IMPULSE®•G+ & VG+ Series 4 Instruction Manual – February 2017

5-28

NOTE: If an application requires Load Check to be bypassed, an MFDI may be programmed to 69

(N.O.) or 6A (N.C.)

NOTE: Upon completion of the Load Check set-up process, the drive will automatically set

C05-01 to 1.

NOTE: If an error occurs during the Load Check set up, the load being lifted causes current or

torque to exceed 250%. Increase Holding Time and Testing Time, and decrease the load

weight.

Clearing a Load Check Alarm (LC)

A Load Check alarm/fault can be reset by pressing the RESET key on the keypad.

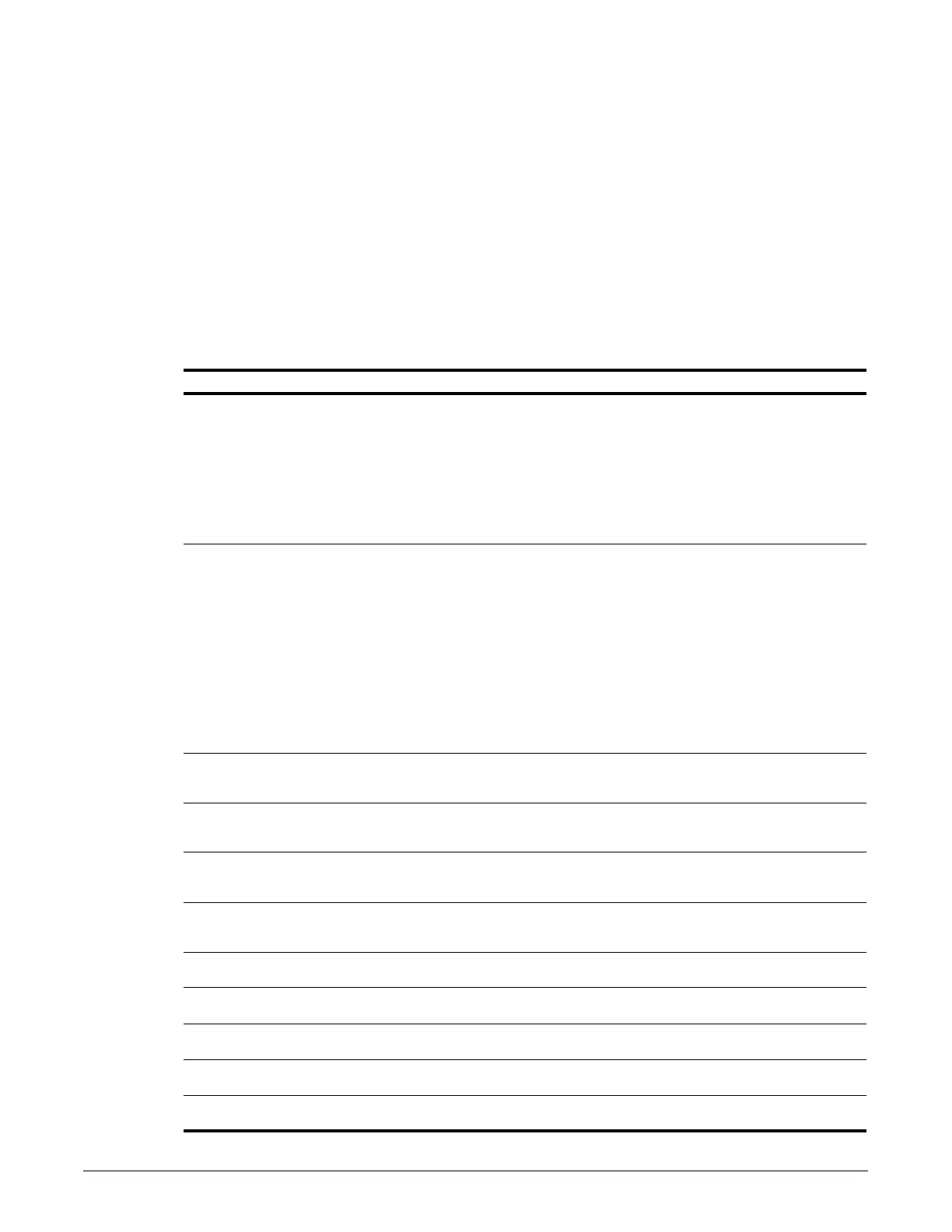

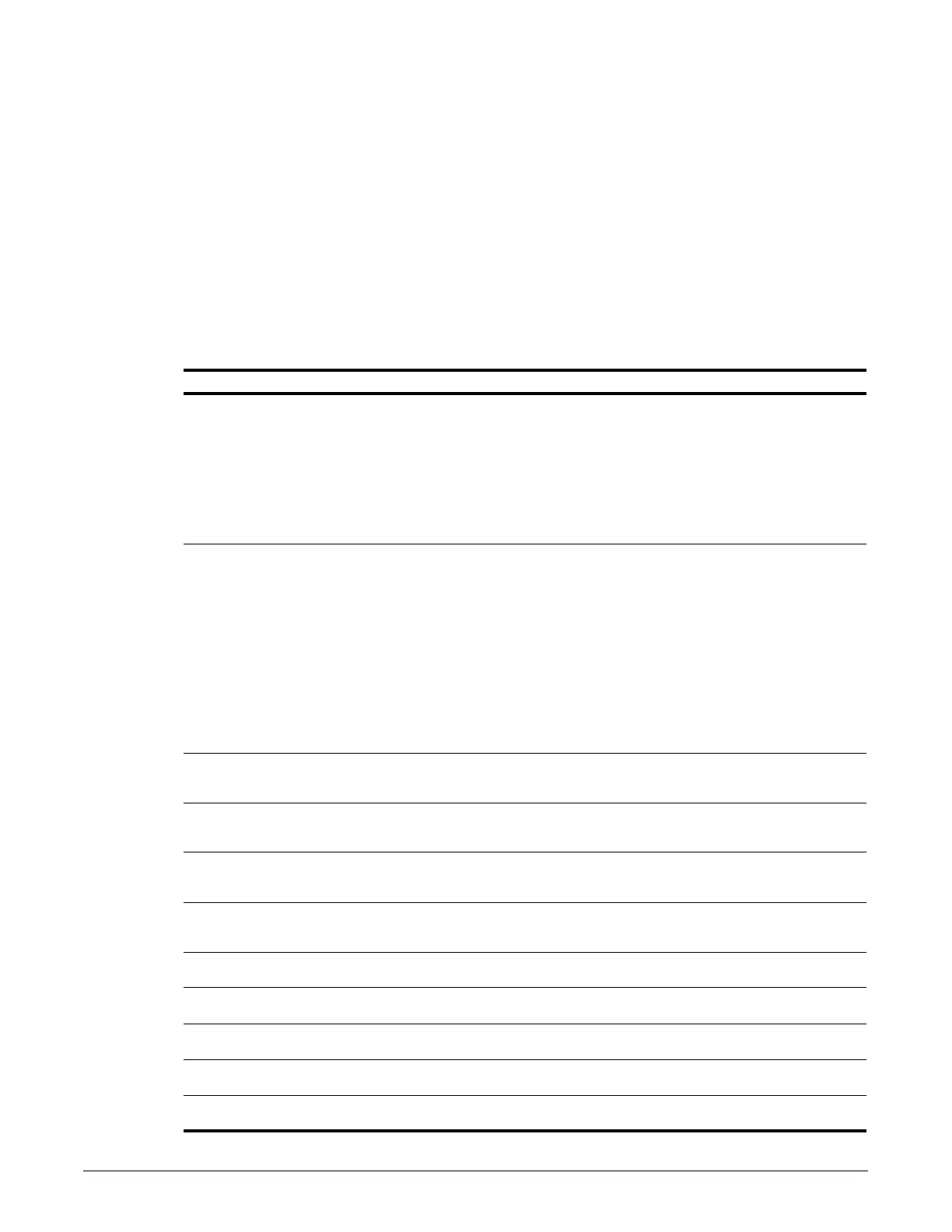

Table 5-28: Load Check II Parameter Settings

Parameter Display Function Range Default

C05-01 Load Check Determines whether Load Check is

enabled.

0–9 0

0 Disabled Disables Load Check II Function

1Hold &

Measure

Checks per Holding and Testing Time

3 Immediate Immediately faults when I/T level is

exceeded

9 LC Set Up Set up Load Check II

C05-02 LC Alarm Action Action at Load Check alarm or fault 0–5 4

0 Alarm Only L.C. blinking, can continue raising

1 Decel to Stop Allows lower only

2 Coast to Stop Allows lower only

