p/n 18603-001, Rev. C LTV

®

1200/1150 Ventilator Service Manual Page 7-25

FVd Delivered Volume:

1) Apply 15 cmH

2

O to the flow valve differential transducer at the high side port and verify

the FVd readout is within ± 0.5 cmH

2

O of the applied pressure.

2) Disconnect the tube from the syringe to the high pressure port of the valve differential

transducer so the connection is open to ambient air. When the displayed value

stabilizes, verify the FVd readout is within ± 0.5 cmH

2

O.

FDw Monitored Volume:

1) Apply 30 cmH

2

O to the Flow Differential transducer at the high side port and verify the

FDw readout is within ± 0.5 cmH

2

O of the applied pressure.

2) Disconnect from the ventilator so the connection is open to ambient air. When the

display value stabilizes, verify the FDw readout is within ± 0.5 cmH

2

O.

FDb Inspired Volume (LTM Only):

1) Apply 30 cmH

2

O to the Flow Differential transducer at the low side port and verify the

FDb readout is within ± 0.5 cmH

2

O of the applied pressure.

2) Disconnect from the ventilator so the connection is open to ambient air. When the

display value stabilizes, verify the FDb readout is within ± 0.5 cmH

2

O.

O

2

Oxygen Inlet Pressure:

1) Apply 50 PSI to the high pressure oxygen inlet port and verify the readout is applied

pressure ± 1 PSI.

2) Disconnect from the ventilator so the connection is open to ambient air. When the

display value stabilizes, verify the readout is 0 ± 0.5 PSI.

