Main Bearings

Maintenance / Reassembly

A5.05. 02.05.02.00

M20

en / 30.11.1999 IB001361 2/4

02

Ĺ

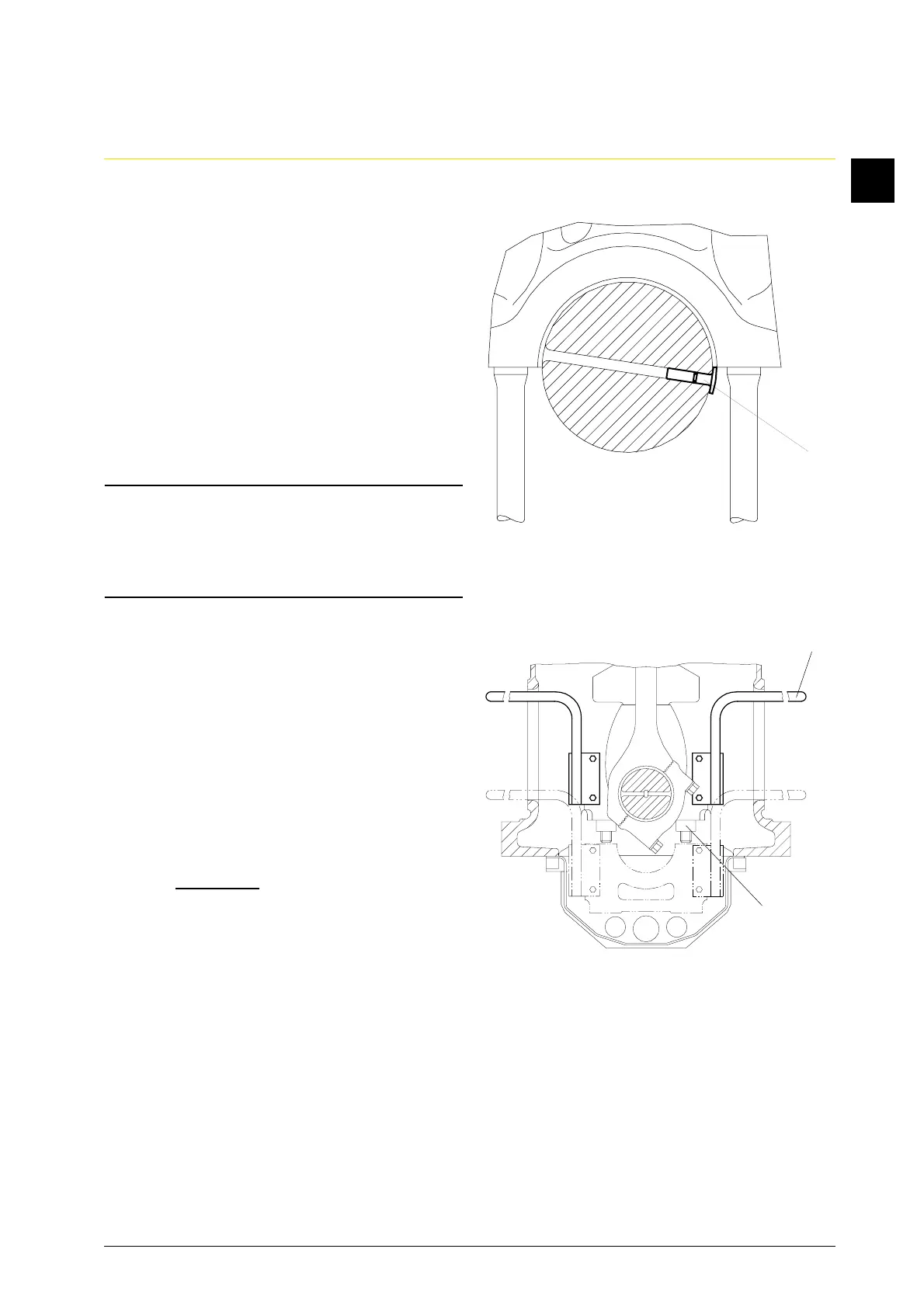

1.1 Lubricate working face of the top

bearing shell well, wipe bearing back

dry and press bearing shell into the

bearing so far that the dog (Fig. 1/W7)

can be inserted into the oil bore of the

crankshaft.

1.2 Twist in top bearing shell. Thereby,

maintain central position of the bearing

shell. The fixing lug must slide into the

guide groove of the bearing seat.

1.3 Lubricate working face of the lower

bearing shell, wipe bearing back dry

and insert into bearing cap.

