p/n 18603-001, Rev. C LTV

®

1200/1150 Ventilator Service Manual Page 7-17

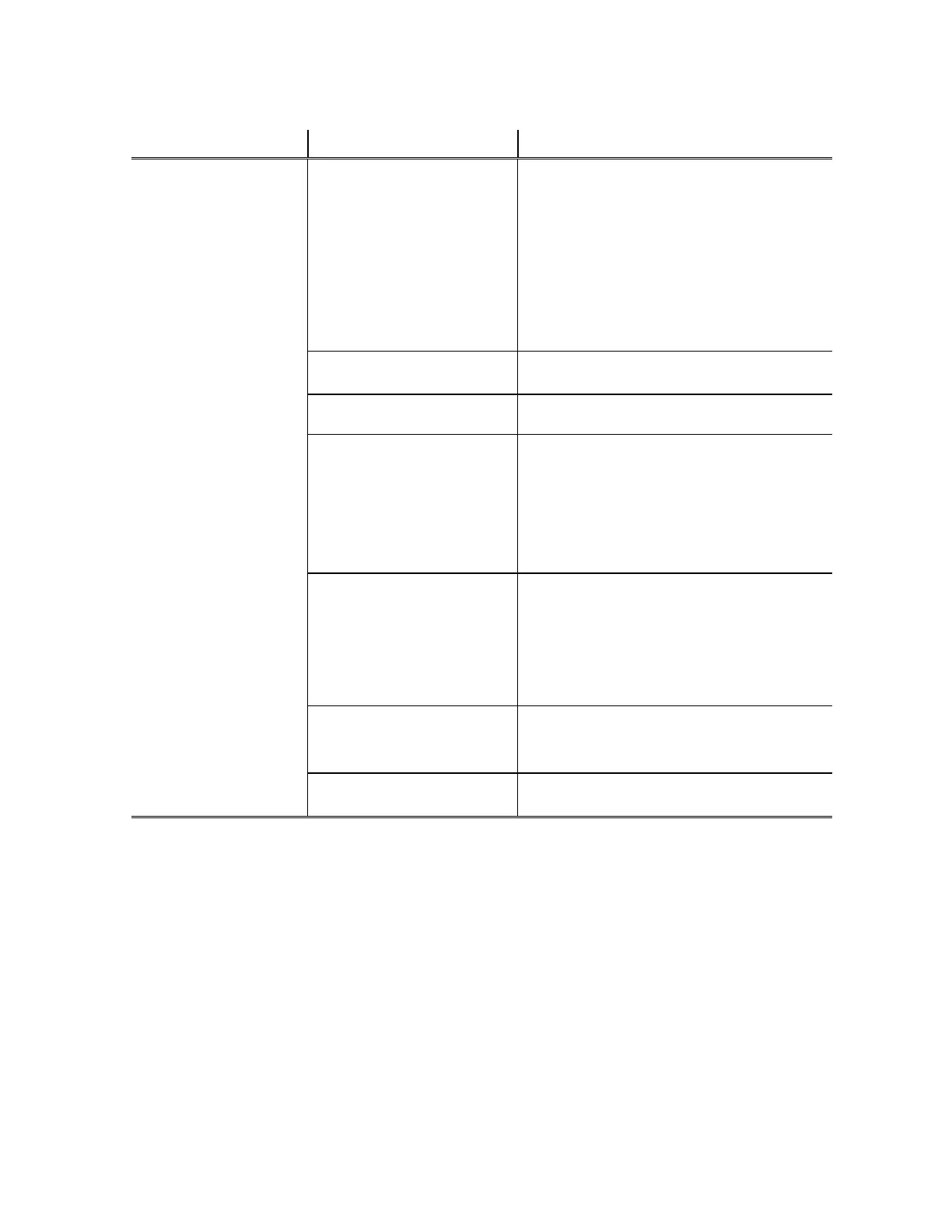

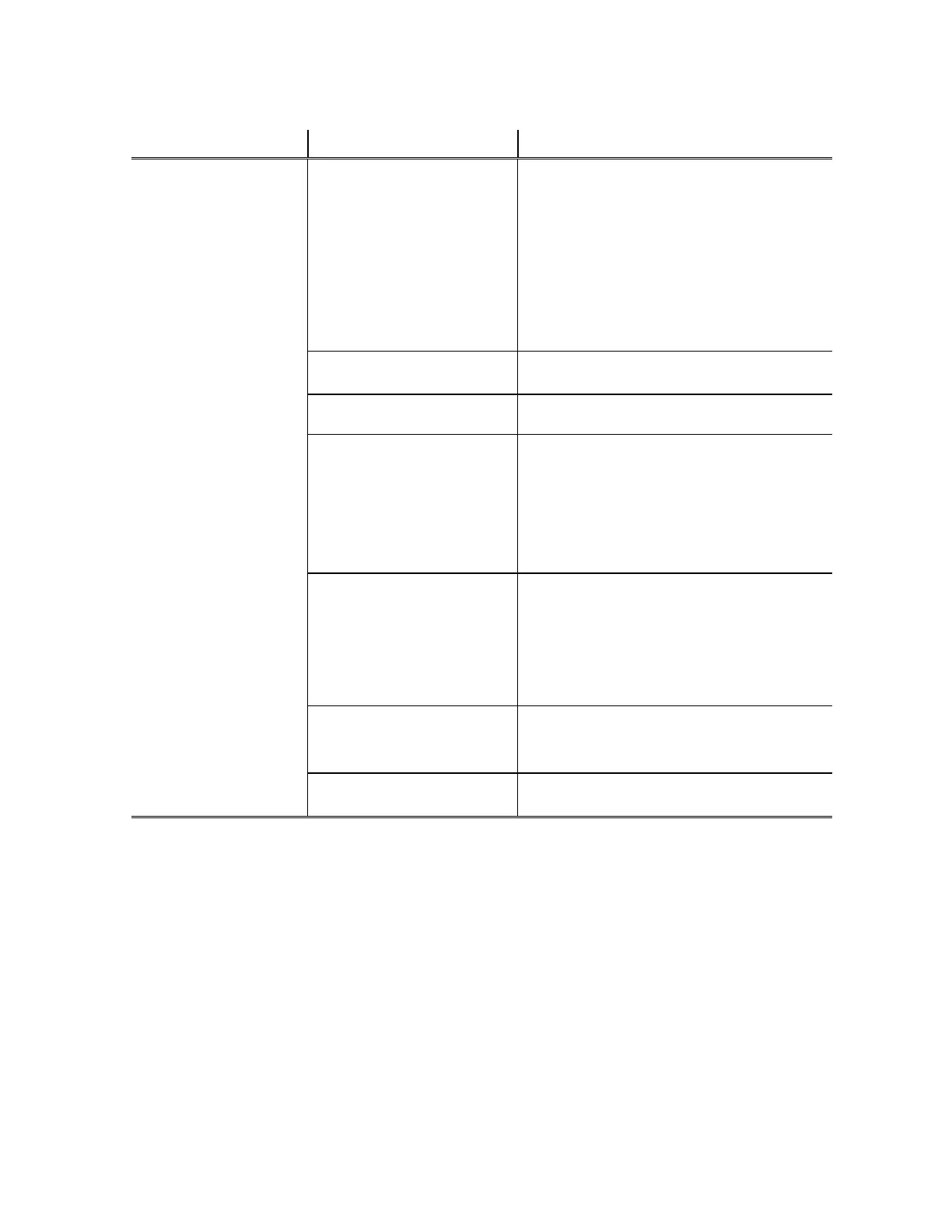

Symptoms Possible Causes What to Do

O

2

inlet flow too low when

Low O

2

Source selected.

Verify the low pressure O

2

inlet has been

correctly calculated and set using the

Input O

2

Flow Chart.

Pulmonetic Systems recommends the use

of an O

2

monitor to verify delivered O

2

%.

Adjust the entrained O

2

flow so the

monitored value shows the desired FIO

2

.

(See the LTV

®

1200 Ventilator Operator's

Manual for information on using the Low

O

2

Source and O

2

% features.)

Rolled or leaking flow

valve inlet gasket.

Replace flow valve inlet gasket (see Flow

Valve Assembly in Chapter 8).

Flow valve output is high.

Perform the Advanced FiO

2

Diagnostic

Procedures, see page

7-27.

Failed calibration.

Recalibrate the vent. See Chapter 6 -

Maintenance & Calibration for instructions.

If the problem reoccurs after careful

recalibration, a transducer may be drifting

excessively. Replace the analog board.

See Analog Board Assembly in Chapter 8

for instructions.

Internal flexible tubing

occluded or pinched.

Internal flexible tubing has

pinhole leaks or leaking at

connections.

Open the vent and verify that none of the

flexible tubes connected to the solenoid

manifold, analog board, oxygen blender or

flow valve are pinched or leaking. See

Solenoid Manifold Assembly or Analog

Board Assembly in Chapter 8 for a routing

diagram.

Defective or leaking

solenoid manifold.

Defective solenoid.

Replace the solenoid manifold. See

Solenoid Manifold Assembly in Chapter 8

for instructions.

O

2

% is low.

Incorrect O

2

blender

solenoid output flow.

Perform the Advanced FiO

2

Diagnostic

Procedures, see page

7-27.

Loading...

Loading...