Big-End Bearings

Inspection / Disassembly

A5.05. 02.04.01.01

15000, 30000

M20

en / 30.05.2000 IB021371 1/3

02

Ĺ

See also: 02.03.09.nn

Spare parts list: B1.05.02.2.2601

Time requirement: 1 Pers./ 0,50 h

Personnel qualification: Chief engineer, skilled engine hand

---------------------------------------------------------------------------------------------------------------------

Operating medium: Heavy fuel

Inspection:

a) of a big-end bearing after 15,000 h

b) exchange of all big-end bearings after 30,000 h

Tools:

Piston suspension equipment W1 2.9226-A

Torque wrench 60 - 420 Nm 3/4" W2 * 1.9454-060

Tightening angle gage big-end bolts W3 2.9180-A

Turning rod W4 * 2.9100-380

* not available as figure

Auxiliary material:

Molykote paste “G-Rapid Plus” **

** or a product of equal standard

Note:

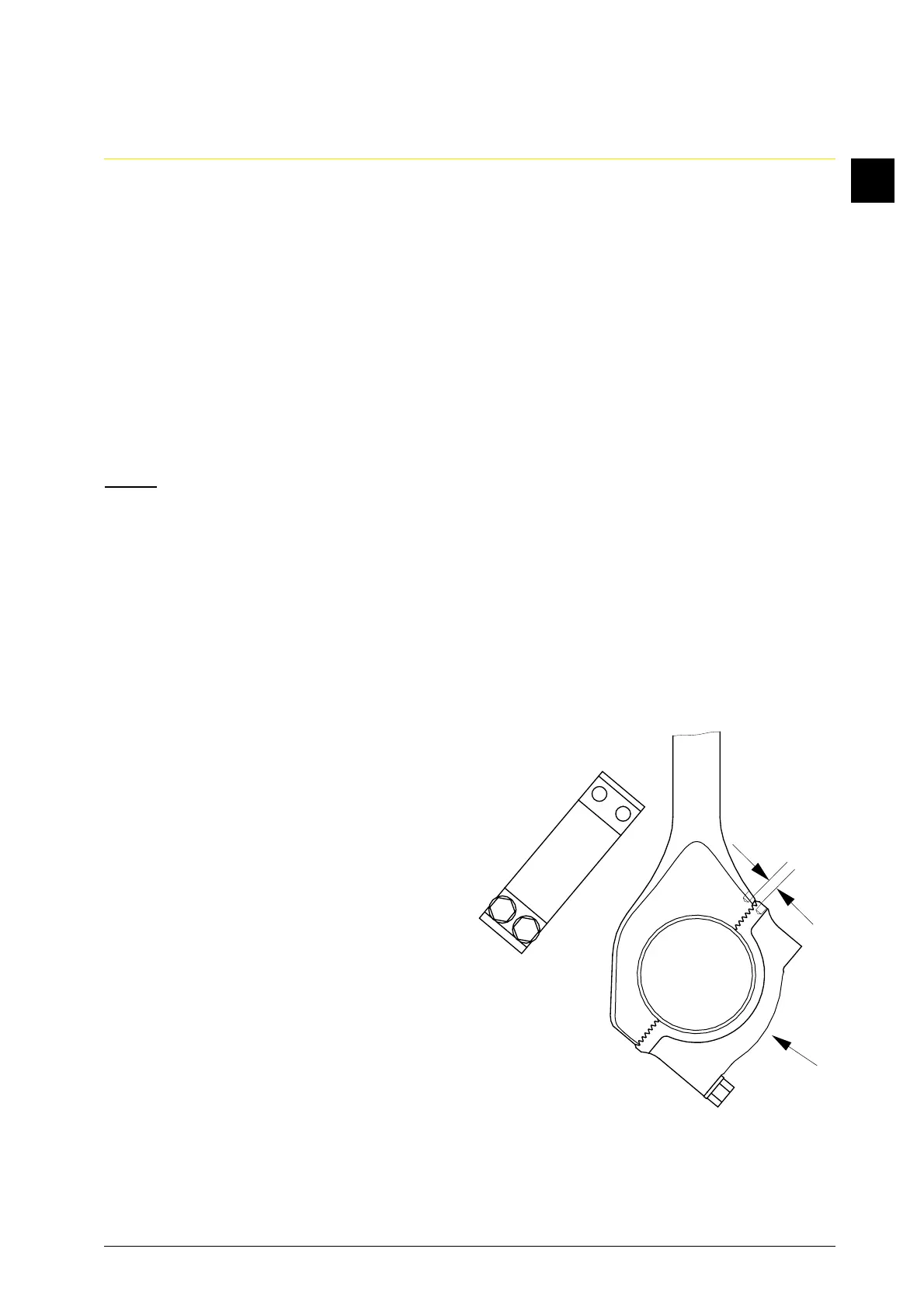

Coat threads and contact surfaces of

the bolts with Molykote paste “G-Rapid

Plus”. Before removing the big-end

bearing, measure clearance “K”.

Sequence of operations:

1. Clearance measurement

1.1 Turn crankpin approx. 20° before TDC

to camshaft side.

1.2 Loosen all big-end bolts.

1.3 Pretighten bolts 3 and 4 with a torque

M = 160 Nm

and measure dimension x

1

between the

bore holes on the camshaft side with

caliper gage (Fig. 1).

Y

Y

4

x

1

Fig. 1

3

Loading...

Loading...