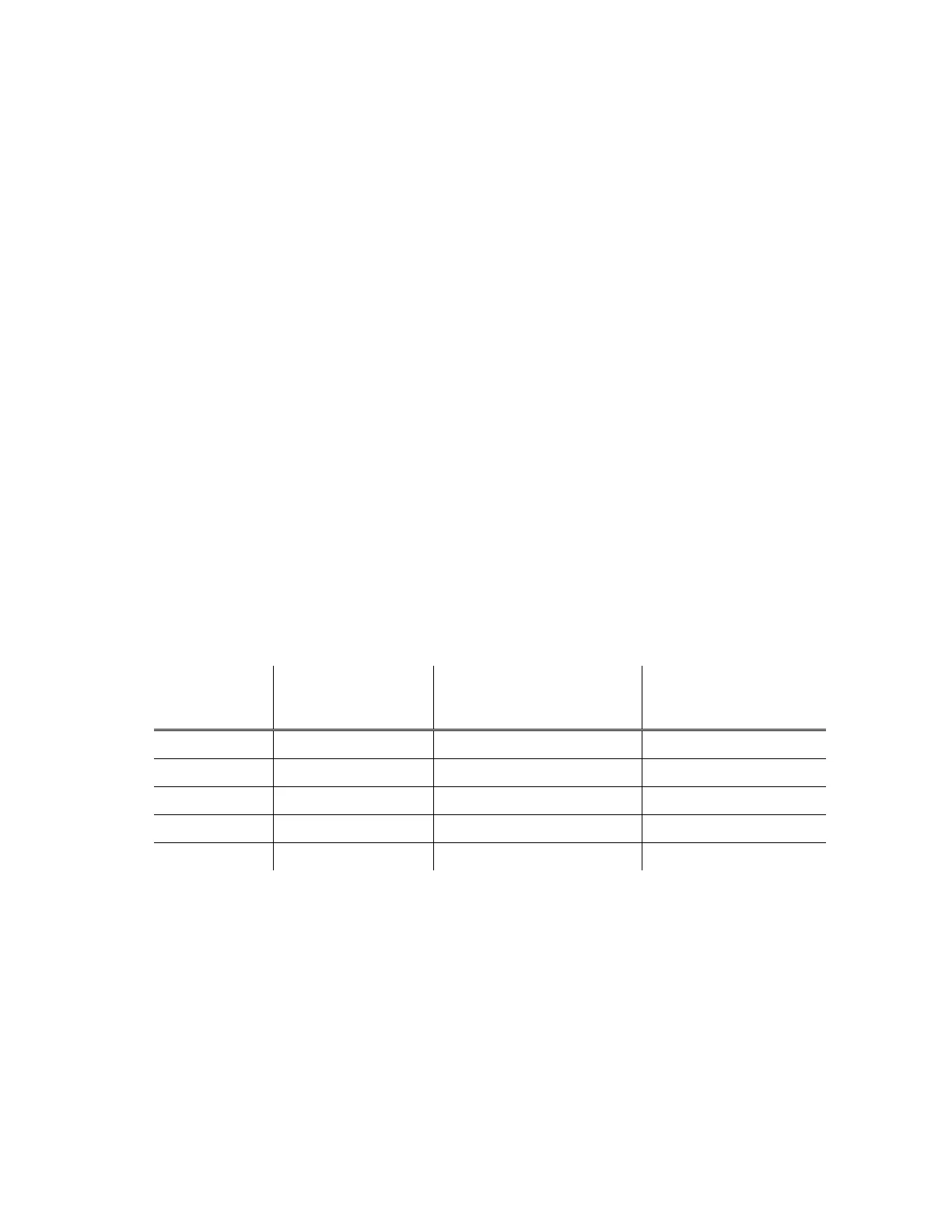

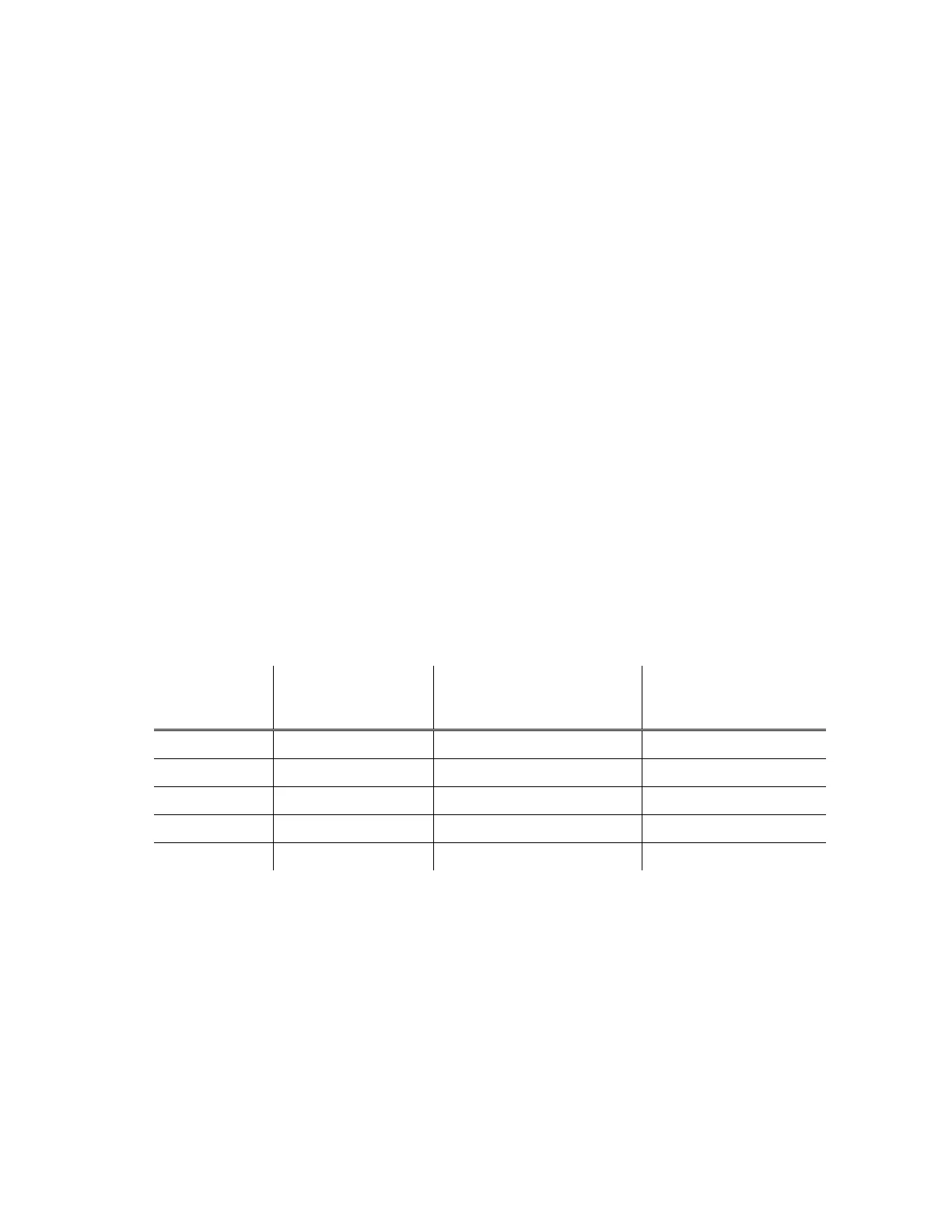

Transducer Tolerance Variance Table:

Transducer

Acceptable

transducer

tolerance range

Recalibrate transducer if

variance to tolerance is;

Replace analog board

if variance to

tolerance is;

AP ± 0.5 cmH

2

O >0.5 but < 2.5 cmH

2

O >2.5 cmH

2

O

FVd ± 0.5 cmH

2

O >0.5 but < 0.75 cmH

2

O >0.75cmH

2

O

FDw ± 0.5 cmH

2

O >0.5 but < 1.5 cmH

2

O >1.5 cmH

2

O

FDb ± 0.5 cmH

2

O >0.5 but < 1.5 cmH

2

O >1.5 cmH

2

O

O

2

± 1.0 PSI >1.0 but < 2.5 PSI >2.5 PSI

• If transducer recalibration is indicated, recalibrate that transducer (see Chapter 6 -

Maintenance & Calibration for instructions) and repeat the test.

• If analog board replacement is indicated, replace the analog PCBA. See Analog Board

Assembly in Chapter 8 for instructions and repeat the test.

• If the results for the transducers are within tolerance, perform the flow valve Accuracy

Checkout tests to determine accuracy of the flow valve.

Loading...

Loading...