Big-End Bearings

Inspection / Disassembly

A5.05. 02.04.01.00

15000, 30000

M20

en / 30.05.2000 IB021344 3/3

02

Ĺ

2. Removing the big-end bearing cap

2.1 Turn crankshaft into a convenient

position for removing (crankpin 20°

before of TDC to the camshaft side).

2.2 Loosen big-end bearing bolts and

screw out off connecting-rod big end.

2.3 Lift bearing cap out of the crankcase.

2.4 Check the toothing in the joint faces of

connecting rod, big-end bearing cap

and thread for damage.

3. Removing the bearing shells

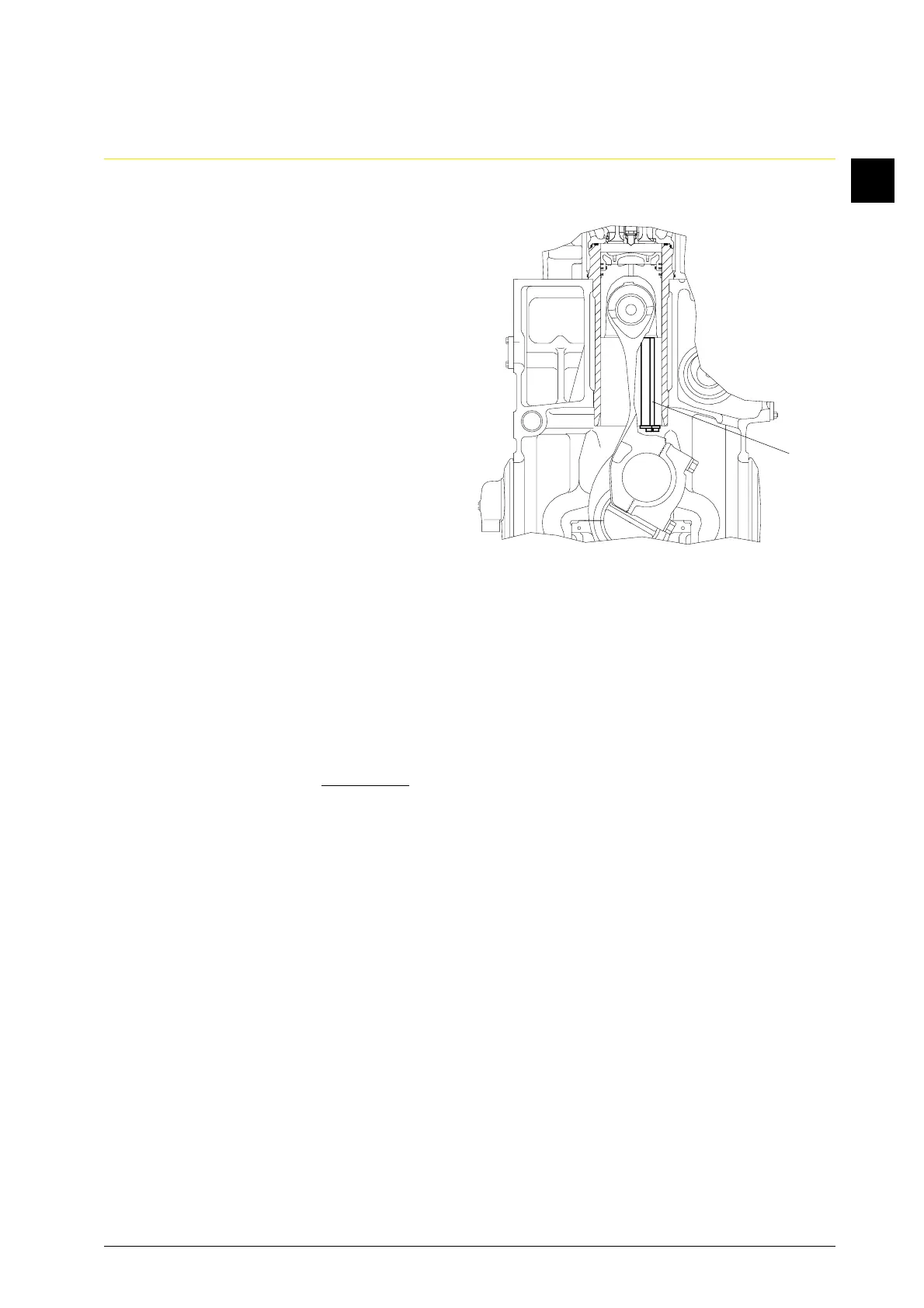

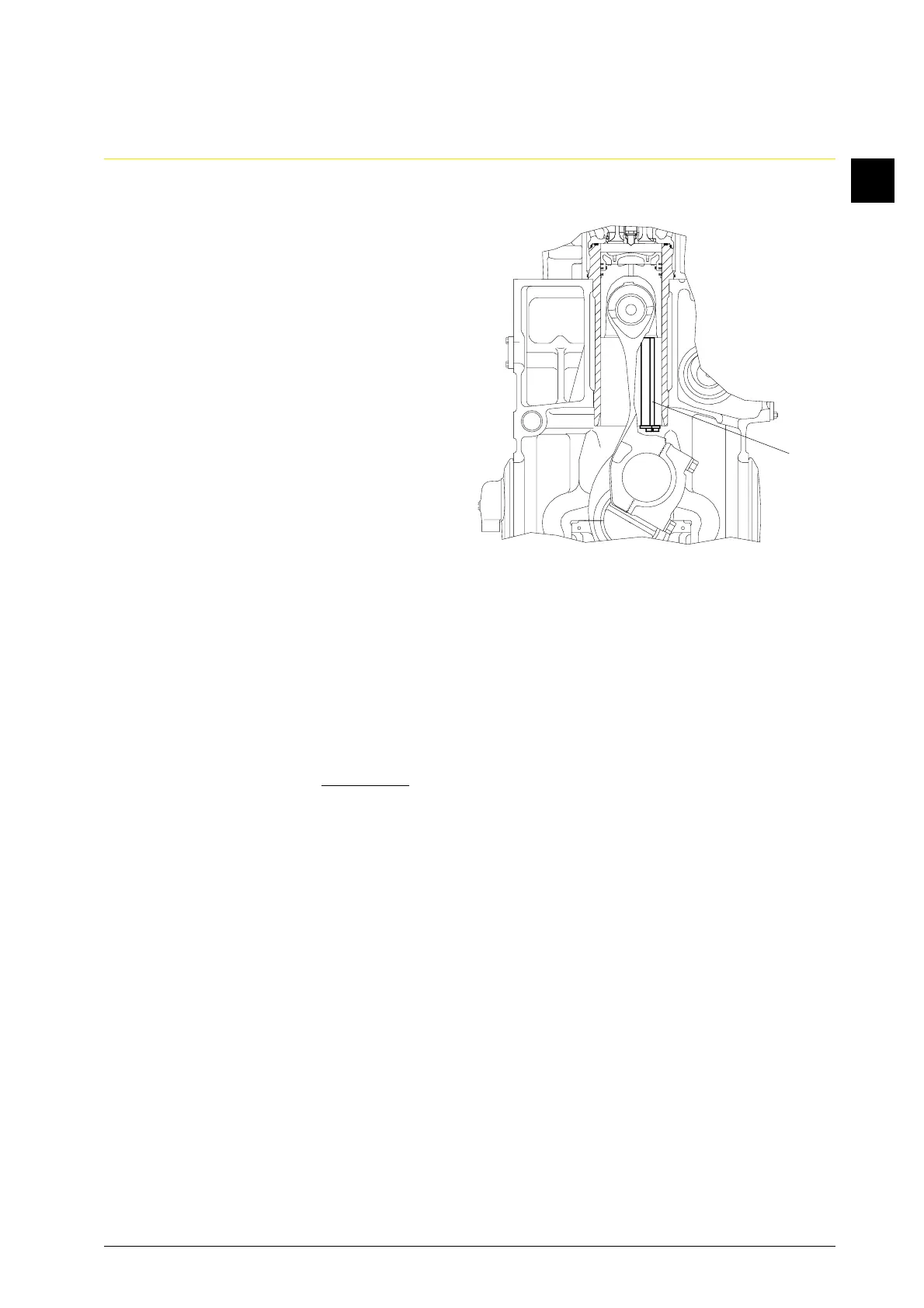

3.1 Move piston to TDC position, fit piston

suspension device (Fig. 3/W1) and

move crankshaft carefully to camshaft

side until the piston rests on the

suspension device and the crankpin

swings out of the connecting-rod big

end.

3.2 Remove bearing shells from crankpins.

3.3 Bearing shells, rating/replacement

criteria:

• AL groove bearing: 02.03.09.nn.

W1

Fig. 3

Loading...

Loading...