3Fault Stop Fault contacts change state - requires

reset

4 Use B3-03

Method

Allows Lower only

5 B03-03 with

Reset

Stopping method is B3-03. Allows Lower

Only. Alarm will be reset when load is

lowered.

C05-03 Holding Time Sets the time to hold the output frequency

allowing the output current/torque to

stabilize.

0.00–2.55 sec 0.15

C05-04 Testing Time Sets the time (after the Holding Time) for

comparing output current/torque to values

for a particular LC Zone being tested.

0.00–2.55 sec 0.25

C05-05 I/T Margin Acc Sets the margin for Load Check detection

during acceleration. A setting of 00 is the

most sensitive.

0–50% 5

C05-07 I/T Margin Sets the margin for Load Check detection

at speed agree. A setting of 00 is the most

sensitive.

0–20% 5

C05-08 Alarm Speed Sets the maximum lowering speed after

an LC alarm.

0.0–30.0 Hz 6.0

C05-09 I/T Level 01 Current/Torque values detected during LC

set up for Zone 01

0–250% 0

C05-10 I/T Level 02 Current/Torque values detected during LC

set up for Zone 02

0–250% 0

C05-11 I/T Level 03 Current/Torque values detected during LC

set up for Zone 03

0–250% 0

C05-12 I/T Level 04 Current/Torque values detected during LC

set up for Zone 04

0–250% 0

Loading...

Loading...