Attention:

The bearing guide groove for the lower

shell is on the camshaft side. Observe

fixing pin on the exhaust gas side in the

case of locating bearing cap.

2. Tightening of the bearing shells.

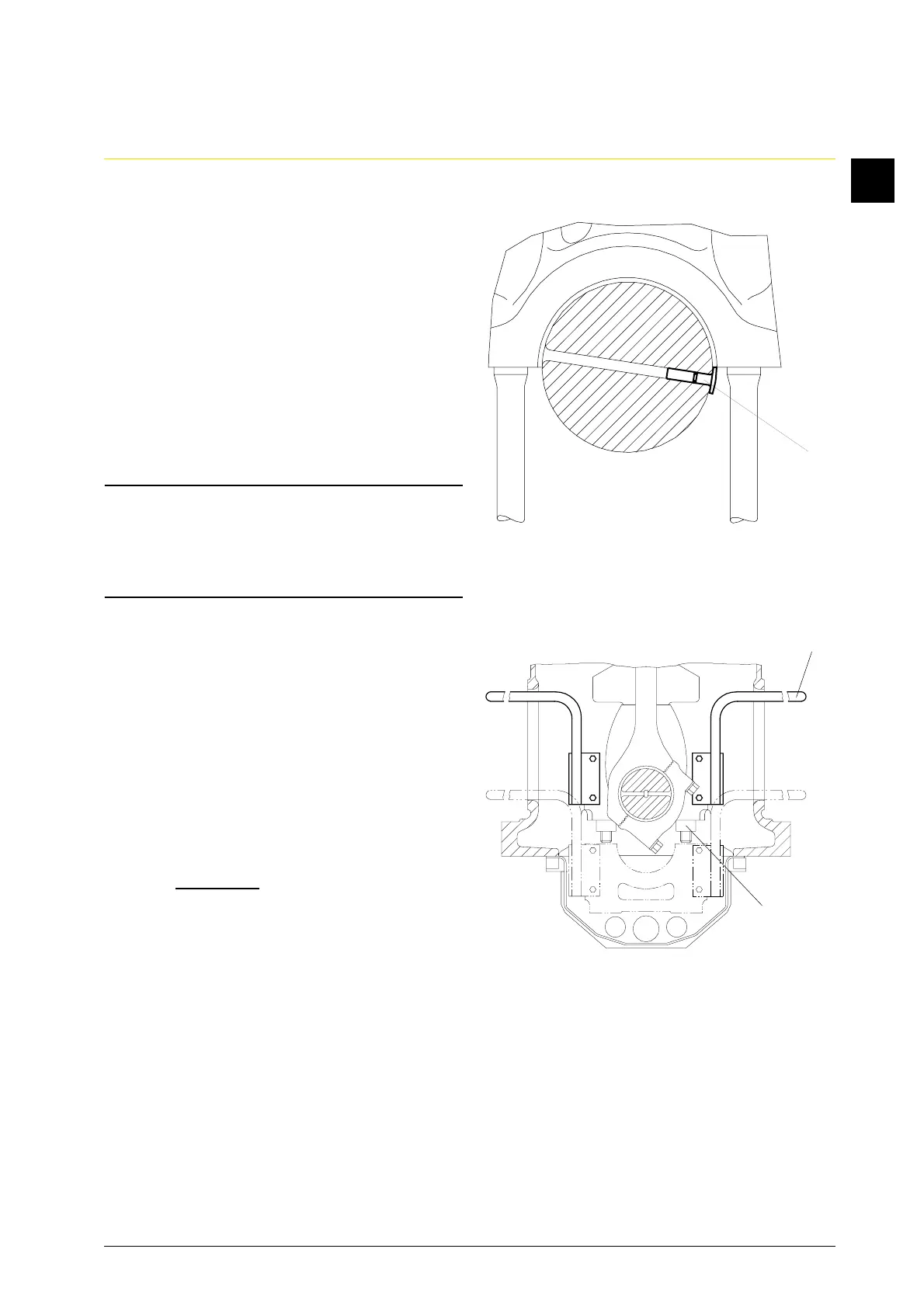

2.1 Lift the bearing cap with the aid of the

lowering device (Fig. 2/W6) over the

bearing bolts and screw round nuts (1)

uniformly on bearing bolts and tighten

hand-tight with pin (W5). Remove

lowering device (W6).

Note:

During the installation of new bearing

shells, the clearance “K” and in the

case of locating bearings, the axial play

(02.05.01.nn) is to be measured.

Fig. 1

W7

W6

1

Fig. 2

Loading...

Loading...