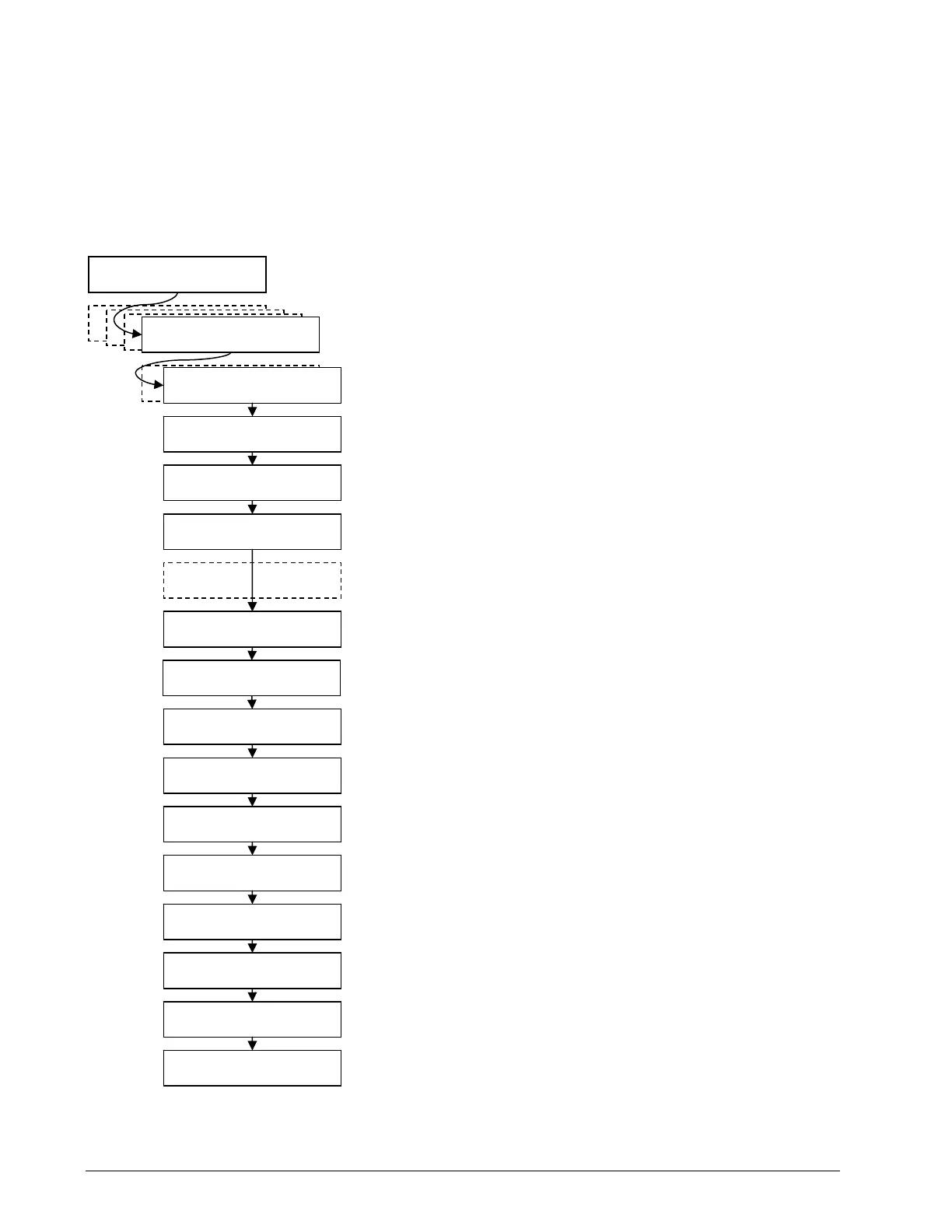

1. Press Menu → Next → Next → Next to go to menu 4)

Installation.

2. Press Enter → Next to go to menu 4B) Sensor Calibra-

tion.

3. Press Enter to go to the password page.

4. Use Back, Next, Up, and Down to enter the user pass-

word, and then press Enter to go to 4B1) Automatic

Value Calibration Wizard.

5. Press Enter to go to 4B1A).

6. Use Back and Next to select the load sensor, and then

press Enter to confirm communication with the sensor is

possible.

7. Press Next to start the wizard.

8. Use Up and Down to adjust the actual parts of line on the

load sensor, and then press Next.

9. Note the units that will be used during the calibration

wizard, and then press Next.

10. Lift the first (lighter) known load, and then press Next.

11. Use Up and Down to adjust the load value displayed to

equal the actual known load lifted, and then press Next.

12. Lower the first load, lift the second (heavier) known load,

and then press Next.

13. Use Up and Down to adjust the load value displayed to

equal the actual known load lifted, and then press Next.

14. Note the new trim value, and then press Next.

Operation Display

1) Parts of Line

2) Crane Rigging

3) Display Settings

Enter user password:

aaa

4B1) Automatic value

calibration wizard

4B1A) No. x id: Gxxxxx

Load sensor

Communicating with

remote sensor

Load calibration

wizard. Press Next.

2/9) Confirm current

unit: (lb, kg, T, t)

3/9) Lift known

load No. 1: xxxx

4/9) Adjust actual

load No. 1: xxxx

5/9) Lift known

load No. 2: xxxx

6/9) Adjust actual

load No. 2: xxxx

7/9) Calib Result

Trim: xxx

8/9) Calib Result

Scale: x.xxxx

9/9) Press Enter to

save calib in sensor

4A) Sensor List

4) Installation

4B) Sensor Calibration

Figure: The automatic load

calibration wizard.

1/9) Enter actual

parts of line: 1

SkyAzúl, Equipment Solutions

Loading...

Loading...