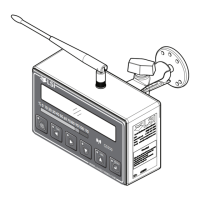

74 The GS550 System

SAE J-159 4.2.1 recommends load indicating devices should show not less than 100% of the

actual load and not more than 110% of the actual load.

Load Testing

LSI recommends testing the load cell every year for accuracy. The simplest way of testing a load

cell is to lift at least two known weights. A test weight should be known with an accuracy of ±1%. If

the load cell is installed at the boom tip dead end, all additional equipment such as blocks, slings,

sensors, etc. should also be known to an accuracy of ±1%.

Determine the accuracy of the tested system with the following formula:

(Reference: SAE-J-159 7.3)

The test loads must be significant relative to the load cell capacity. The minimum test weight is

about 20% of the safe working load; a good test weight is greater than 50% of the SWL. For

example, a 30 000 lb load cell on four parts of line has a SWL of 120 000 lb; the minimum test load

in this case would be 24 000 lb, a good test load would be 60 000 lb or more.

Care

Battery. Lithium batteries over than 18 months old (alkaline batteries over 6 months old)

should be changed at the first available planned inspection even if there is not yet a low

battery warning. This will avoid costly delays in the field.

Corrosion. Verify that no corrosion is visible on the battery holder inside the load cell

transmitter. If some trace of corrosion is visible, rub it off gently and put a small amount of

dielectric grease* on each battery holder post to protect the contact.

Mechanical stresses. Verify the load cell sides for dents or heavy scratches. The side of

the load cell under the transmitter box is the most sensitive region. Engraving a number in

this area will affect load cell accuracy and reliability. If the transmitter box has been hit and

the box does not fit perfectly to the underlying link, please call LSI to have it repaired. En-

graving on the transmitter box sides will not affect reading.

Seal. If the transmitter box has been removed it must be correctly resealed with RTV non-

corrosive silicone.

Antenna. Small scratches on the antenna will not affect radio communications. A heavy

bending of the antenna or bare sections on the wire may reduce the radio efficiency.

Hex bolts. The hex head bolts on the transmitter box are there to protect the antenna and

to hold the transmitter box on the load cell link. If one or both hex nuts are scratched, it will

not affect the load cell readings on operation. If the bolt head is bent or sheared verify the

transmitter box fits tightly to the load cell link before contacting LSI for replacement bolts.

*

Dow Corning dielectric grease #4

SkyAzúl, Equipment Solutions

Loading...

Loading...